Industry 40

C.O.R.E. from United Grinding Group is Nominated for UX Design Award 2022

The intuitive digital solution has been selected from a pool of 300 submissions for its outstanding user and customer experience.

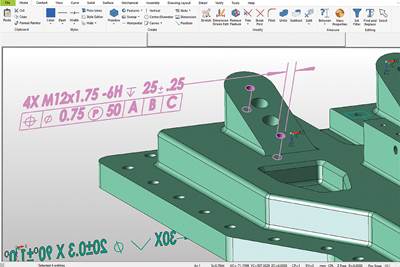

Read MoreThe Role of Model-Based Definition in Precise Mold Design

Model-based definition replaces technical drawings to communicate precise product definitions between designers and manufacturers.

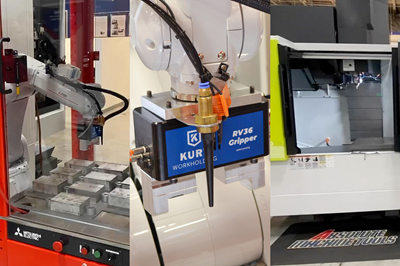

Read MoreTurnkey Package Enables Optimized Automation Integration

Together, Kurt Workholding and Absolute Machine Tools introduce a turnkey automation package, which features a Mitsubishi LoadMate Plus, Kurt 3600A Pneumatic Vise and Kurt RV36 Robotic Gripper working in tandem with a Tongtai VP-10 high-speed vertical machining center.

WatchRoadmapping Workshop Reveals Key Pain Points and Leverage Areas of Advanced Tooling Manufacturing

Oak Ridge National Laboratory and The University of Toledo, College of Engineering workshop reveals the challenges facing U.S. mold builders and identifies efforts needed to decrease dependence on offshore tooling.

Read MoreHow a Mold Builder Can Implement Industry 4.0

Properly planning the implementation of an Industry 4.0 system will yield short lead times, an improved bottom line and a more efficient shop floor.

Read MoreHere Are Your Top 10 Most-Read Features of 2021

A list of the most-viewed features in MoldMaking Technology from January to November 2021.

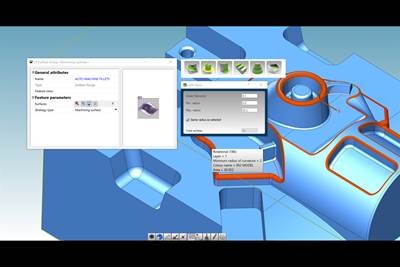

Read MoreThree CAD/CAM Automation Advances

Feature-, attribute- and script-based CAD/CAM automation ease programming and skilled labor challenges.

Read MoreFive-Axis Workholding Automation Console Supports Precise Positioning, High Clamp Force

Teknics has released the Zerolox XP 80Z Zero Point workholding automation console, which is designed for improved repeatability and high clamping force.

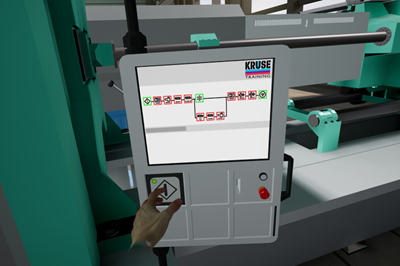

Read MoreFully Functional Molding Shop Floor Virtual Reality Supports Training Initiatives

Kruse Training is developing virtual reality (VR) classes for injection molding processing to prepare users for work on an actual shop floor as well as support mold shops’ hands-on process training initiatives.

WatchRenishaw Partners with Connecticut Center for Advanced Technology

Renishaw provides industrial metrology and additive manufacturing equipment to the Connecticut Center for Advanced Technology (CCAT) to implement digital technologies and prepare new talent for the industry.

Read More

.png;maxWidth=300;quality=90)