Turnkey Package Enables Optimized Automation Integration

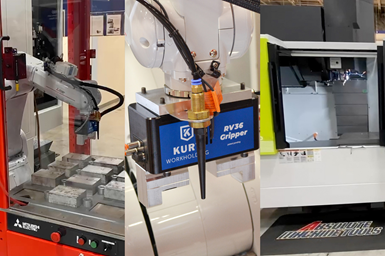

Together, Kurt Workholding and Absolute Machine Tools introduce a turnkey automation package, which features a Mitsubishi LoadMate Plus, Kurt 3600A Pneumatic Vise and Kurt RV36 Robotic Gripper working in tandem with a Tongtai VP-10 high-speed vertical machining center.

Kurt Workholding and its distribution partners at Absolute Machine Tools have created an automation package featuring a Mitsubishi Electric Automation LoadMate Plus plug-and-play cell, Kurt 3600A Pneumatic Vise and Kurt RV36 Robotic Gripper working in tandem with a Tongtai VP-10 mass production high-speed vertical machining center.

The Tongtai VP-10 has X-, Y- and Z-axis travels of 40.2" x 20.1" x 23.6" (1,021 mm x 510 mm x 600 mm). High-power servo motors produce 1,890 ipm (48 m/min) in X and Y, and 1,417 ipm (36 m/min) in Z. Acceleration in X, Y and Z is 1.18G, 1.0G, 0.7G respectively. A standard 10K rpm 20-horsepower direct drive spindle, and tool changer is able to hold as many as 30 tools. The standard Mitsubishi M80A control features a 10.4" (265 mm) touch screen.

Left to right: Mitsubishi LoadMate Plus, Kurt RV36 Gripper and Tongtai VP-10. Photo Credit: Kurt Workholding

Also featured in the demo package is the Kurt 3600A VersatileLock pneumatic vise and RV36 Robotic Gripper. Designed for precision clamping, the vise’s “Pull-type” action and AngLock jaws reportedly reduce stationary jaw deflection by at least 80%. A one-piece body and stationary jaw design reduce weight and increase strength while providing repeatable 0.0005 clamping capabilities. The RV36 Robotic Gripper also offers customizable, quick-change fingers in a compact, cost-effective package. Pneumatically actuated steel or aluminum finger configurations are available and attach to the vise using pull studs for changeability with a maximum payload of 50 lbs, and without the need for manual intervention.

Absolute Machine Tool customers can purchase Kurt Vises and RV36 Grippers as part of a package with the Tongtai VP-10 and Mitsubishi LoadMate Plus. The LoadMate Plus also packages as a stand-alone robot cell using an RV-8 Mitsubishi robot.

Related Content

-

Maintaining a Competitive Edge: EDM, Automation and Machining Technology Roundup

This month’s technology roundup features products, processes and services relating to EDM, automation and machining. For example, jig grinding for large molds, scheduling automation software, cobot integration, die sinker EDM and much more.

-

Reimagining Moldmaking with Technology

A look at some of the technology mold builders have expressed a growing interest in and are now actively investigating, including advancements in mold design, 3D printing, automation, machining, inspection and repair.

-

Products and Services for Multiple Moldmaking Needs

New year, new technology roundup! Featured here is a collection of product offerings, from profile milling cutters to industry-specific CAD/CAM software to innovative hot work tool steels.

_970x90 4.png;maxWidth=970;quality=90)

.png;maxWidth=300;quality=90)