Latest Maintain News And Updates

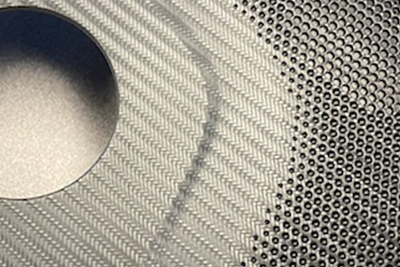

One-Stop Shop Simplifies Custom Surface Textures, Mold Performance

NPE 2024: Standex Engraving Mold-Tech specializes in managing every step of the project process, from texture design and engraving to preparing the tool for production.

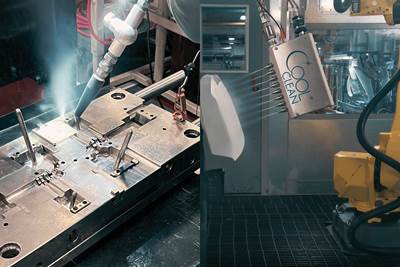

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreFiber Laser Welder Brings Flexibility to Mold Repair Operations

NPE2024: The Sisma SWA 450 F laser welder targets large or small mold repair, backed by intuitive software functions, a high-energy laser and an adjustable laser arm and head.

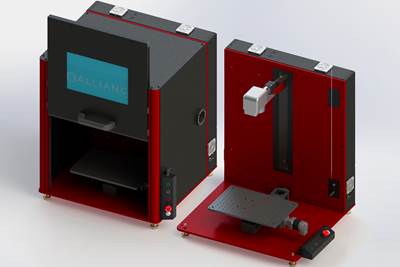

Read MoreLaser Engraving System Features MOPA Fiber Laser

NPE2024: The Advantage from Alliance Specialties and Laser Sales is a laser engraving system with a compact footprint, featuring a MOPA fiber laser.

Read MoreMold Maintenance Continues to Matter: Enhanced Training Program in a New Facility

I attended a MoldTrax mold maintenance workshop in 2019 and shared my experiences, and despite changes in ownership, the workshop's remarkable value endures, as discussed in a recent Q&A with the current leadership.

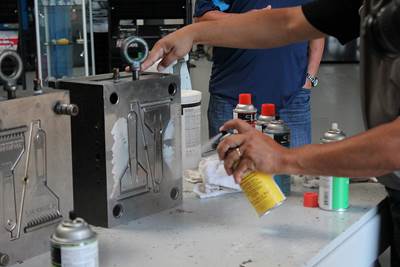

Read MoreHands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreFeatured Posts

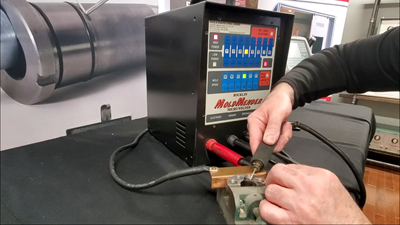

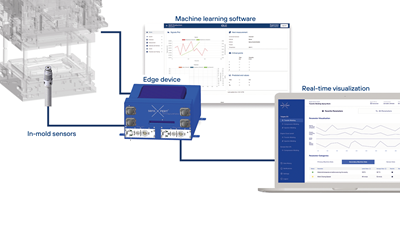

How to Implement a Remote Validation Process

A review of the setup and use of a remote mold validation kit.

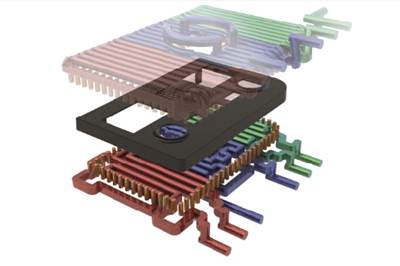

Read MoreHow to Maintain Heaters, Thermocouples, Valve Gates and Controls

An examination of real-world problems and solutions involving hot runner system maintenance.

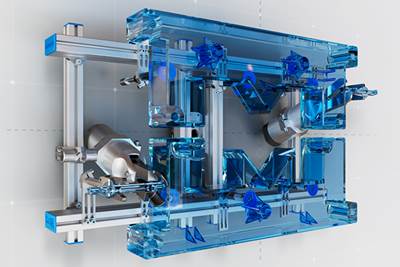

Read MoreHow to Use Simulation to Achieve a High-Gloss Surface Finish

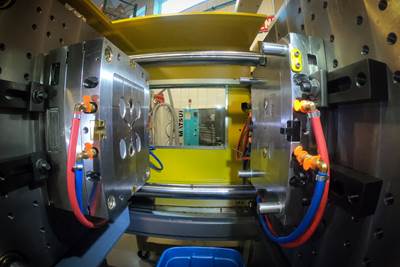

Combining simulation, conformal cooling, and a rapid heat and cooling process can predict and produce the required surface finish for high-gloss plastic parts.

Read MoreWhat You Should Know About Injection Mold Safety Straps

Every mold should have one in order to be safe and OSHA compliant.

Read MoreEditorial Advisory Board 2023-2026: Camille Sackett, Vice President of Sales and Marketing for Accede Mold & Tool

The 2023-2026 version of MoldMaking Technology's EAB features a new crew of industry professionals. Meet Camille Sackett

Read More3D Scanning Quickly Solves Tool Repair Problems

3D scanning supports the repair of molds with no history, drawings or design files.

Read More

.png;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)