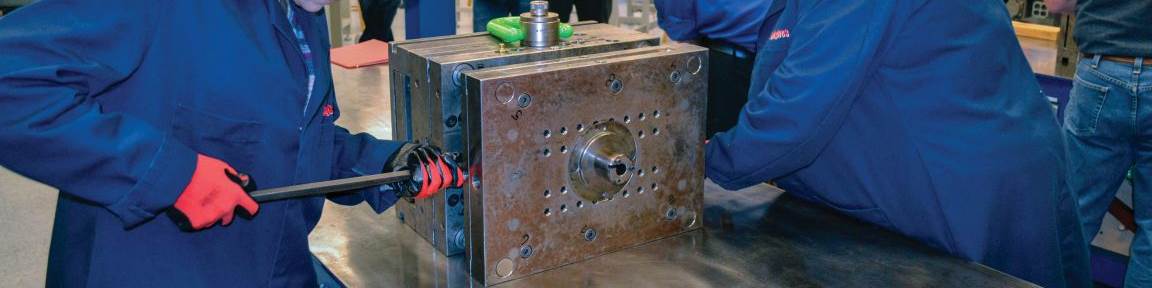

MoldMaking Technology editorial director Christina Fuges takes a pry bar to this injection mold for a lesson in proper disassembly for maintenance during an intensive three-day workshop. Photo Credit, all images: MoldTrax

I met Captain Jack and took a pry bar to him. Okay, let me explain. Captain Jack, or more commonly known as the “beast,” is the most challenging mold (with 48 cavities and a valve gate manifold system) presented to trainees at the MoldTrax mold maintenance training facility, which I was invited to participate in in 2019.

Now, I didn’t actually meet Captain Jack, but I did break down Husky Joe and got a good look at T-Rex and Dirty Bird, too. Each of these molds, designed with different complexity levels matched to the appropriate attendee skill level, is used to demonstrate the importance of choreographing mold bench work because proper mold maintenance is not freelance work; it is a process. This process demands effective communication among mold designers, processing engineers and repair technicians, as well as data. Now, let me share with you what I experienced during this training.

“Mold repair is the second most expensive budgetary item in a plastics molding facility.” This statement should make everyone stop and pay attention. The only way to change that figure is to change the culture, and we all know that culture change is tough.

The Setup

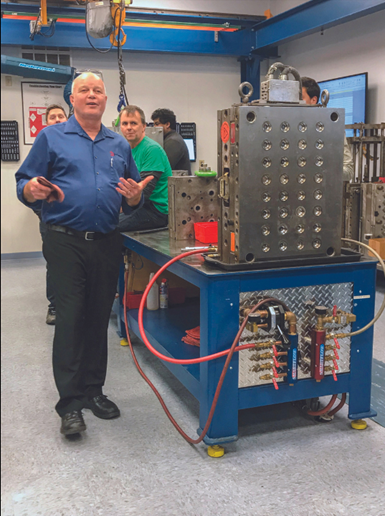

An intentionally designed toolroom equipped for hands-on training provides the perfect learning environment, enabling technicians to get their hands on a tool that has been “set up” with issues to cause them to struggle, ensuring maximum retention of information learned.

As you open the door to the MoldTrax training facility in Ashland, Ohio, you are standing in an intentionally designed toolroom, set up with equipment and a workflow mostly for medical-size molds that are 6,000-8,000 pounds or less, and ready for hands-on training. The environment includes maintenance benches optimized for mold assembly/disassembly, mold light bars, grinders, hoists, broken-down unscrewing and three-plate molds with status tags, damaged hot runner systems, workstations furnished with top-of-the-line Gerstner toolboxes and computers running MoldTrax data management software. Lastly, flat-screen TVs are scattered across the shop floor to provide an up-close-and-personal look at various mold maintenance and troubleshooting best practices.

The toolroom includes maintenance benches optimized for mold assembly/disassembly, mold light bars, grinders, hoists, broken-down unscrewing and three-plate molds with status tags, damaged hot runner systems and more.

As you move through the toolroom, making your way to the classroom for some instructional theory and strategy, walls are lined with photographs dating back to 2009, highlighting more than 1,700 industry peers who have completed training in this facility. Its an impressive wall of happy faces because they are now better armed to tackle the tooling challenges of each day. They now understand that if their shop is performing a lot of troubleshooting, they did not properly build their preventative maintenance (PM) processes.

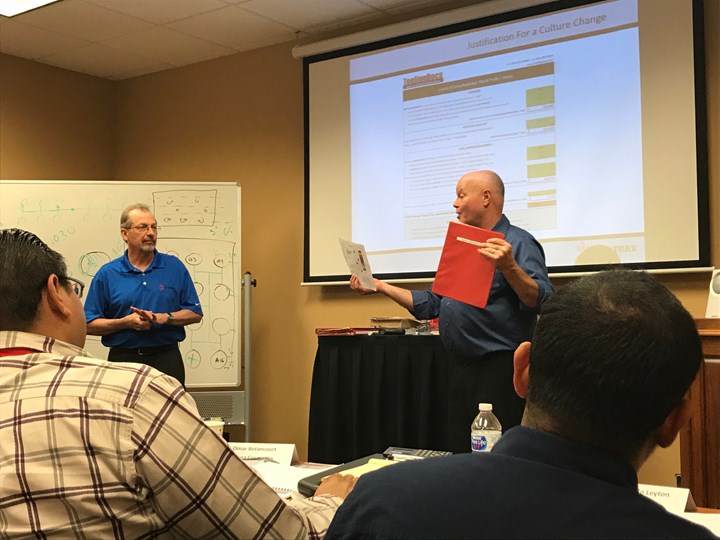

Training here is not new, but there was something special about this particular training session: the mix of content. This time, Steve Johnson, president, and Glenn Keith, global assessment and training manager at MoldTrax, set out to connect design, processing and maintenance because they believe and have discovered that cross-training across these disciplines can dramatically improve the troubleshooting skills of a mold designer, processing engineer and toolroom technician. And, the interest of trainees reflected this balance of design, processing and maintenance.

Specific objectives included mold cleaning, proper guidance for PM, PM scheduling, strategies for heading off problems, collecting data, prolonging gate inserts and broadening knowledge of tooling issues to improve mold designs. To make this “connected” training happen, Johnson partnered with Andy Routsis of Routsis Training, who added mold design and processing to the standard maintenance mix.

Workstations are furnished with top-of-the-line Gerstner toolboxes, computers running MoldTrax data management software and flat-screen TVs providing an up-close-and-personal look at various mold maintenance and troubleshooting best practices.

The Maintenance Process

“Mold repair is the second most expensive budgetary item in a plastics molding facility,” Routsis says. That statement should make everyone stop and pay attention. The only way to change that figure is to change the culture, and we all know that culture change is tough.

“We wish we could just have somebody purchase maintenance widgets that they could just stick in the mold to make things better. But it doesn’t work that way. It’s one little piece at a time,” Johnson says. “Begin with the process, start systemizing things and then people will begin to see it working and experience the payback, so then you can implement a little more and then a little more.”

Specific maintenance systems and process are necessary to end the firefighting culture of many toolrooms today. “We have a process that allows shops to efficiently produce quality parts on time. Without a process, you are freelancing how you do something, and then it is never done the same way,” Keith says.

The key to making maintenance a priority is justification through dollars. Before a toolroom team tries to make any changes in the maintenance environment, they need to figure out how to turn everything they do, plus all the issues, into money.

Johnson strongly believes in justification through dollars. He advises that before a toolroom tries to make any changes in the maintenance environment, they need to figure out how to turn everything they do, plus all the issues, into money. “That will get everyone’s attention because that’s the equalizer,” Johnson says.

The hallway walls are lined with photographs that date back to 2009, showcasing more than 1,700 industry peers who have completed mold maintenance training in this facility.

Let’s face it, every other aspect of plastics manufacturing has a process that employees must follow from scientific modeling to design guide checklists to simulations, but maintenance is an afterthought most of the time. “Maintenance is thrown in the back of the warehouse with a bench, some rags and a five-pound hammer working on a half-million-dollar piece of equipment. This is not the way it is supposed to be,” Johnson says.

This attitude makes this mold maintenance training program a culture shock to many attendees who range from mold repair technicians to processing engineers. “For so long, there’s been no accountability. It’s a free for all because they’ve been free to do whatever they want to do when they want to do it, and here we demand following the system every time,” Johnson says.

The Cost

What system, you ask? Well, there’s a lot to it, but it’s also a lot of common sense. For example, everybody has a horror story, like putting cavity blocks in upside-down, forgetting bolts or leaving things out. Then someone places the mold in the press, puts the bolts in and closes the press, causing 500 tons of pressure to crush $50,000 worth of tooling because they didn’t have the patience to slow down to see what the problem is. Yikes! The first thing to do is slow down or, as Johnson says, “Put down the hammer!”

Little mistakes can cost hundreds of thousands of dollars because people are in a hurry due to the manufacturing urgency that everyone feels. However, a toolroom needs to be accurate, safe and fast. It’s all about a tech’s focus level and his or her ability to work very carefully and measure before starting.

“Before you can grind and work in tenths, you need to measure in tenths, which takes a lot of feel and the right equipment. Sometimes, we have a loose connection between the hand and head. Critical areas need to be measured as you’re putting molds back together while you’re assembling the tool, especially when working on hot manifold systems,” Johnson says.

For example, for a technician to truly have command of a tool in his hand, whether it’s a hammer, pry bar, screwdriver, saw or even a precision micrometer, he must read the resistance, because when you are trying to measure something within two-tenths (a hair split 10 times) you have to have a delicate feel. “You cannot be heavy-handed. Your job is to understand the resistance and how much you should feel, and when it becomes too much, you have to put the tool down and find out where the resistance is coming from. The answer is not always more leverage,” Johnson says.

Steve Johnson, president, and Glenn Keith, global assessment and training manager for MoldTrax, teach an intimate room of “students” their process of mold maintenance, which enables shops to efficiently produce quality parts on time. Programming also includes a look at how connecting design, processing and maintenance disciplines can dramatically improve the troubleshooting skills of a mold designer, processing engineer and toolroom technician.

When I asked Johnson and Keith for their recommendations on what a toolroom should do first to get a maintenance process underway, they both said to clean up the shop and get organized, then work on standardizing the language to collect better data for improved documentation.

Maintenance is a process, so as a toolroom equates everything to a dollar, they must also do that within a process of documentation. However, historically that’s been very difficult to do because shops use data collection through maintenance stories that use ambiguous, non-standard terminology. “You’re never going to get any better if you can’t measure to justify what you do. You must standardize first,” Keith says. Here is where MoldTrax maintenance tracking software comes into play. Key software features include track performance metrics along with maintenance and tooling costs for a variety of molds and dies, drop-down menus built on a shop’s standard terminology for accurate reports, consistent instructions and images, and a custom troubleshooting guide to create a specific knowledge base for every mold.

Maintenance is a process, so as a toolroom equates everything to a dollar, they must also do that within a process of documentation.

The Workshop Takeaways

Theory and best practice instruction demonstrate the importance of choreographing mold bench work because proper mold maintenance is not freelance work; it is a process.

The method to this maintenance madness can be taught in a classroom setting all day long, but Johnson and Keith believe that until techs get their hands on a tool and struggle, they won’t retain it as much information. So, MoldTrax workshops involve both lecture and hands-on practice. “We want to get toolroom teams trained up, so you don’t need to call for help,” Keith says.

If you walk away with nothing else, both Johnson and Keith want toolroom technicians to understand the eight stages of systemized repair: PM preparation, disassembly, troubleshoot, correction action, clean, assembly, final check and stage/rack. Each of these stages can be broken down into 10 vital steps. For example, final check:

- Verify all available cavities are open and those unavailable are blocked.

- Verify current cavity identification numbers are correct.

- Check all air/water cooling circuits.

- Inspect electric test manifolds, heaters, probes and thermocouples.

- Check knockout rods and components for uniformity, length and condition.

- Complete repair sheet form and return to the mold maintenance office.

- Enter repair sheet data into the maintenance system.

- Tag and place salvageable tooling into appropriate rework bin.

- Track mold location and status.

- Stage mold in the appropriate location.

Each stage has its own setup steps to follow. To pique your interest in the other types of insights and instruction you experience through proper mold maintenance training, here are some of the workshop highlights.

Mold Design

- Plastic parts are getting more complex (more detail, functionality and specialized plastic materials). Simplify part design and use standardized mold components when possible to reduce costs and lead time.

- Gate location and gate type is the most important consideration for any injection mold.

- Use software to simulate the result of gate location and note what happens when you change gate type and location.

- More gates always result in more weld lines.

- If at all possible, use only one gate.

Processing

- Look at plastics through the eyes of a process engineer. Simplify the process and establish process outputs that correlate to an acceptable part.

- Ensure the best mold quote by presenting the moldmaker with a model of the part that you wish to produce. Identify critical features and dimensions so that the mold can be constructed to accommodate.

- Scientific molding is simply short shot molding — shifting from velocity to pressure when the mold is filled 90-95%.

- Match the outputs of the process to yield the same part every time. Perfect process outputs equal a repeatable part.

- Use a setup sheet and capture process outputs. Revise your existing setup sheet to include process outputs. This will ensure part consistency.

Venting

- You can never overvent an injection mold.

- Vent everywhere — sprue and runners, inserts, cores, ejector pins and blades, slides and lifters.

- Be certain that you are venting to atmosphere and relieve pass the seal-off area. Utilize the correct vent depth to avoid flash.

- Always check clamp tonnage. Determine when the part flashes by dropping tonnage. Once the part starts to flash, add 10% to accommodate process variation.

- With poor venting, the vents will begin to build up residue. In extreme cases when the entrapped gas cannot get out, you’ll experience dieseling (explosion).

Tonnage

- Determine minimum tonnage and add 10% for variation. This will maximize venting effectiveness.

- Measure tie bar stretch with family molds to see if it is even and to determine if tonnage is affecting the press/machine (not just the mold).

- Use dial indicator and measure the stretch of all four tie bars.

- Understand mold size and tonnage, or you will damage the toggle mechanism. The footprint of the mold is important. Too little and you will damage the platens. Too big and you may damage the toggle.

Maintenance

- Every mold has a weakness. Create a PM plan around that weakness.

- No more duct tape maintenance books or files of work orders. Today, proper mold maintenance requires software.

- Share knowledge to maintain repair and maintenance consistency

- Avoid under- or over-maintenance. PM mode is replacing things at a certain number when that number comes up. That’s good as long as that number is right.

- Following the eight stages of PM: preparation, disassembly, troubleshoot, corrective action, clean, assembly, final check and stage/rack.

- Follow the system. Cleaning is number five for a reason: You are wiping away all the clues, which will make it difficult to troubleshoot.

- Clean cooling channels.

- Chart mold wear to help create a PM plan.

- Performing a mold positional analysis to remedy runner imbalance (lineal versus rheological balance)

- Always look for wear defects.

- Identify the controlling features of each mold.

- Determine where your maintenance dollars are going.

- Collect data points at the press to identify root causes.

- Use data to convince someone in the corner office that you want to improve efficiency.

- Don’t use brass or aluminum hammers during assembly because they chip.

- Listen to your hot runner. Look for cable issues, loose pins/damaged cables, gate insert problems and incorrect flow.

- Check tip “l” heights (distance from the front of the manifold plate to the top of the tip) because short tips cause a temperature increase.

- Check hot tip systems as tips erode.

- Follow the proper startup and shutdown procedure (waiting for the hot runner to soak out; 30 minutes or so).

The Impact

Matt Lance is the assistant manager of plastics maintenance in tool and die for Toyota Motor Manufacturing in Georgetown, Kentucky. He recently moved to the tool and die side of the business, so this workshop was perfect timing to broaden his experience and knowledge of mold design, setups and various mold components. Lance is now armed to tackle documentation tracking, which he knows is key to helping the toolroom get out of firefighting mode.

MoldTrax Global Assessment and Training Manager Glenn Keith demonstrates an easy and effective method for doing a pressure check for water leaks. For this workshop, he also teams up with MoldTrax President Steve Johnson and Andy Routsis of Routsis Training to cover mold cleaning, proper guidance for PM, PM scheduling, strategies for heading off problems, collecting data, prolonging gate inserts and broadening knowledge of tooling issues to improve mold designs.

“My team calls itself a MASH unit, which is the opposite of what it should be,” Lance says. “After my first few months in this new role observing the team and now attending this workshop, I know that we don’t do a whole lot with documentation, so I need to find what we are doing and then implement some simple tracking methods to truly understand what’s going on and where we need to focus.”

Abraham Martinez has been with Albea Cosmetics in Brownsville, Texas, for 30 years and has been mold shop superintendent for the past 3 years. He brought the company’s manager, responsible for process and managing personnel and the mold shop supervisor, as well. “We want to learn to interact more effectively with the process guys in the shop to provide a cross-training experience when it comes to proper mold maintenance. I want to take what we are doing to the next level,” Martinez says.

For example, they do pressure checks for water leaks, but lack the equipment that Keith demonstrated in the shop, which provides an actual number to record.

Proper mold maintenance is not difficult, but it is an exercise in patience, professionalism, accountability and discipline to do the right thing without someone looking over your shoulder.

Kevin Rapant is a process engineer with MGS Manufacturing in Germantown, Wisconsin, and came to learn more about mold maintenance and to tie that together with processing. “Many times, tribal knowledge can limit learning, so programs like this provide alternate ways of doing things. For example, we can clean molds faster using dry ice, so we don’t have to pull molds as much, or to think before just jumping in and flashing tools. Stepping back and taking a second to think about things,” Rapant says.

Rapant also emphasized the value of getting up close and personal with technology for mold maintenance. “When you use something, you have more questions compared to just seeing technology. For example, after using the dry ice blaster, I can confidently suggest when we should use that approach instead of the team pulling the mold for the toolroom to tear it down,” Rampant says.

All curriculum and hands-on training continually reinforces the importance of developing a specific maintenance process to ending the prominent firefighting culture in toolrooms today.

Mexico-based Cubasa sent its director of engineering, Adalid Perez, and the first thing that he is going to do is “sign the P.O. for MoldTrax and sign more of my shop guys up for the ToolingDocs Certification levels one and two.” He’s also interested in ultrasonic cleaning because they have a lot of beryllium copper applications, and cooling lines are critical for their thin-wall fast-cycle molds.

Everyone I spoke with agreed that connecting face to face with peers, suppliers and instructors with material and tools in-hand in an intimate, intensive workshop setting provides a more effective way to learn about technology, and more importantly, enables you to share your problems and find solutions.

Whether you want to work on molds, manage molds or design molds, you need to understand how these systems work and what is necessary to take them apart to clean them up. Proper mold maintenance is not difficult, but it is an exercise in patience, professionalism, accountability and discipline to do the right thing without someone looking over your shoulder. “That is what separates the pounders and apprentices from the journeymen. It is that person who can do all that without constant supervision,” Johnson says.

Related Content

Considerations for Mold Base Material Selection

Choosing the right material can greatly affect the profitability and cost of your application.

Read MoreForces and Calculations Are Key to Sizing Core Pull Hydraulic Cylinders

To select the correct cylinder, consider both set and pull stroke positions and then calculate forces.

Read MoreTreatment and Disposal of Used Metalworking Fluids

With greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are “consumable” and have a finite life.

Read MoreSolving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

Read MoreRead Next

The State of Maintenance: Where Are You?

New products, equipment and software are beneficial to mold maintenance, but they do not change the fundamental way a repair technician performs the job if the culture remains reactive. Is your toolroom reactive or proactive?

Read MoreMaintenance Matters: Cultivating Craftsmanship

Toolroom managers need to help repair technicians become skilled mold troubleshooters and craftsmen rather than tooling replacers and cleaners.

Read MoreVIDEO: Full, Automatic Waterline Maintenance

Tyler Boss and Scott Smith of DME Company review the key components of comprehensive waterline channel maintenance.

Read More

.jpg;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)