Plastic Injection Molder Debuts EOAT, Mold Monitoring Solutions

NPE2024: Exhibiting for the first time, European-based Mouldpro ApS highlights new solutions — the Roborex and Flosense — alongside partner Globeius.

Denmark-based Mouldpro ApS is exhibiting for the first time with Globeius Inc., partner and exclusive North American distributor for Mouldpro. The company is a well-established supplier of products for plastic injection molding, hoping to bring European quality to the U.S. at competitive pricing.

In addition to showing visitors a wide range of general products and supplies for injection molding, recently introduced Mouldpro products and two new offerings are available to attendees.

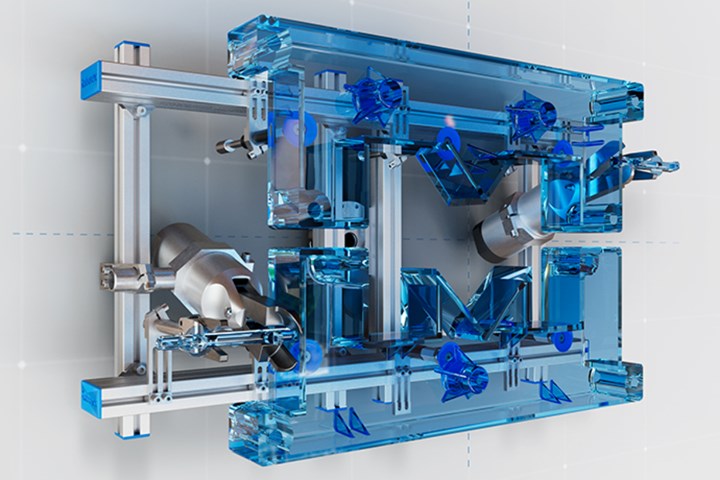

One innovation, Roborex, is making its debut at the show. The end-of-arm tooling (EOAT) helps streamline automation and increase productivity in the molding process.

Also making its debut is the Flosense thermal management/mold monitoring system. Flosense provides optimum control over mold cooling processes, reducing cycle times. It is both affordable and flexible, making it indispensable for those who desire to reduce costs while improving processing control and quality, according to Mouldpro. The system uses sensors to measure the differences in input and output temperatures (Delta T) and pressures (Delta P) as well as total flow rate through the system. It also alerts technicians in real time about the stability of the process and any potential issues, such as waterline blockages or leaks, heater or cooler malfunctions and so on. Many more features will be demonstrated at the booth.

Related Content

-

For PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

-

Corrosion-Resistant Mold Steel Designed For Polishability

NPE2024: Uddeholm showcases its Tyrax ESR mold steel that combines toughness, corrosion and wear resistance.

-

Educating the Next Generation of Plastics Professionals

These schools and local industry are working together to close the workforce gap in the plastics industry by offering hefty plastics curricula and training programs for degree-seeking students as well as current plastics employees looking to upskill.

.png;maxWidth=970;quality=90)

.jpg;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)