Latest Engineer News And Updates

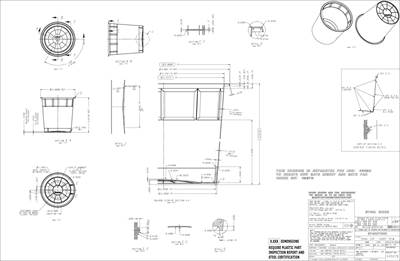

Mold Design Review: The Complete Checklist

Gerardo (Jerry) Miranda III, former global tooling manager for Oakley sunglasses, reshares his complete mold design checklist, an essential part of the product time and cost-to-market process.

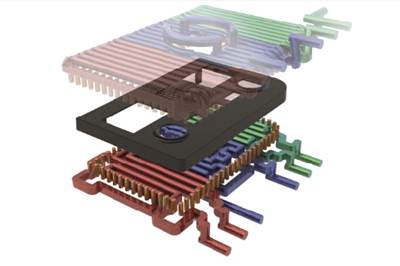

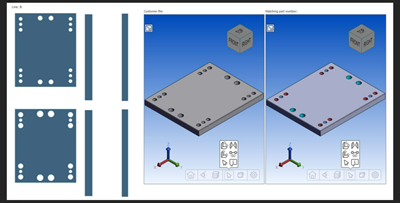

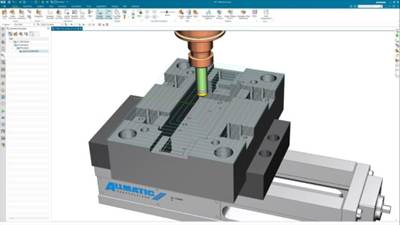

Read MoreHow to Customize an Interoperable Software Solution for Your Moldmaking Process

A connected software solution streamlines the moldmaking process by providing a unified source of design data, enhancing efficiency and reducing errors, with five key steps benefiting from this integration.

Read MoreVIDEO: Standardization and the Future of Moldmaking

Progressive Components President Glenn Starkey discusses their focus on standardization and the future of moldmaking (it’s here to stay!).

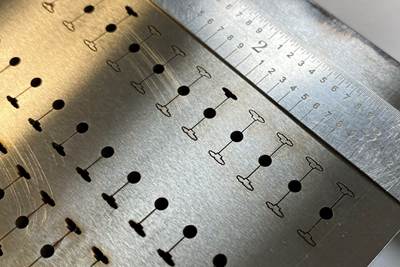

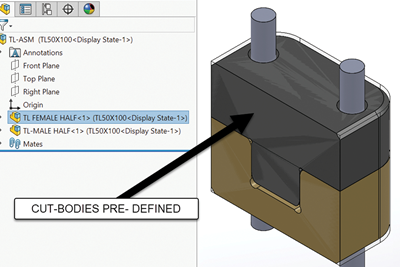

WatchSoftware Aids Localization of Injection Mold Inventory

NPE2024: Hasco introduces Mould Track for the precise tracking of injection mold inventory for improved production planning.

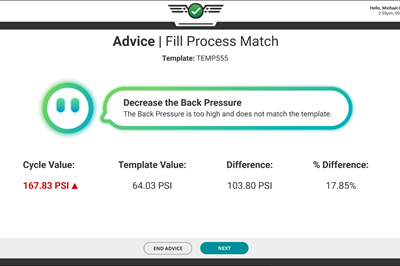

Read MoreSmart Assistant Bridges Injection Molding Skills Gap

NPE2024: MAX the Process Advisor, as well as free presentations and training by RJG Inc.

Read MoreFeatured Posts

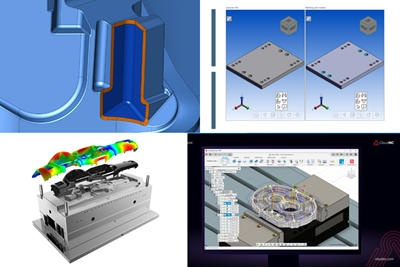

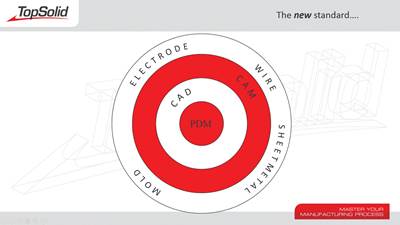

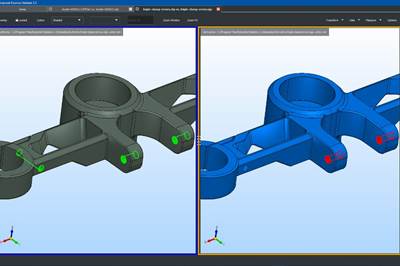

Design, Management Software Resources for Mold, Die Applications

As technology advances, so too do the options available to efficiently design molds or manage the data involved in their progress and production. Here’s a roundup of some of those solutions.

Read MoreNew Year, New Popular Articles from MoldMaking Technology

The top ten most-viewed articles in January reflected not only what our readers wanted to see—but also what is new and trending in moldmaking.

Read MoreManaging all That Data

Product data management may have a bad rap, but making it a priority rather than an afterthought can help make the most of your design and machining information.

WatchHow to Use and Protect Remote Machine Monitoring Data

Collecting, analyzing and securing machine data in real time can substantially improve productivity, profitability and customer satisfaction.

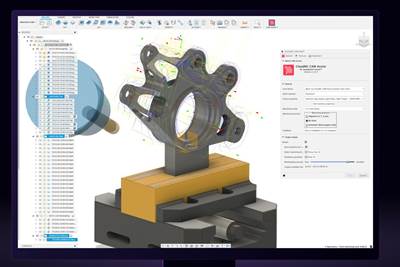

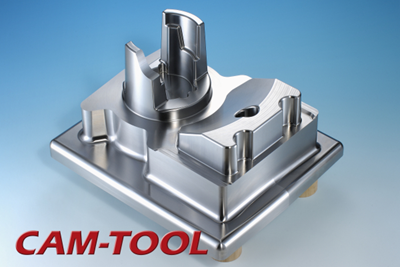

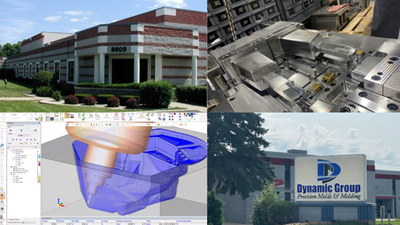

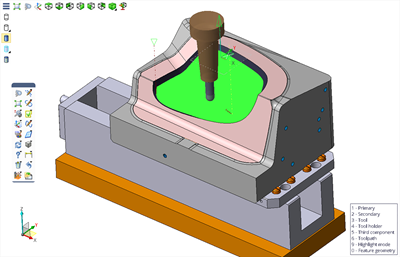

Read MoreCAD/CAM Software Reduces Delivery Times by 70% With a Six-Month ROI

Single integrated CAD/CAM package reduces translation errors, simplifies design process, improves shop efficiency and shortens tool lead times.

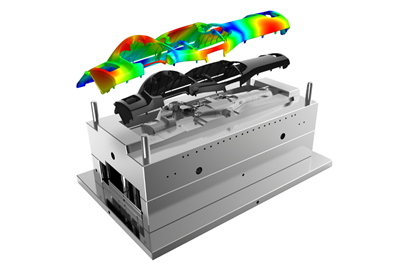

Read MoreHow to Use Simulation to Achieve a High-Gloss Surface Finish

Combining simulation, conformal cooling, and a rapid heat and cooling process can predict and produce the required surface finish for high-gloss plastic parts.

Read More

.png;maxWidth=300;quality=90)