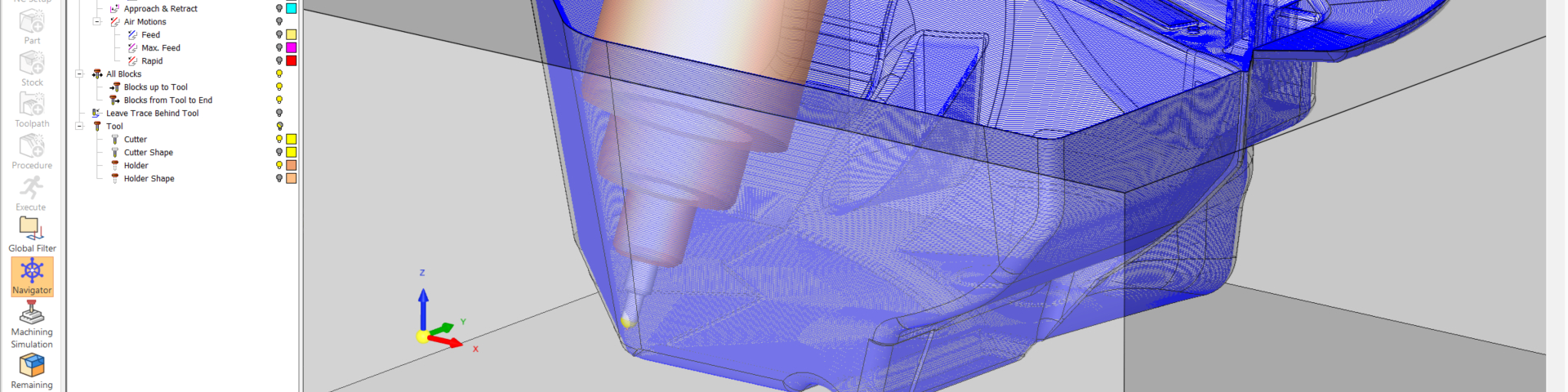

Moldmaking is important to Cimatron because it is the number-one focus of the team and its integrated CAD/CAM system. And it is celebrating 40 years! The company says its CAD/CAM was created with the moldmaker in mind. Here, Ralph Picklo, Director of Sales for Cimatron at CAMBRIO, shares what it means when CAD/CAM is created with the mold builder in mind compared to other CAD/CAM users.

He also shares his perspective on smart tooling, AI, Industry 4.0 and automation regarding their importance to moldmaking. Cimatron understands its value to this niche market because its CAD/CAM system enables the automatic generation of intelligent conformal cooling channels. Users can control and modify the automated results or design their channel quickly and easily.

Lastly, Ralph walks viewers through what the right CAD/CAM has to have for moldmakers to experience the benefits.

Watch the video interview above.

For more video content from MMT, visit our Videos page

Related Content

-

Leading Mold Manufacturers Share Best Practices for Improving Efficiency

Precise Tooling Solutions, X-Cell Tool and Mold, M&M Tool and Mold, Ameritech Die & Mold, and Cavalier Tool & Manufacturing, sit down for a fast-paced Q&A focused on strategies for improving efficiencies across their operations.

-

How to Manage Wall Thickness Changes in Your Mold Design

To ensure even filling and cooling, consider wall section transitions, corners and fillets, ribs and bosses, lip and rim designs and CAE flow simulation software.

-

MoldMaking Technology's Most-Viewed Content 2022: Products

MMT shares the five top-viewed technologies, equipment and services of 2022 in each Engineer, Build, Maintain and Manage tenet based on Google Analytics.

.jpg;maxWidth=300;quality=90)