A 46-year-old moldmaker and custom injection molder, Delta Mold Inc., operates two facilities that run 24/7 in Charlotte, North Carolina. The company is ISO 9001:2015 certified, has three offshore partnerships to handle overflow work and is the largest moldmaker in the southeast U.S. Source | Delta Mold Inc.

With 82 team members and two Charlotte, North Carolina, facilities totaling 70,000 square feet/6,503 square meters that run 24/7, Delta Mold Inc. is a 46-year-old moldmaker and custom injection molder with $25 million in annual revenue. The company builds injection and compression molds for 320 customers in the appliance, agricultural equipment, consumer electronics, food storage, ground transportation, HVAC, lawn and garden, plumbing, recreational equipment and storage and refuse segments. In a typical year, the company ships three molds/week.

However, given the diversity of its markets and the broad range of types and sizes of molds it produces, Delta Mold can build as many as 300 tools in a year or as few as 80, depending on size and complexity. In addition to compression and straight injection, the company also produces co-injection, core-back, gas-assist, counterpressure, structural foam, microcellular foaming and stack molds sized for presses ranging from 50 to 6,600 U.S. tons/45 to 5,987 metric tons.

Delta Mold produces between 80 and 300 molds/year for 320 customers across a variety of end markets. Source | Delta Mold Inc.

“As the primary mold builder in the southeast U.S., we work hard to stay diversified and agile, to understand the needs and requirements of our customers, and to be their go-to source of injection and compression molds,” Ernie Young, Delta Mold president, explains. “That means being competitive with mold builders in China producing $25,000 molds but also being able to produce 8,000-ton molds if needed. Our philosophy is to not turn away any good business from customers, whether it’s a mold with a good margin or one with a small margin. That way, we keep business in North America, we make sure our partnerships stay strong and we keep customers happy and with us for the long run.”

Young adds that the company has streamlined its internal processes to keep overhead as low as possible while providing customers with world-class molds at globally competitive pricing. “We’ve definitely invested in lots of automation and new equipment supported by the best software resources, plus we’ve trained our team members to machine as fast, accurately and efficiently as possible,” he continues. “The question we ask ourselves every week is ‘How do we become better at quality and delivery?’”

The Delta Mold team focuses attention on both individual components and the entire mold assembly during the engineering and manufacturing phases. They also give that kind of attention to purchasing each component that goes into their molds. “When you design to meet world-class quality and delivery targets, if you get the quality and delivery correct, then your price falls in line,” Young says.

Accurate, Actionable Information Faster

As part of its investment to streamline its financial processes, in 2017, Delta Mold decided to replace its legacy enterprise resource planning (ERP) system, which the company had outgrown. A team was assembled and spent the next year evaluating options. “Initially, we wanted to have a better process to track jobs and integrate that with accounting, so our forecasting was more accurate,” Young recalls. “However, as we dug deeper into the possibilities, we realized what we really wanted was a system that empowered our employees to do their jobs better.”

Eventually, targets were narrowed down to three companies, then to two, after which a light trial was conducted on both finalist packages to see how each performed on a job-to-job basis. One company outperformed everyone else that had been evaluated, even with very limited customization.

Young, a Metro Detroit native who spent the early part of his career working in finance and purchasing at several automotive suppliers, recalled working briefly with a company called Plex while at a previous position, so he asked Nathan Wisch, Delta Mold IT director, to add them to the list of companies being considered. Once Wisch reviewed Plex’s offering, he got very excited.

“However, as we dug deeper into the possibilities, we realized what we really wanted was a system that empowered our employees to do their jobs better.”

“We were immediately struck by the fact that this system was designed specifically for manufacturers by a company with a manufacturing background,” Wisch explains. “We were also impressed that although it’s described as an ERP system, Plex incorporated more than just IT, accounting, procurement and human resource management [HRM] capabilities. It also integrated the functions of a management execution system [MES], quality management system [QMS], customer relationship management [CRM] system and a security credential management system [SCMS].”

“Plex sounded like exactly what we’d been looking for because it would enable our employees to do their jobs better — whether in finance, estimating, sales, program management, HR, engineering or on the shop floor,” Young continues. “With such an integrated system, we’d be able to see every job we’d won, know exactly how it was being designed and manufactured, and how we were doing in terms of meeting cost and timing targets.”

Besides conducting manufacturing and tooling feasibility studies and designing, building and texturing molds, plus occasionally designing the parts to be produced in those molds, Delta’s team also offers reverse engineering, engineering changes, tool maintenance and repair, tool storage, program management, internal/external production services, plus product sampling and custom injection molding. Source | Delta Mold Inc.

Managing ComPlexity

Plex by Rockwell Automation Inc. began life in 1989 as a special IT project at a Detroit automotive supplier. In 1995, it was spun off as a standalone company called Plexus Systems, which later became Plex Systems Inc. By 2001, the company was offering Plexus Online, claimed to be the first Cloud-based (rather than client server-based) ERP platform and the first sold on a software as service (SAAS)/subscription basis. The system gained converts — first in automotive and then in an increasingly diverse range of industries — for its ease of implementation, use and maintenance (features not associated with most ERP systems) and its ability to provide a broad range of features considered critical to manufacturers.

Since 2018, Delta Mold has relied on the Cloud-native, integrated Plex ERP platform from Rockwell Automation Inc. to manage nearly every aspect of the company’s business, from sales and estimating to supply chain management. Source | Plex Systems Inc.

“From inception, Plex was designed to incorporate a full suite of functions necessary to run a manufacturing business and that’s historically been a key differentiator and competitive advantage,” Chris Balow, Plex director of product management for discrete industries, explains. “If you consider its roots in the automotive industry of the 1990s and the challenges OEMs and suppliers at that time faced in serializing individual units of inventory and tracking them through the entire manufacturing process in case there was an automotive recall, there was just no system out there that controlled and maintained business processes, and nothing that tied past ERP to MES and quality and brought them together in one system. Our founders looked at that situation and decided they were smart enough to build a system that did offer that functionality and they were incredibly successful at doing so.”

Over time, the system evolved to include a full suite of functions that covered every aspect of a manufacturing business: ERP, HRM, MES, QMS, SCMS, CRM, inventory, shipping, supply chain management and later, rigorous traceability and food safety requirements. In 2021, Plex Systems was purchased by Rockwell Automation, a large industrial automation and digital transformation company and the only company globally positioned to offer the entire ANSI/ISA-95 model of enterprise and control systems in a manufacturing environment — from switches, sensors and controllers on machines all the way to the business management software that runs a company. At the time of the purchase, Plex ERP reportedly had more than 700 customers globally and managed 8 billion transactions/day.

“At the end of the job, we review what we did good and what we did bad, and that helps us do more good and less bad the next time. It’s such a powerful tool.”

While Plex historically included a full suite of functionality needed by manufacturers, and competitive ERP systems have slowly been following suit and adding more functionality to their packages in response to customer requests, the Plex team has changed direction. “As people have gotten more comfortable with Cloud services and SAAS, they would come to us and say things like, ‘We already have an ERP system, but it’s horrible at MES’ or ‘We love Plex’s production tracking and monitoring capabilities, so can we just purchase that specific module?’” adds Balow, who says that the company has worked to decouple and modularize key blocks of Plex to offer standalone ERP, MES or QMS. Another new feature is applying machine learning algorithms to help manufacturers do predictive (rather than preventative) maintenance.

Greater Productivity

Plex was installed at Delta Mold during Q2 2018 and proved far more powerful and useful than the team initially expected for both its moldmaking and molding operations. The system quickly provided team members throughout the company with highly usable data and analytics, helping management to tighten up financials and forecasting. Plex is designed to be highly customizable during setup (with 20,000-30,000 options/module), which helped it better meet Delta’s needs. For example, since different employees in different departments preferred data in different forms, Plex worked with Delta to customize reports so each user received the data they needed in the form they preferred.

Most tools are P20, 4140 or stainless, although occasionally Delta Mold produces something in aluminum alloys. Given the broad range of markets the company serves, injection molds can be very simple to highly complex — from single to 16 cavities — with or without side action. Source | Delta Mold Inc.

Every morning the whole team sits down, pulls up Plex and walks through individual jobs for the day. For instance, if they have a multi-tool package going through the shop, Plex enables them to track the target and actual internal deliveries in terms of time and labor for every component and every mold in that package in real time and indicates whether each aspect of the job is ahead of or behind schedule.

“Recently, we designed and built four molds for a consumer product,” Caitlin Gieza, Delta Mold finance manager, adds. “We were able to track labor in real time, monitor all purchasing of components, forecast remaining spend and track to the final delivery date.”

“Plex is easy to understand, easy to train and the data we pull from it every day helps us do our jobs better,” Wisch adds. “It even helps with ISO 9001 audits. We pull up Plex and show the auditor how we validate the quality of each component we machine. We’ve got all our documentation in one place. That digital thread gives us full traceability and transparency and it can travel with a tool throughout its life. Plex has proven phenomenal for a business like ours. We couldn’t have asked for anything more from the system. Plex doesn’t just supply us, they also support us.”

“With such an integrated system, we’d be able to see every job we’d won, know exactly how it was being designed and manufactured, and how we were doing in terms of meeting cost and timing targets.”

“The scheduling function is simple and phenomenal,” Young continues. “It lets us look at a specific job on a specific machine with a specific machinist and determine if the job can be done in the amount of time we’re estimating. We’re looking at data in real time on how each component of the job, plus the entire project, is doing in terms of time and labor. We’re also tracking OEE [overall equipment effectiveness]. There’s no doubt it enables us to run more unattended hours and achieve more uptime. It also enables us to achieve greater than 98% productive labor hours and to boost mold delivery times to 100% and raw material delivery times to greater than 95%. At the end of the job, we review what we did good and what we did bad, and that helps us do more good and less bad the next time. It’s such a powerful tool.”

Related Content

Laser Welder Yields Fast, Precise Mold Repair

Intralox's integration of the Alpha Laser ALFlak has significantly improved its toolroom efficiency when it comes to difficult welds and urgent repairs.

Read MoreHot Runner, Mold Component Partnerships Lead to Innovative Mold Designs

Formula Plastics takes on tooling via sister company Formula Tooling using dedicated partners, 3D modeling services and highly trained engineers to develop advanced mold designs.

Read MoreHow to Clean and Maintain Molds With Intricate Conformal Cooling Channels

A water-based, eco-friendly plastic mold cleaning system helps Rankine-Hinman Manufacturing restore flow rates and avoid big-ticket failures on complex and costly molds.

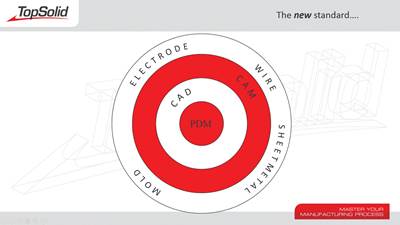

Read MoreCAD/CAM Software Reduces Delivery Times by 70% With a Six-Month ROI

Single integrated CAD/CAM package reduces translation errors, simplifies design process, improves shop efficiency and shortens tool lead times.

Read MoreRead Next

MMT Chats: The Science of Moldmaking, Part 1

MoldMaking Technology Editorial Director Christina Fuges chats with Don Smith, North American Senior Tooling Engineer for Scholle IPN in Northlake, Illinois about the future and science of moldmaking.

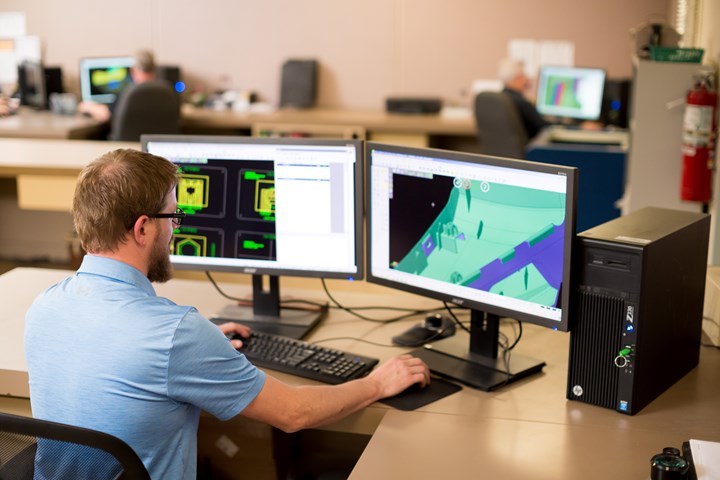

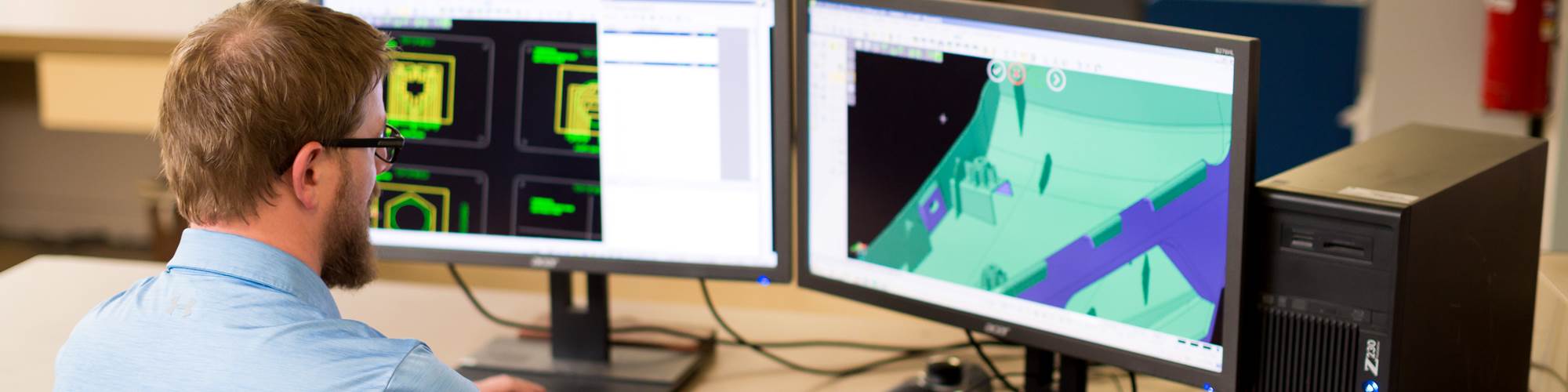

Read MoreDesign Strategy Tackles Big and Small Complexity Challenges for Southeastern Mold Builder

Delta Mold Inc.’s core values, engineering expertise, five-axis machines and molding capabilities help the team turn a proposal into a manufactured mold or part with custom design, finishing and assembly.

Read MoreManaging all That Data

Product data management may have a bad rap, but making it a priority rather than an afterthought can help make the most of your design and machining information.

Read More

.jpg;width=70;height=70;mode=crop)