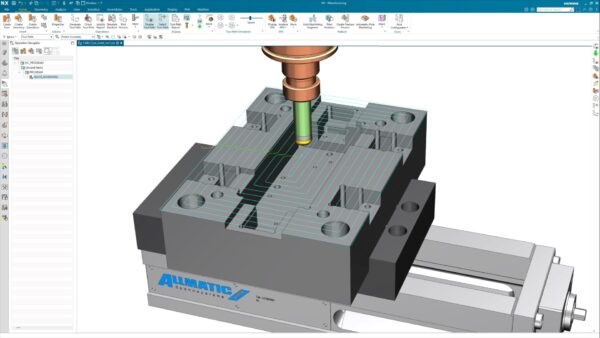

CAM Programming Efficiencies Streamline Mold Operations

Siemens has released updates to its NX Software, including new and streamlined features for NX CAM, applicable to moldmaking.

Photo Credit: Siemens Digital Industries Software

Siemens Digital Industries Software announces some update releases to its NX software for manufacturing for enhanced production. While this announcement covers NX CAM in particular, Siemens also offers updates for NX Additive Manufacturing , NX CAM On-Machine Probing, NX CMM Inspection Programming, Part Manufacturing Data Management, NX Line Designer and Fixture Planner, and NX Assembly Line Planner.

The new Quick Roughing operation in NX CAM software offers a swift and easy-to-program offset roughing process with a user-friendly interface, streamlining the creation of roughing operations. It is ideal for programming simpler components, such as prismatic parts and less complex molds, cavities and cores, dies, castings and forgings with contoured shapes using planar cut levels.

A Face Milling operation provides modern programming techniques to interactively adjust toolpath parameters, improving programming efficiency. Face Milling operations have been significantly improved. The features, offering zig and zig-zag patterns, now make it easier for users to program face milling toolpaths. The interactive on-screen UI allows users to easily specify path parameters, providing them with automatic toolpath previews and ensuring faster toolpath generation.

The latest Wall Finish Barrel Swarf operation helps reduce machining time and improve surface finish using advanced settings to generate optimized toolpaths easily. Users can now use taper barrels for parts with straight walls and tangent barrels for parts with curved walls.

The user-friendly and enhanced Holemaking features now make it easy to manage control points during drilling and pilot drilling, especially when working with depths less than the in-process workpiece (IPW) stock. The new control point option called “use initial” ensures the tool consistently positions itself above the initial programmed workpiece (IPW) for each operation, preventing sudden movements into the previously drilled hole.

With the upgraded Cloud Connect Tool Manager, generating entire tool assemblies using the assembly tool preview is possible, supporting several search functions for added convenience.

A complete look at NX software updates can be viewed here.

Related Content

-

How to Manage Wall Thickness Changes in Your Mold Design

To ensure even filling and cooling, consider wall section transitions, corners and fillets, ribs and bosses, lip and rim designs and CAE flow simulation software.

-

The In's and Out's of Ballbar Calibration

This machine tool diagnostic device allows the detection of errors noticeable only while machine tools are in motion.

-

Products and Services for Multiple Moldmaking Needs

New year, new technology roundup! Featured here is a collection of product offerings, from profile milling cutters to industry-specific CAD/CAM software to innovative hot work tool steels.