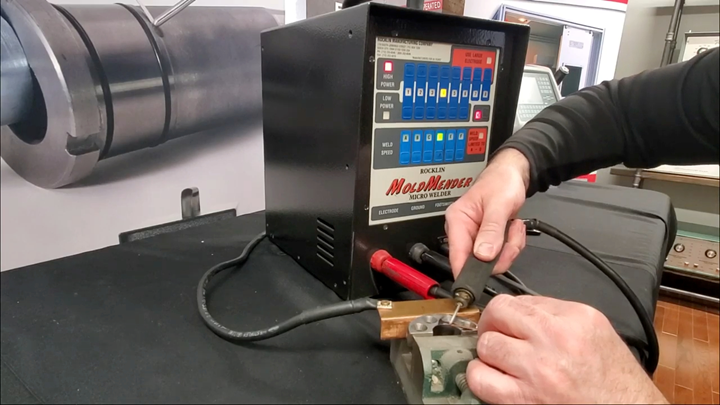

Portable Low-Heat, Non-Arcing Resistance Welder for Mold Repair

Rocklin’s user-friendly MoldMender Micro Welder delivers simple and cost-effective localized repair in-house with precision and versatility, enhancing mold and die durability and reducing disassembly and downtime.

MoldMender edge buildup. Photo Credit: Rocklin Manufacturing Co.

Rocklin Manufacturing Co.’s MoldMender Micro Welder is a compact, handheld device that delivers simple and cost-effective mold and die repair in-house through a low heat, non-arcing welding process, ensuring controlled, localized repairs. Instead of sending molds out for repair or scrapping them prematurely, and dealing with disassembly or lengthy downtime, the MoldMender solves scratches, pin holes, parting lines flashing, and other mold and die imperfections with no welding experience necessary, addressing issues directly at the press.

Mold and die repairs are accomplished by producing interlinking spot welds to totally bond the repair material to the desired area of the workpiece. A simple process of rolling the electrode while triggering a footswitch permanently bonds the repair material, resulting in a consistent, quality weld with very little heat. This eliminates the need for a gas or welding helmet, while preventing excessive heat-affected zones and minimizing the risk of damage to surrounding areas. Further, minimizing the heat on the repair area enables welding without shrink lines, distortion or splatter on adjacent areas, which can often occur with other welding processes.

The ribbon, wire, paste, or powder repair material used is the same or similar material as the workpiece, producing a fully hardened repair ready for finishing. Since the amount and location of the repair material can be precisely controlled by machine setting, the slight finishing that is required can easily be performed with any standard methods such as EDM’ing, grinding, machining, plating, polishing, etc.

The MoldMender is versatile, enabling repairs on a wide range of steel materials, such as H13, P20, S7, stainless steel and more. Its resistance welding process also create strong, durable welds that enhance the lifespan of the mold, reducing the frequency of replacements and associated costs.

Related Content

-

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

-

5 Hot Runner Tips for Moldmakers and Molders

Best practices for initial hot runner tryouts and effective preventive maintenance.

-

Products and Services for Multiple Moldmaking Needs

New year, new technology roundup! Featured here is a collection of product offerings, from profile milling cutters to industry-specific CAD/CAM software to innovative hot work tool steels.

.jpg;maxWidth=300;quality=90)