Hot runner controller and molding machine integration is a big topic right now and tooling managers are taking notice because a lot of companies are trying to use the molding machine hot runner controls to run tools that are too big for the number of zones available on the molding machine. Using some control from the molding machine and the rest from a stand-alone controller can be disastrous (leaking tools, steel expansion wear, burnt and spitting material, unnecessary peak amp draws, uncontained scrap, operator confusion and inefficiency).

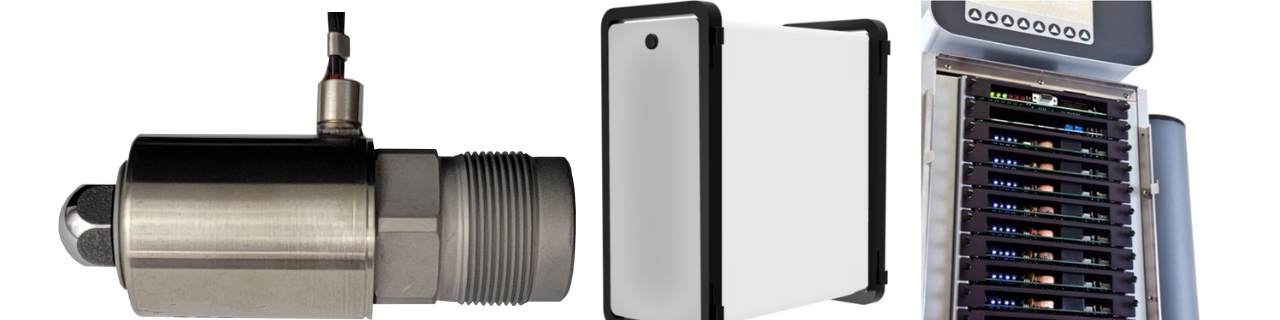

Here Chad Root Managing Partner for Fast Heat by Spark Industries breaks down a few molding machine integration concepts that protect hot runner systems, the molding machine, reduce scrap and help keep a log of events.

For more video content from MMT, visit

https://www.moldmakingtechnology.com/videos

Related Content

-

Predictive Manufacturing Moves Mold Builder into Advanced Medical Component Manufacturing

From a hot rod hobby, medical molds and shop performance to technology extremes, key relationships and a growth strategy, it’s obvious details matter at Eden Tool.

-

Precision Welding Services Offer Rapid Turnaround Mold Repair and Reduced Molder Downtime

X-Cell Tool & Mold relies on outsourced, high-quality welding repairs from Lewis-Bawol Welding to ensure its customers' molds are back in production quickly and affordably.

-

Surface Finish: Understanding Mold Surface Lingo

The correlation between the units of measure used to define mold surfaces is a commonly raised question. This article will lay these units of measure side by side in a conversion format so that companies can confidently understand with what they are dealing.

.png;maxWidth=970;quality=90)