Updated Control, Cooling Water Distribution, Electromechanical Ejector and Injection

NPE2024: Boy’s U.S. subsidiary marks its 50th anniversary in Orlando with six machines and U.S. intros for the Procan ALPHA 6 control, and hybrid ejectors and injection units.

Boy Machines Inc. (BMI), the sister company of the German machine manufacturer Dr. Boy GmbH & Co. KG, is marking its 50th anniversary at NPE2024.

Boy is bringing some developments it has previously showcased in Germany at the K and Fakuma shows. New to North America is the Procan Alpha 6 control system, featuring a 16:9 screen format, which will gradually replace current Procan Alpha 4.

Boy also highlights its new cooling water distribution system, which it developed in-house, and will become standard on its machines in the future. Here, cooling water is tracked via digital flow metering. With this system, the set flow rate and return water temperature is digitally monitored, recorded and displayed on the machine’s controller.

New to the North American market is an electromechanical ejector, enabling eject motion independent of hydraulics. The electromechanical variant offers two operating modes; movement can be coupled with Boy Handling LR5 gripper hand, or it can be synchronized with the opening stroke of the mold when used without handling. This ensures molded parts are comfortably extracted from the mold.

Boy also offers a hybrid or electromechanical injection unit that can enable simultaneous operation without the use of a double pump. The servo motor drive for injection and retraction of the screw operates independently of the machine’s hydraulics. This is particularly beneficial for short cycle times and high dosing quantities.

An electromechanical drive option for the injection unit enables injection and metering movements to be powerd by two servomotors. Force-measuring technology helps maintain switching points of the injection process to within a tolerance of ±0.01 mm. Source | Boy Machines

Boy is also introducing a manufacturing cell based on its LR5. Here, a Boy 35E-VV overmolding machine featuring an additional input terminal, the LR5 handling device and another assembly automation will overmold metal inserts into T-shaped handles. These will be removed from the mold by the LR5, and fed to an assembly automation, where four tool bits are individually selected by booth visitors for insertion into the plastic handle. The assembled multitool is then placed by the LR5 onto a conveyor to deliver the attendee a self-configured set of tools.

Boy also demonstrates its operational data acquisition (ODA) system. ODA with EUROMAP 77/87 acts as the interface between the injection molding machine and the manufacturing execution system (MES), covering production planning, quality control and operating cost tracking. The ODA system software from ProSeS BDE accesses the press’s Procan ALPHA 6 control. With this feature, machine settings, operating parameters and production data such as injection volume, melt temperatures and pressures can be captured and analyzed. The ProSeS software gives users the ability to access a Boy machine from anywhere, around the clock.

The machines on display represent a sampling of Boy’s entire product range. A new Boy XS E with servo drive and Procan Alpha 6 control will mold LSR bottle caps in cooperation with Nexus Elastomer Systems metering, a KIPE Molds tool and silicone material from Shin-Etsu. A Boy 35E-VV with a sliding table displays tool loading during process downtimes, and another Boy 35E-VV shows an automation cell in connection with an insert molding application, producing the aforementioned T-handle tool giveaway with customizable bits. A Boy 60E hybrid with electromechanical drive units for injection, dosing and ejection will mold closure caps for reusable lids that are produced in parallel on a Boy 125E. Finally, a Boy 125E, the company’s largest machine with an installation area of only 56 ft2, will produce reusable lids in an ongoing operation.

Related Content

For PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

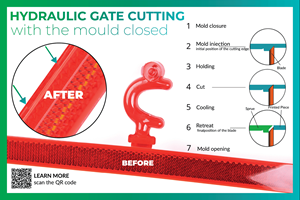

Read MoreHydraulic Gating Cutting Reliably Separates Molded Parts

NPE2024: Material displacement technology offered by Ermanno Balzi Srl enables precise separation of the molded part from the gate during the molding cycle.

Read MoreIntegrated Molding Solutions Provider Features Mold Demos, IML Systems

NPE2024: Global moldmaker StackTeck Systems demonstrates a new approach to producing an ultra-thin, clear container made with 100% PET resin, mold and automation system innovations and more.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreRead Next

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreBoy Machines’ BOY 100 E Injection Molding Machine Ensures Lower Energy Demand

Requiring less energy consumption for the production of plastic parts, Amerimold exhibitor Boy Machine’s servo-driven BOY 100 E improves cost-benefit and reduces ecological footprint.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

.png;maxWidth=300;quality=90)