Industrial Molds

5175 27th Ave.

Rockford, IL 61109 US

815-397-2971

customer.service@industrialmolds.com

industrialmolds.com

IS THIS YOUR COMPANY?

As Seen On MoldMaking Technology

Industrial Molds Supplies the Following Products

- Injection Molds

- Mold Maintenance & Repair Services

- Mold Tryout/Sampling Services

- Prototyping Services

- Sampling/Mold Tryout Services

Editorial, News, and Products

-

MMT Chats: Ingenuity in Action: Industrial Molds' Engineers Redefine Moldmaking

Industrial Molds’ engineering team showcases ingenuity and precision through complex DFM challenges, delivering optimized tooling, adaptability and customer-driven solutions.

-

How Industrial Molds Conquered a Complex Impeller Fan Mold Challenge

Expert engineering team overcomes complex impeller fan mold challenges through innovation, precision and collaborative problem-solving.

-

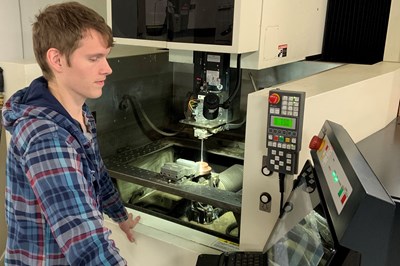

How Industrial Molds Improved Precision Manufacturing with Smart Automation

For over 50 years, Industrial Molds in Rockford, Illinois, has been building precision tooling. In 2005, the company adopted a new approach to remain competitive in high-mix, low-volume manufacturing.

-

30 Under 30: The Next Generation Reshaping Moldmaking

Young professionals are bringing new perspectives, technical skills and strong commitment to the moldmaking industry. MoldMaking Technology recognizes these individuals through our 30 Under 30 program, highlighting emerging talent helping to shape the future of precision manufacturing.

-

How to Successfully Reshore Tooling

Sloan Valve and Pyramid Molding Group shed light on the dynamics and challenges surrounding the shift toward domestic mold sourcing and the advantages of collaborating with a U.S. supplier to bring tooling back stateside.

-

Pyramid Molding Group Expands Workforce to Fuel Anticipated Growth

Twenty one additional team members since May 2023 broadens the company’s production and project capacity as a moldmaker and plastic injection molder.

-

Technology and Sourcing Guide 2023: Mold Builders

A variety of processes are used to engineer, build, maintain, repair and manage a mold, which can be offered as standalone services to be contracted to complete a mold build. Access this exclusive, online-only content, including a suppliers list and mold building services.

-

30 Under 30 Honors Program: Mentoring in the Next-Generation of Moldmaking Professionals

Young professionals are vital to the moldmaking industry, and it is important to acknowledge those making strides in shaping the industry's future. MoldMaking Technology recognizes the industry's young talent through its 30 Under 30 Honors Program.

-

Pyramid Plastics Installs Three New Industry 4.0 Injection Molding Machines

Injection molder to invest $2 million in new equipment and capabilities in 2022 to expand smart technologies, better monitor processes and data, and offer larger molding capabilities to customers.

-

MoldMaking Technology's Top-Viewed Content 2021: Profiles

The MoldMaking Technology team has compiled a list of some of the top-viewed profiles this year featuring Mold-Tech, Industrial Molds, Action Mold & Machining, A1 Tool Corp. and Innovation Mold & Design.

-

MMT Chats: 5 in 5 with Industrial Molds

This quick 5 in 5 MMT Chats video series reveals five best practices in five minutes on ways to improve efficiencies with technology, workforce development and business management. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

-

MMT Chats: 30 Under 30 Honoree, Mold Designer Says Key to Growth Is Harvesting Knowledge

MoldMaking Technology Editorial Director Christina Fuges invites Mold Designer Sasha Stojanovic of the Industrial Molds Division of Pyramid Molding Group as a guest on this MMT Chat. He shares his magnum opus and take on mentoring, as well as explains the challenge of machinability and why education must change. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

-

Mold Builder’s Automated 24/7 Unattended Machining Speeds Up Simple to Complex Mold Builds

Industrial Molds, a division of Pyramid Molding Group specialize in designing, engineering and special machining to create quality, precision tooling.

-

The Lean Dream Team: How to Achieve High-Cavitation, Critical Dimension Molds

Incorporating multiple automation technologies enables Industrial Molds to produce and repair highly complex, precision molds with a very lean team.

-

MMT Chats: The Merging, Marketing and Manpower of a Moldmaking/Molding Company

For this MMT Chat, my guest is Andy Peterson CEO of Pyramid Molding Group (Industrial Molds and Pyramid Plastics) in Rockford, Illinois, who shares his take on the strengths of bringing a mold shop and molding facility together under one group.

-

Shared Engineering Expertise Overcomes Design and Delivery Challenges

Collaboration on part and mold design between a molder and mold builder were vital to overcoming design and production challenges for a unique automotive project.

-

2020 Sourcing & Technology Guide: Service Providers

MoldMaking Technology’s annual Technology Review and Sourcing Guide is a comprehensive guide for researching today’s technology, equipment, products and services. Introducing a brand new section this year: Service Providers.

-

The AMBA Chicago Chapter Recognizes Top Apprentices

At its December 4, 2018 Chapter Meeting, the AMBA Chicago Chapter recognized seven apprentices whose employers nominated them for the annual Mold Your Career Award.

-

Scenes from Amerimold 2018 in Novi, Michigan

From technology demos and tech talks to awards and arcade games, Amerimold had much to offer industry this year.

-

2018 Technology Review and Sourcing Guide: EDM

MoldMaking Technology’s annual Technology Review and Sourcing Guide is an accurate, comprehensive, easy-to-read and easy-to-use use guide for researching today’s technology, equipment, products and services. The year’s latest moldmaking product developments within mold engineering/design, build and maintenance/repair are broken down into 10 sections, including EDM.

-

Industrial Molds Celebrates 50 Years in Business in 2018

Founded in 1968 by Jack Peterson, the company has enjoyed continued growth and success. Today, the Peterson family has three generations involved in the business.

-

Past LLA Winners Celebrate 15 Years of Moldmaking Excellence

Winning MoldMaking Technology’s Leadtime Leader Award helped these shops realize their strengths and recognize their weaknesses.

-

Moldmaker Adds Automated CNC and EDM Capacity

Industrial Molds Group specializes in engineering molds for medical, packaging, industrial, consumer and automotive markets.

-

Technology Tuesday: Automation Fuels Productivity

Cruise through this week’s Technology Tuesday blog to see ways in which automation is boosting productivity and efficiency in moldmaking.

-

For Moldmakers, Auto Industry Forecast Means Diversification is Key

Diversification seems to be the key for many shops that count automotive as a market focus.

-

Fun Friday: The Moldmaking Community Shows Patriotism, Heart and More

On September 15, 2017 our team at Alliance Specialties and Laser Sales partnered with our friends Tim and Kim Bartz from iWarriors and Mold Craft to host the inaugural Alliance iWarriors Charity Golf Outing.

-

Three Takeaways from Die/Mold Expo

What do you gain by attending events like the Makino Die/Mold Expo that was held last week at the company’s Technology Center in Auburn Hills, Michigan? I asked a few of the moldmakers I met there to share their personal takeaways.

-

Invest Now in Die/Mold Automation to Meet Growing Customer Demand

In today’s highly competitive global marketplace, there are two types of mold shop owners, (1) those who invest in new technology and automation to create innovative ways to meet customer demands for shorter lead times, more complex designs and tighter tolerances and (2) those show don’t invest and quickly fall behind other North American shops and low-cost, offshore manufacturers. Here is a case study from Makino about one mold builder who fits nicely into type number one.

-

What’s Your ‘Secret Ingredient?’

Given all the mold manufacturing companies I’ve visited or learned about, one detail continues to ring true with all of them: That “secret ingredient” to building a top-quality mold.

-

Powerful Production

Automated cells with RFID technology facilitate a “productionized” approach that helps this shop make molds more accurately and efficiently.

-

Creating Culture

Cultivating a team environment lightens the load on the individual person and distributes it among many, enabling faster lead times and better-quality products.

-

Pumping Up Molding Plans

Over at Pyramid Plastics, the custom injection molding business of Industrial Molds Group, plans call for purchasing 10 new Toshiba injection molding machines at the rate of one machine per quarter over the next two years.

-

Transition to In-House Welding

Bringing laser welding in-house can help mold shops reduce shipping and handling costs while improving mold quality, lead time and overall customer service.

-

Bottlenecks Determine Machine Purchases

A lot of planning went into the decision Industrial Molds Group made when purchasing new machine technology and renovating its existing building. Better work flow to help maintain good scheduling to meet lead times was a primary goal, and making the right machine purchases helped them attack production bottlenecks.

-

Collaboration Makes the Impossible Possible

For Industrial Molds Group, successfully completing a complex 2×2, two-shot family mold demanded a level of collaboration similar to that required by a symphony orchestra. A leading manufacturer of power tools was under severe pressure to begin production for a new product that had to be on store shelves by Memorial Day or the customer (a major retailer) would cancel orders for the entire year.

-

Close Relationship with Molder Pays Dividends

Industrial Molds Group

-

Implementing Automation

The first two shops I’ve visited as an editor for MoldMaking Technology have made major strides in implementing automation. They’ve also expanded their range of capabilities to cover more than just tooling.

-

A “Run for the Border” Expands Transportation Market Niche

“This opportunity demonstrates how a great relationship can develop into a partnership with customers, as we’ve become very much a value-added supplier to them. We’re co-located with them and that strategy lends itself to other OEMs looking for similar relationships.”

-

CNC Software Delivers 50-Percent Leadtime Reduction for Complex Molds

Industrial Molds considers Delcam’s PowerMILL CNC programming software to be critical to achieving its 8-week average leadtimes.

-

Industrial Molds Makes a Splash at amerimold 2012

Industrial Molds Group—the 2012 MoldMaking Technology magazine Leadtime Leader 2012 winner—reaped the benefits of exhibiting at amerimold.

-

2012 Leadtime Leader Awards: Industrial Molds Group

Extensive investment in equipment, technology and its employees coupled with an innovative approach to its mold manufacturing process has earned this mold manufacturer the MoldMaking Technology 2012 Leadtime Leader Award.

-

2012 Leadtime Leader Award Winners Announced at amerimold

In the Awards tenth year, we honor two outstanding mold manufacturers.

-

Complex Moldmaking Showcased at NPE2012

During NPE2012 a part from MPC, Inc.--a Tier 1 molder of automotive components--for which Industrial Molds Group of Rockford, IL, designed and built the mold won the "Single Part Award" in SPI's International Plastics Design Competition.

-

Customer Collaboration Yields Better Product, Reduced Costs and Plastics Innovation

The Water Outlet assembly is made possible through the development of a complex injection mold, incorporating multiple sequential valve gates to prevent material over-pack and gas entrapment.

-

Greeting From NPE2012!

Seems like one of the happiest places on the earth this week as Sherry and I walk the show floor at NPE2012 Orlando, FL. Early reports note that this year's event has surpassed earlier NPEs in scope and diversity, with a new venue, make-up, events and first-time participants.