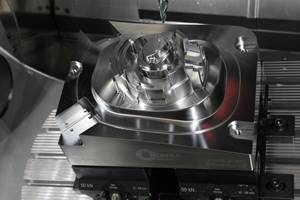

Industrial Molds designs and builds molds for thermoplastics, thermoset, die-cast and insert precision applications for automotive, appliance, electronics, caps and closures, medical, recreational and lawn and garden markets. Photo Credit: Pyramid Molding Group

Can you explain the value of a mold builder/molder partnership to your customers?

KD Shah, Industrial Engineer at Pyramid Plastics: We achieve mold design, build and sampling in record time because of the strong team approach between Industrial and Pyramid. The holistic approach across tooling, molding and equipment technology is beneficial to our company success, but also creates value for our customers. Lines of communication are open and transparent between our organization and with our customers.

Having the facilities and expertise to both design and manufacture molds, and produce the parts is key to Pyramid Molding Group’s success.

Our account managers are the primary contact with each customer and work collectively over both Industrial and Pyramid. They oversee each project from concept to completion. We believe the most significant results and best value occur when we design and manufacture the tooling and produce the parts. There are fewer chances for molding and production mishaps when a single source builds the tool.

This precision mold manufacturer specializes in multishot, injection mold, insert molds die-cast, gas assist and large tools up to 1,500 tons.

Is there a recent project that put Pyramid Molding Group to the test?

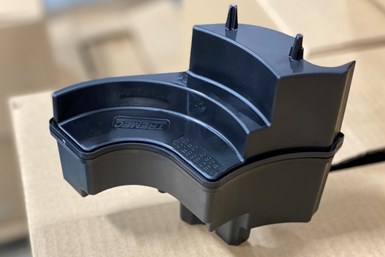

Shah: In June of 2020, a leading manufacturer of torque transfer solutions, including transmissions for leading automotive OEMs, presented a unique challenge to sister company, Pyramid Plastics—an oil baffle.

What was/were the specific challenge(s) with the project?

Shah: The customer's engineers needed an injection molded part that would help them fill the cavity inside a new transmission build while providing stability with efficiency. The challenge was not molding the part; it was the design itself.

The design of an injection-molded part for a new transmission build challenged the Industrial team.

According to the design requirements, the part needed to be 221 grams. Anything weighing more than 221 grams would throw off the balance of the transmission. The customer presented us with a solid part model. The weight of the part was 980 grams, and we needed to reduce the weight by 77%.

What type of solutions did Industrial's engineers consider?

Shah: In the injection molding industry, there are a few pre-existing

The Industrial Molds’ engineering team decided to core out the part to reduce the part’s weight.

techniques to reduce the part's weight. We collaborated with sister company Pyramid Plastics to review a few options—first, the use of a foaming agent. The team determined that foaming agents can reduce the part weight by 12%. The downside of using more dosage is that it could cause the part to disintegrate.

The second approach our engineers looked to implement was to use gas during the injection molding process. The gas fills the inside of the part and reduces the part's weight. After much technical consideration, we established that gassing would not be the best choice. Using gas would increase cost and could compromise quality if the part leaked.

In the end, Industrial Molds’ engineering expertise proved beneficial. The third and winning technique considered was to core out the part. This was deemed the best solution and proved to be the most effective approach in reducing the part's weight. Plus, it allowed us to keep the process as stable as possible without losing reliability since we did not need to use additives such as gas or foam.

Coring the part out helped to keep the proces stable.

Designing a part that had a hollow center resulted in two halves of the part, which we needed to put back together. To do that, our teams collaborated with Dukane, a global provider for plastic welding solutions. We developed the new part design, requiring us to vibration weld the two halves together. This technique is widely used in automotive and medical appliances. Dukane manufactured the welder; we quoted the design, and Dukane suggested adding a seam that we could weld.

The team selected to core out the part, but what was the final design and why?

Shah: The final iteration of the design was a shell of a part that was vibration welded together. We added a seam around the part to provide enough surface in order to do this. The limited space in the transmission restricted the seam's size to only 30% of what was demanded by the welder.

The unique part of this weld was how to capture the flash and debris caused by the weld. If any debris remained on the part, the part would fail in the transmission, as it would have been surrounded by transmission oil. To solve this, we designed a "trap" to capture all of the flash in the seam.

Industrial did not need to use additives such as gas or foam so no process reliability was lost by coring out the part.

We added other design elements like ribs to provide a stable part without any sinks. Pyramid and Industrial used SolidWorks and Creo software. We were able to look at the part design virtually and understand the implications of any design changes in real-time.

I understand the lead time for this project was also challenging. How did the team meet the customer's deadline?

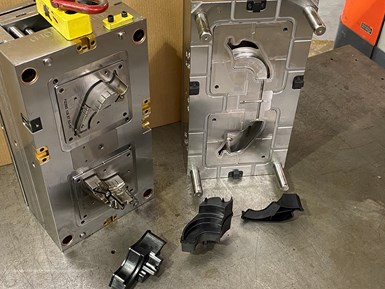

Shah: After long technical discussions with the customer, we all agreed that the design would work for the purpose it was intended and should move into production. Due to a very tight timeline, we were required to complete the tool within 14 weeks. Generally, the lead time for such a complex tool and welding machines is 18 to 20 weeks.

Our engineering team designed the mold, and we followed the advanced quality process (ISO) throughout the mold design. Our project managers are responsible for the mold builds. They follow the material throughout the shop, in the cells through to final mold assembly. Pyramid ran the sample parts the same day as the final mold build. We can sample the same day as tool completion due to the partnership between Industrial and Pyramid.

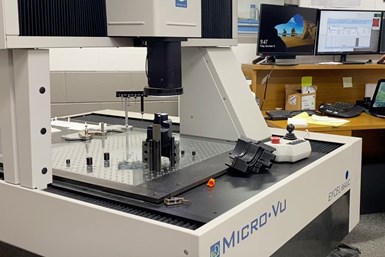

The final step happens in our quality lab. We complete a dimensional analysis with our Micro-Vu Excel 660UC, which measures using its primary camera and other tools such as probes and rotary table. Also, we employed our customer's 3D printer to print the necessary gauges to help us station the part on the Micro-Vu.

A Micro-Vu Excel 660UC is an essential tool in the quality lab for complete dimensional analyses.

With the state-of-the-art equipment at Industrial Molds and expediting the manufacturing process, we were able to deliver our T0 samples by the end of the 12th week. The parts were leak tested and certified for up to 20 psi and could withstand temperatures ranging from 20°C to 140°C. Industrial's automation, especially in the HSM department, was essential for the team to complete this build in record time.

A Makino F5 is a vital machine in Industrial's HSM department.

The mold was complex and required a high amount of machining time within Industrial's HSM department, which comprises a Makino FS6 and F5 to machine the cavity and core blocks. These machines have high rpm spindles, linear drive motors and linear scales that create precise, quality tooling.

The part's design also demanded more complicated, deep ribbing, which required a lot of burning. We produce all of our electrodes in-house and load the magazine to the limit (up to 300 tool capacity). Our two Sodick AG60 sinker EDM machines stayed running to burn the various components needed for this tool build. Further, our automated EDM and HSM cells are capable of 24/7, lights-out production. Our programmers set up the machines and let them do the brunt of the work.

The engineering teams of Industrial Molds and Pyramid Plastics delivered the customer a mold and part that was first deemed impossible.

Related Content

Predictive Manufacturing Moves Mold Builder into Advanced Medical Component Manufacturing

From a hot rod hobby, medical molds and shop performance to technology extremes, key relationships and a growth strategy, it’s obvious details matter at Eden Tool.

Read MoreMoldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

Read MoreTen Things You Need to Know about Circle Segment Milling

Considerations for evaluating if circle segment end mills or conical barrel cutters are right for your mold machining applications.

Read MoreRead Next

2012 Leadtime Leader Awards: Industrial Molds Group

Extensive investment in equipment, technology and its employees coupled with an innovative approach to its mold manufacturing process has earned this mold manufacturer the MoldMaking Technology 2012 Leadtime Leader Award.

Read MoreMoldmaker Adds Automated CNC and EDM Capacity

Industrial Molds Group specializes in engineering molds for medical, packaging, industrial, consumer and automotive markets.

Read MoreIndustrial Molds Celebrates 50 Years in Business in 2018

Founded in 1968 by Jack Peterson, the company has enjoyed continued growth and success. Today, the Peterson family has three generations involved in the business.

Read More_970x90 3.png;maxWidth=970;quality=90)

.png;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)