Technology Tuesday: Mold Maintenance and Repair Products

Cruise through this week’s Technology Tuesday slideshow to see the latest products in mold maintenance and repair.

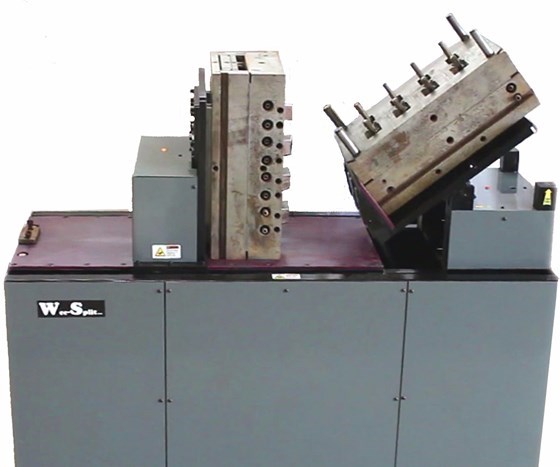

Sometimes, money is better spent on a quality maintenance tool than on a new mold, tool or machine. In that case, what’s the latest in maintenance? This week’s Technology Tuesday blog is a run of the latest maintenance products featured in our print magazine and online. Cruise through the slideshow to glimpse everything from tippers to washers and welders to blast cleaners. You might spot something that will really help your molds and tools perform their best.

Interested in the latest mold maintenance and repair trends and strategies? Check out the Mold Maintenance and Repair Zone. Get the inside scoop from professionals like Steve Johnson, president of MoldTrax and contributor of our “Maintenance Matters” column, or check out our case studies, which will give you insight on what has worked for other shops.

Featured in this week’s slideshow are products from Ransohoff (a subsidiary of Cleaning Technologies Group), Fisa North America, Wee-Split Inc., Cold Jet, LLC, Grieve Corporation, Phoenix Laser Solutions, Amada Miyachi America, Inc. and Die Sep.

Related Content

-

How to Use Thermal Management to Improve Mold Cooling

A review of common mold cooling issues and possible solutions, including 3D printing applications.

-

Laser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

-

What You Need to Know About Hot Runner Systems and How to Optimize Their Performance

How to make the most out of the hot runner design, function and performance.

_300x250 1.png;maxWidth=300;quality=90)

_970x250 4.png;maxWidth=970;quality=90)