With the growing potential and market size of additive manufacturing (AM), companies are investing in driving development. The range of materials is steadily expanding. Refractory metals and high-performance polymers are expected to become available within the next few years and to enable new applications. R&D in multi-laser systems is working toward creating larger building spaces, which will allow for components to have lengths of approximately 2 to 3 meters. Although initially these larger components are likely to be of lower quality than smaller components, multi-laser systems are expected to catch up fast.

Refractory metals and high-performance polymers are expected to become available within the next few years and to enable new applications.

These trends were evident at the Formnext show, which took place this past fall for the third time in Frankfurt, Germany, with 470 exhibitors showcasing an overwhelming number of technologies for tool and moldmaking.

Larger Build Volumes and Multi-Laser Systems

Formnext 2017 offered an optimum platform for AM companies to showcase their developments, including some world-firsts. For example, GE Additive debuted its first piece of GE Additive-branded machinery. The new Additive Technology Large Area System (ATLAS) metal 3D printing machine is a beta technology that teams at GE Additive and Concept Laser developed. It has a build volume of 1.1 by 1.1 by 0.3 meters, and its Z axis is scalable to beyond 1 meter, depending on customers’ requests.

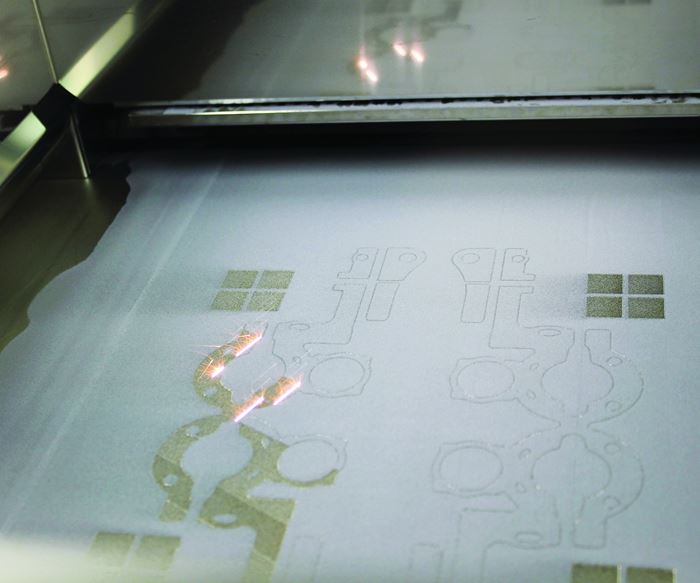

Renishaw introduced its RenAM 500Q, a four-laser metal AM system. The company says it can significantly improve productivity. EOS debuted the EOS P 500, a polymer 3D printing system that enables mass production. Trumpf also is ready for series production with its three-laser, 500-W fiber laser TruPrint 5000, which uses laser metal fusion (LMF) technology to build parts. The three lasers are fitted with optics that Trumpf specially designed. The company says that this enables the lasers to operate simultaneously at any point in the system’s build chamber.

The industry has given much thought to system automation. For example, the TruPrint 5000 is able to start the manufacturing process automatically, which leads to a robust process with less work for the operator. As soon as the build cylinder is placed into the system, it moves automatically to its setup and working position. The integrated zero-point clamping system is the basis for downstream process steps such as EDM, milling and turning.

The industry has given much thought to system automation.

Integration into Existing Processes

The catchphrase is process integration. The future of AM lies in its integration into current manufacturing processes to reduce steps, time to market and costs. The future of AM also lies in the intelligent combination of conventional machining technologies and AM.

The catchphrase is process integration. The future of AM lies in its integration into current manufacturing processes to reduce steps, time to market and costs. The future of AM also lies in the intelligent combination of conventional machining technologies and AM.

AM processes have long been considered stand-alone technologies that did not fit easily into machining process chains. Marketing strategies were suggesting that one either manufactures with conventional subtractive machining technologies or with AM technologies. Many production managers simply never realized that these two worlds can and should be combined to yield the most optimum results.

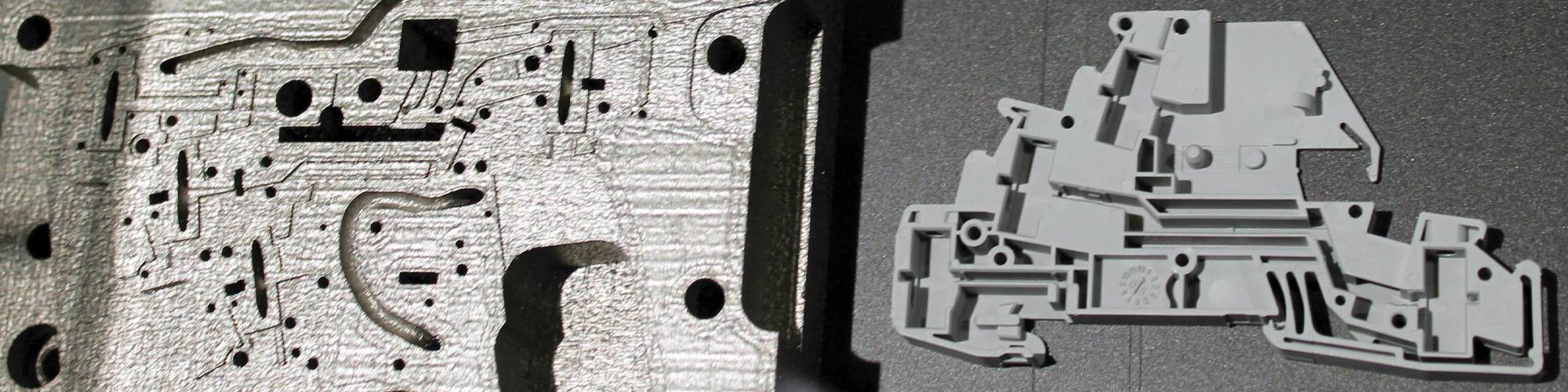

This is particularly true for moldmaking, where AM has long found its place in the integration of conformal cooling channels in molds and mold inserts. Laser sintering is useful as well for making sintering density changes in molding applications that require the placement of porous structures to facilitate gas venting. In addition, laser sintering enables the production of deep features by building them one layer at a time, eliminating the need to machine these features with EDM.

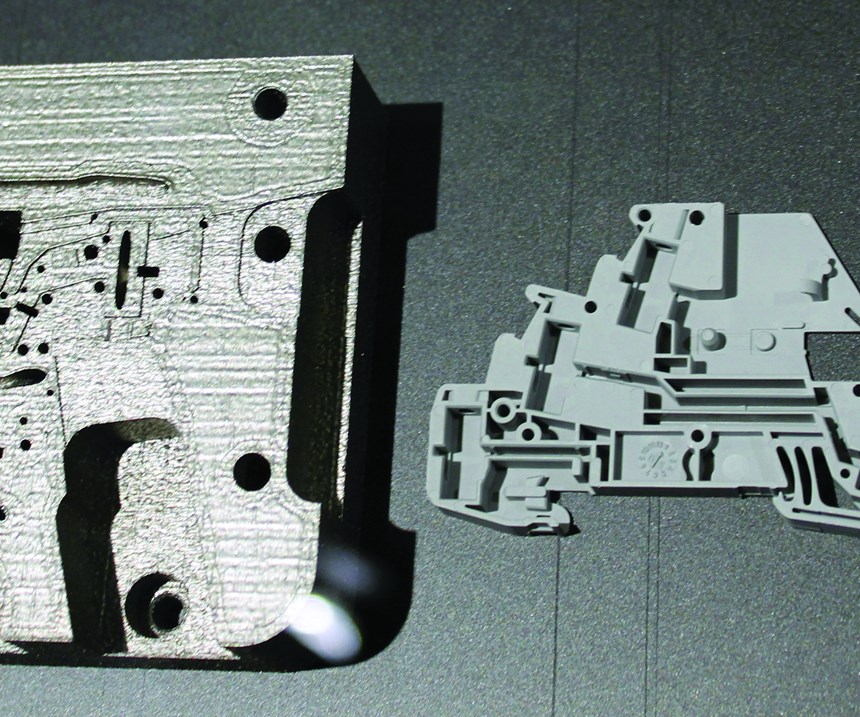

Two companies that realize moldmakers need solutions, not single machines or technologies, are GF Machining Solutions and EOS, and they have partnered to combine their technologies to benefit the moldmaking sector. The AM S 290 Tooling machine, which is based on the EOS M 290 DMLS system, is designed to address the mold and die industry’s need to produce innovative mold inserts using AM. GF Machining Solutions and EOS aim to integrate AM machines into the production process of mold inserts, including the necessary software and automation link with downstream machine tools and measuring devices.

The Technical Unit System 3R zero-point clamping solution from GF Machining Solutions works in a similar fashion to the Trumpf zero-point clamping system. The Technical Unit System 3R ensures that the workpiece moves along the various production steps maintaining the same zero-point, eliminating errors and setup times. The system consists of a reference platform (3R Masterpal) and multiple component-specific mini pallets (3R Minipal) on which additively manufactured parts are printed.

This can be particularly useful when manufacturing hybrid parts. The first step in producing hybrid parts is milling or turning where the workpiece is set up, referenced and machined. To add material via selective laser melting (SLM) or other AM processes, the part is placed into the AM machine and usually loses all of its reference points. The same is true for post-processing steps like milling. Using the reference platform eliminates multiple setups and corresponding errors. Since the additive process is quite expensive, conventionally machining the core or the insert and reserving AM only for the parts with conformal cooling channels is a cost-efficient solution for mold shops producing hybrid parts.

The first step in producing hybrid parts is milling or turning where the workpiece is set up, referenced and machined.

Hybrid Machines Offer the Best of Two Worlds

Hybrid AM machines offer a combination of layer-by-layer building and conventional subtractive machining. Consequently, the giants of the wider manufacturing world did not miss the opportunity to showcase their latest developments at Formnext. Companies with something to display included DMG MORI, Matsuura, Hermle, OR Laser and Sodick.

Sodick’s OPM250L combines direct metal laser sintering (DMLS) with high-speed milling and is primarily designed for moldmakers. In addition to creating conformal cooling channels, the OPM250L enables the machining of workpieces before the additive process is complete. The OPM250L alternates between milling and laser sintering, which reduces the number of parts necessary to build a mold. Sodick also follows the trend of developing products that enable manufacturing at higher speeds. In a setting called “Parallel Mode,” the OPM250L can grow parts at three locations simultaneously. Sodick designed the OPM250L to require only a single beam to accomplish that task. Sodick explains that this is because laser sintering equipment must take fumes and shape deviation into consideration when generating the laser path. For this reason, the laser unit is not necessarily utilized at full capacity during processing. In parallel mode, the machine makes optimal use of the laser unit by targeting multiple locations concurrently.

Matsuura showcased its latest hybrid machine, the Lumex Avance 60, which opens this technology to bigger applications in new industries, such as aerospace and automotive, accommodating a maximum workpiece size of 600 by 600 by 500 millimeters and a maximum weight of 1,300 kilograms. New products are available for those who do not want to go big. For instance, OR Laser, a German laser systems manufacturer, debuted the Orlas Creator hybrid, an SLM machine with the added benefit of three-axis milling to create net parts. The machine combines the build platform of the original Creator, an SLM machine that OR Laser launched at Formnext 2016, with a 250-Watt laser and processing speeds of 3,500 millimeters per second. The Orlas Creator hybrid would fit even a small workshop environment.

Tomorrow’s Injection Molds

Protiq, part of the Phoenix Contact Group, showcased an injection mold that the company developed with the design freedom of AM in mind. The injection mold leverages simulation and numerical optimization to address the structural, thermal and manufacturing aspects of designing an injection mold. Designed for in-house use at Phoenix, the mold is 75 percent lighter than the original tool that the company created a couple of years ago with traditional methods.

Conformal cooling was integrated into the AM process, which reduced the cycle time by 3.2 seconds. “It is one of the fastest tools we have ever built at Phoenix,” Protiq Managing Director Dr. Ralf Gärtner says. “Of course, the topology optimization in this mold doesn’t necessarily make sense for all kinds of tools, like 128-cavity molds. Additively manufactured molds or mold inserts do not replace traditional moldmaking by any means. The question is: How do shops complement their existing portfolios?”

“Additively manufactured molds or mold inserts do not replace traditional moldmaking by any means. The question is: How do shops complement their existing portfolios?”

About the Author

Barbara Schulz

Barbara Schulz is Gardner Business Media’s European correspondent. She can be reached at bschulz@gardnerweb.com.

Related Content

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

Read MoreConsiderations for Mold Base Material Selection

Choosing the right material can greatly affect the profitability and cost of your application.

Read MoreFundamentals of Designing the Optimal Cooling System

The right mold components can help improve mold cooling and thereby produce higher-quality parts.

Read MoreMachining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

Read MoreRead Next

Are You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More.jpg;maxWidth=970;quality=90)

.jpg;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)