Matsuura Machinery USA Inc.

325 Randolph Ave.

Suite 100

Saint Paul, MN 55102 US

866-748-3827 | 651-289-9700

info@matsuurausa.com

matsuurausa.com

IS THIS YOUR COMPANY?

As Seen On MoldMaking Technology

Matsuura Machinery USA Inc. Supplies the Following Products

- All Other Workpiece Handling, Loading & Feeding Equipment

- CNC Turn/Mill Machines

- for Composite Parts

- for Metal Parts

- High Speed Machining Centers

- Horizontal, Five-Axis

- Horizontal, Up to Four-Axis

- Hybrid AM Machines

- Lathes

- Material Removal Automation

- Pallet Changers, Shuttles & Programmable Transfer

- Powder Bed Fusion

- Universal Milling Machines

- Vertical, Up to Four-Axis

Editorial, News, and Products

-

Technology and Sourcing Guide 2023: Additive Manufacturing

3D printing, or additive manufacturing, simplifies the moldmaking process by making mold inserts, mold components, end-use parts and ancillary equipment. Access this exclusive, online-only content, including a suppliers list, AM products and more.

-

Indiana Mold Builder Decatur Mold Offers a History of Grit and a Future of Innovation

Decatur Mold Tool and Engineering Inc. serves as a tooling tour guide, helping busy tooling managers reduce uncertainty, lighten workload.

-

MoldMaking Technology's Most-Viewed Content 2022: Products

MMT shares the five top-viewed technologies, equipment and services of 2022 in each Engineer, Build, Maintain and Manage tenet based on Google Analytics.

-

30 Under 30 Honors Program: Mentoring in the Next-Generation of Moldmaking Professionals

Young professionals are vital to the moldmaking industry, and it is important to acknowledge those making strides in shaping the industry's future. MoldMaking Technology recognizes the industry's young talent through its 30 Under 30 Honors Program.

-

IMTS 2022 in a Flash

With this still being the month of IMTS, I thought I’d highlight some of the technology mold builders have expressed growing interest in and are actively investigating, and what was on the show floor.

-

Get Ready for IMTS With These Mold Manufacturing-Focused Exhibits

It’s always important to visit IMTS with a general plan of action. MMT editors help familiarize you with several machining, software, cutting tool, EDM and mold repair innovations that will be exhibited and are geared toward moldmaking.

-

Hybrid Metal 3D Printer Redefines Mold Component Production

Matsuura Machinery is highlighting several of its high-speed, Industry 4.0 five-axis VMC and HMC machines at IMTS 2022, as well as its LUMEX metal 3D printing expertise for moldmakers.

-

Lights-Out Metal 3D Printer Minimizes EDM Needs for Moldmakers

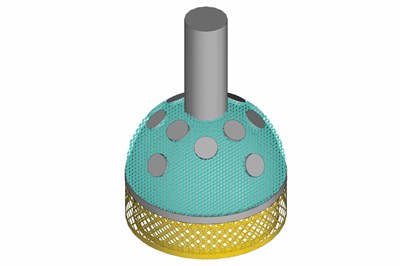

The Matsuura LUMEX series boasts both forming and milling capabilities in one unit, achieving highly accurate mold component production, with the ablity to integrate conformal cooling and porous venting.

-

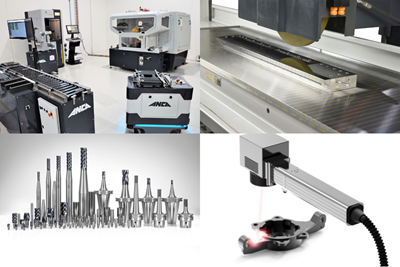

Cutter Considerations for Hybrid Additive Manufacturing

Four tips for applying the right cutting tools in hybrid additive manufacturing.

-

30 Under 30 Class of 2021: Design/Engineering/Program Management

MoldMaking Technology covers the next-generation moldmakers recognized under the 30 Under 30 Honors Program that engineering, design or program managers at their company.

-

MMT Chats: 30 Under 30 Honoree, Application Engineer Empowers Innovation

MoldMaking Technology Editorial Director Christina Fuges chats with Matsuura USA Application Engineer Nick Mitchell on this MMT Chat. He shares his passion for learning, reliance on mentoring, mission to change traditional mindsets when it comes to AM and his desire to put his industrial engineering background to work. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

-

30 Under 30 Class of 2021: Midwestern Moldmaking Talent

MoldMaking Technology celebrates the next generation of young professionals based in the Midwest that are making an impact in mold manufacturing.

-

Metal Additive Manufacturing Machine Series Enables High-Volume Mold Component Production

The Matsuura Lumex series system implements conformal cooling and integrated porous venting, reducing EDM processes and capital equipment investments for tooling and molding machines.

-

Matsuura Machinery Appoints Mike Bruegger to Application Engineer Position

Mike will train and support distributor engineers and Matsuura customers in the operation and troubleshooting of all company machining centers, support five-axis automated manufacturing solutions.

-

2020 Sourcing & Technology Guide: Additive Manufacturing

MoldMaking Technology’s annual Technology Review and Sourcing Guide is a comprehensive guide for researching today’s technology, equipment, products and services with 11 sections, including Additive Manufacturing.

-

Hybrid Milling Machine Effectively Vents Gas

Matsuura Machinery USA Inc.’s Lumex technology makes effective mold/gas venting possible and improves the quality of molds.

-

Hybrid Additive Machining Produces Accurate Parts from Metal Powders

Hybrid additive/subtractive machining produces highly accurate parts from metal powders that are melted and sintered using a laser while surfaces are precisely milled at high speeds.

-

Matsuura Machinery USA Announces Personnel Changes

Matsuura Machinery USA, Inc. announces personnel additions and promotions.

-

Expertise in Mold Repair and Revisions Makes Quality Mold Inc. A Valuable, Full-Service Resource

Quality Mold Inc. does everything in house including mold repair and refurbishment. Customers also benefit by a mold warranty, financing and guidance.

-

PODCAST: A 3-in-1 Force in Mold Manufacturing Looks for Problems

This mold manufacturer considers itself an engineering company with a focus on people and solving problems. In this episode of The Manufacturing Alliance, we dissect how three companies operate as one to provide creative solutions to complex manufacturing challenges.

-

VIDEO: Custom Mold & Design Talks Hybrid Additive Manufacturing

Lester Jones, VP of Custom Mold & Design discusses the shop's use of its Matsuura Lumex Avance-25 hybrid AM machine for creating conformal-cooled inserts with MoldMaking Technology Editorial Director Christina Fuges.

-

Mold Builder Learns How to Use Hybrid AM to Build Conformal-Cooled Inserts

It is one thing to understand additive technology, but it is another to know when to invest, who to partner with and how to sell its value.

-

Video: Metal AM Affects Plastics Production via Conformal Cooling

Additive manufacturing allows cooling channels within mold tooling inserts to follow the form of the tool rather than being straight drilled holes. Here’s why this matters.

-

Matsuura USA Expands Personnel

Due to continued growth in recent months, Matsuura Machinery USA has expanded its sales and service departments, in addition to enlarging the staff of the Matsuura USA LUMEX Additive Manufacturing Center.

-

Live Show Floor Recap from Amerimold 2019

In the midst of exhibitors breaking down at the close of Amerimold 2019, the MoldMaking Technology editorial team set up shop at the MMT booth to do a live Manufacturing Alliance Podcast, sharing some immediate insight and feedback on this annual event.

-

2019 Leadtime Leader Award Winner: X-Cell Tool and Mold Inc.–The Continuous Drive for Perfection

Continued investment in new technologies and automation has enabled this moldmaker to maintain shorter lead times no matter how large or complex the mold build.

-

Amerimold 2019: Attendees Will Benefit from Educational In-Booth Demos

Amerimold presents in-booth demonstrations of 3D printing, machining, hot runners, mold maintenance, molding, and more.

-

Matsuura Machinery USA Announces New Personnel Appointments

Shannon Collett is named Matsuura LUMEX Administrator and Cassandra Yanke is promoted to Logistics and Project Manager.

-

Hybrid Milling Machine Fuses Metal Laser Sintering and High Speed

Matsuura Machinery USA, Inc. will exhibit the Lumex Avance-25 metal laser sintering hybrid milling machine at Amerimold.

-

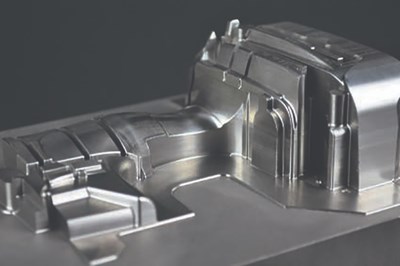

Custom Mold & Design Chases Complex Mold and Production Part Projects with Top-of-the-Line Five-Axis, Screw, Mill/Turn, Additive and Molding Machines

Unique business model—with an eye on complex projects and an arsenal of machine technology to meet the required accuracy levels—raises the bar in mold and machined component manufacturing.

-

The Most Viewed Products of 2018

MoldMaking Technology wraps up the year by showcasing the most-viewed products of 2018.

-

Matsuura Announces Partnership with CMD

CMD and Matsuura USA are collaborating in applying the Matsuura Lumex technology for the mold industry.

-

IMTS 2018: Process,Technology and Service Advancements

Advancements in automation and digital manufacturing took center stage during IMTS last week, but developments in additive manufacturing, cutter technology, machining solutions, simulation software, EDM, laser technology and customer service were other hot items.

-

IMTS Ripe with Mold and Die Technology

The complexities and tight tolerances of mold work make it a very demanding trade.

-

Automation and Connectivity Drive Machine-Tool Innovations

Machine tool and EDM suppliers are advancing their offerings to include automation, better controls, machine monitoring and new five-axis capabilities.

-

2018 Technology Review and Sourcing Guide: Machining

MoldMaking Technology’s annual Technology Review and Sourcing Guide is an accurate, comprehensive, easy-to-read and easy-to-use use guide for researching today’s technology, equipment, products and services. The year’s latest moldmaking product developments within mold engineering/design, build and maintenance/repair are broken down into 10 sections, including machining.

-

Machines Feature Automation, Hybrid Capabilities and More

Matsuura USA showcases eight machines at IMTS 2018. Several of them are on display for the first time at the show.

-

Tradeshow Tuesday: On Display at Amerimold 2018, Part 5

Amerimold 2018 is just around the corner, so check out this week’s slideshow of items to see some of what will be on display at the show.

-

Machine Combines Processes for Finished Parts in Fewer Setups

The Lumex Avance-25 combines selective laser sintering (SLS) with high speed milling (HSM), which is commonly called hybrid additive manufacturing.

-

AM Platform Recycles Powder for Safety and Efficiency

The Lumex Avance-60 is a product from the Matsuura Lumex Avance series, which are now available in North America from Matsuura Machinery USA, Inc. The series are made of powder bed, metal additive manufacturing (AM) platforms with subtractive capability that combine laser sintering and high-speed milling.

-

Stand-Alone Additive Manufacturing Is a Thing of the Past

Additive manufacturing (AM) is no longer considered a stand-alone technology but is increasingly being integrated in existing manufacturing processes.

-

Technology Tuesday: A Mix of Machining Products

Cruise through this week’s Technology Tuesday slideshow to see the latest products in machining.

-

Matsuura USA Completes AM Platform Production Center

Matsuura USA completed the development of a Lumex Center of Excellence at its headquarters in St. Paul, Minnesota. The facility installs Lumex Avance Series machines, which are AM platforms that combine additive and subtractive processes.

-

Machine Combines Additive and Subtractive Processes for Quick Turn of Custom Parts

The Lumex Avance-25 is a product from the Matsuura Lumex Avance series, which are now available in North America from Matsuura Machinery USA, Inc. The series are made of powder bed, metal additive manufacturing (AM) platforms with subtractive capability that combine laser sintering and high-speed milling.

-

Digital Ed. of MMT's May Additive Mfg. Supplement Ready

This month's edition features stories on how to push additive manufacturing to the next level with a commitment to customer service, education and training, as well as a look at one manufacturer's year-long journey with additive manufacturing.

-

Laser Sintering and Milling Working Together

A hybrid manufacturing process offers mold builders an alternative method for making cores and cavities with time and cost savings and increased consistency.

-

Laser Focused on Moldmakers

A new partnership brings to North America a metal laser sintering hybrid milling machine that can fabricate molds and dies with very complex geometries in one piece with high accuracy, shortening lead time and reducing manufacturing costs.