PODCAST: A 3-in-1 Force in Mold Manufacturing Looks for Problems

This mold manufacturer considers itself an engineering company with a focus on people and solving problems. In this episode of The Manufacturing Alliance, we dissect how three companies operate as one to provide creative solutions to complex manufacturing challenges.

Share

Read Next

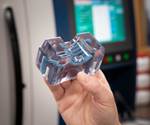

The mission of Minnesota-based Custom Mold & Design, Paradigme Engineering and Teamvantage is to help customers develop products, not just new molds. This effort involves 320 people across three facilities all involved in ultra-precision part and mold work for implants, surgical tools, pacemaker programmers, diagnostic equipment, hospital bed components and chemotherapy delivery systems. How the team is able to accomplish all of this made for an interesting discussion during this episode of The Manufacturing Alliance Podcast with the company’s VP Lester Jones and Vice President of Sales Tom Caron.

Listen to our conversation here:

For more podcasts click here.

Related Content

-

6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

-

Treatment and Disposal of Used Metalworking Fluids

With greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are “consumable” and have a finite life.

-

Considerations for Mold Base Material Selection

Choosing the right material can greatly affect the profitability and cost of your application.