Decatur Mold specializes in injection mold building, quick turnaround prototype builds and emergency repairs. Photo Credit, all: Decatur Mold and Engineering

Who is Decatur Mold Tool and Engineering Inc.?

Louie Fields, director of operational efficiency, Decatur Mold Tool and Engineering Inc.: Decatur Mold Tool and Engineering was founded in 1966 in a 2,400-square-foot facility with five toolmakers. Over the past 56 years, we have grown into a world-class manufacturing business with 130 employees and an 87,000-square-foot manufacturing facility (61,000-square-foot air-conditioned manufacturing area, 14,000-square-foot area for the office, engineering and training; and a 12,000-square-foot climate-controlled warehouse. Plus, floor and trailer height unloading facilities).

Decatur Mold is adding 14,320 square feet of automation manufacturing space to its facility by August 2023.

We are currently constructing a new 14,320-square-foot expansion onto the existing facility, which will house the latest technology for lights-out manufacturing — including three new robot cells with integrated automation (five-axis machining, five-axis electrode machining and EDM), aiding our new mold building projects.

Decatur Mold specializes in all aspects of injection mold building, from those emergency repairs to quick turnaround prototype builds, new product mold builds and a defense contract division that produces some of the latest technology, keeping our servicemen and women safe.

Decatur Mold has eight full-time designers who use NX software, including Charles Maynard (left) and Shawn Kidwell (right) pictured here.

Decatur Mold also offers low-volume production runs/sampling in our nine presses ranging from 74 to 946 tons. Our capabilities include gas-assist, hydraulic and pneumatic valve gate systems, multiple hydraulic actions and RJG certification.

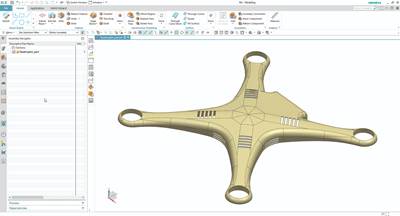

Our core competencies are designing, building and servicing production and prototype plastic injection molds, low-volume production part runs, three-axis CNC machining (horizontal and vertical), five-axis CNC machining, CNC sinker and wire EDM, CNC turning, live tooling, reverse engineering and high-speed light scanning.

We serve the appliance, automotive, consumer products, container, aerospace, medical and military (ITAR-registered) industries. In addition, as an ITAR-registered injection mold builder, our team is entrusted by the Department of Defense to design and build prototype plastic injection molds for various government entities.

Machinist Justin Rennemeier sets up Decatur's current Erowa robotic cell to run unattended for the weekend.

Our arsenal of technology includes Siemens NX, PTC CREO, Solidworks, Catia v5, Ideas, Toyoda, Makino, Matsuura, Deckel MAHO vertical and horizontal mills, Makino EDMs, Okamoto surface grinders, Okuma turning center, Tarus drilling machine, Brown & Sharpe CMM, FaroArm with a blue light scanner, new ATOS ScanBox, Alpha Laser and OR Laser welders, a 400-ton Millutensil spotting press (118 inches × 94 inches) and nine Nissei molding presses ranging from 74 to 946 tons and 17 Conair dryers.

Since 2004, Decatur Mold also has a 22-employee design and project management operation in a technical center in Shenzhen, China, that manages offshore mold builds. We understood our customers’ needs for low-cost tooling backed by high-quality standards, so we started Strategic Sourcing LLC to oversee quality alongside a project team in the U.S. that is the customer’s point of contact. We stand behind the quality of our molds and tools, built here in the U.S. or at our overseas facility.

Additionally, our company is an active foreign trade zone with our own customs broker to ensure a quick and seamless import process.

What do you view as your chief competitive advantage?

Fields: We excel because of our team. We have talented, loyal, customer-focused tooling experts alongside the latest technology.

President Rhonda Hoerle says, “End-to-end, we take full command over planning, production and delivery, utilizing our people, equipment and trucks, ensuring everything is produced to our standards and handed to our customers on time.”

During the pandemic, we created a culture of ongoing training, and every permanent employee now has an individual development plan designed to support their career aspirations.

Provide an example of the most significant change in your use of technology.

Fields: We purchased our first robot to automate an EDM cell in 2020. We have not only enjoyed the improved productivity it offers but are ready to apply the lessons we learned to our new mold manufacturing expansion.

Along with the robot, we implemented EDM software to automate programming and remove locations’ manual input, eliminating entry errors and increasing efficiency in the area.

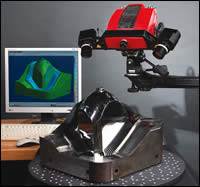

We also use high-speed optical 3D scanning via robotic automation to expand and streamline our metrology capabilities. For example, in 2021, we purchased an ATOS ScanBox with an ATOS 5 high-speed 3D laser scanner that dramatically improved our reverse engineering and inspection capabilities.

The ATOS sensor is a self-monitoring system, which means the sensors software continuously monitors the calibration status, the transformation accuracy, environmental changes and part movements to ensure the quality of the measuring data.

The ATOS Plus intuitively integrates photogrammetry with ATOS 3D scanners to further advance automation. This dynamic combination enhances measurement accuracy and repeatability and eliminates the need for costly precise fixtures.

We use the ATOS to inspect tooling to ensure the final machining matches the 3D data — 3D contours, hole locations and alignment between both halves of the tooling. We also scan to find interference areas or hard-to-find shut-off issues and inspect tools during production to define wear areas.

The scanner also ensures the final product matches the 3D data — 3D contours, print and print tolerances deviations. In addition, ATOS provides fully automated full-field deviations between the actual 3D coordinates and the CAD data. As this measuring data contains all the object information and the surface deviations from the CAD, the software automatically derives detailed information such as geometric distancing and tolerancing (GD&T).

Last but not least, we use the ATOS for reverse engineering. For example, with an irregularly shaped object, it can be challenging to get an accurate picture of its condition using traditional inspection methods. Instead, the laser scanner inspects and records every detail of the object’s surface, regardless of its construction, to deliver the necessary data. You will then have a clear indication of the fitness of the part, backed by measurable and factual results. The ATOS 5 provides the data needed to design and manufacture the reproduction component. It also enhances hot mold repairs when no data is available, quickly collecting the data to allow surfaces to be machined back to production-ready status.

How has your approach to business changed over the years?

Fields: We have been working to increase capacity and productivity in anticipation of the current reshoring by focusing on training and technology. During the pandemic, we created a culture of ongoing training, and every permanent employee now has an individual development plan designed to support their career aspirations.

We also installed machine utilization monitoring software from InFocus from R.E.R. Software to generate data that helps the team make better decisions around workflow and capacity. For example, we can now plan for staffing and future capital purchases by providing visibility into when machines are running. The software helps us collect data from the machines, such as spindle time, unmanned hours, setup time and, most important, the reason the machine is down. Operators input notes when the machine has stopped for a period of time.

We excel because of our team. We have talented, loyal, customer-focused tooling experts alongside the latest technology.

Is your company having a difficult time finding and attracting new employees? If so, how are you addressing the skills gap?

Fields: We are having a difficult time finding new employees. We are seeking to fill positions in all areas of our business, from apprentices to project managers to senior technical sales. We help teachers from our local and surrounding high schools understand the skill set and work ethic necessary for our trade.

We sponsor the local high school electric go-cart team, which enables us to work directly with a group of young talent to build, develop and research battery power, then put it to the test on the track. The kids work here at our facility in the evenings. We actually had a couple of students fill out an application. In this past year’s Christmas parade, our company float featured the team and the go-carts.

Decatur Mold president Rhonda Hoerle says the company excels because of its people, so improving employee benefits and maintaining a family culture is a continual focus.

One notable change we made to help retain employees was increased personal time off (PTO). Now, a new hire will start with 80 hours of PTO time after 90 days in addition to our existing benefits package (a competitive wage, 401K match, medical, dental, eye).

Also, during the pandemic, we adopted hybrid working environments for some employees. We have continued this policy and are trying to leverage it to recruit in positions where it makes sense. Some of these changes are working, as we hired several new employees over the past few weeks, but we still have positions open.

Describe the most interesting/notable mold project your company was awarded.

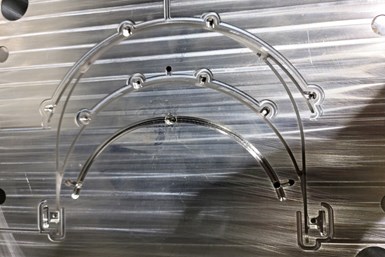

Fields: During the pandemic, Decatur Mold was challenged by a customer to make plastic headbands for face shields. The customer was 3D printing the headbands, but could not keep up with the demand. Typically, it would take three to four weeks to build a plastic injection mold, but Decatur responded to the challenge and built it in three days. This included R&D, design, machining, assembly and processing the mold to produce good-quality parts.

A production mold for a plastic face shield headband demonstrates the expertise of the Decatur team when it came to producing this tool in three days, which included R&D, design, machining, assembly and production. Photo Credit: Decatur Mold, Tool and Engineering Inc.

Once word got out about the mold we built, the Army contacted our owner to place an order. We reached out to the customer who requested the original headband mold and asked if we could use the design to build a mold for the Army. The customer graciously agreed to the request.

Decatur then built a second mold, with which we produced and donated hundreds of face shields to local hospitals, medical offices, dental offices, nursing homes, schools and other local essential companies.

Related Content

The Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

Read MorePortable Low-Heat, Non-Arcing Resistance Welder for Mold Repair

Rocklin’s user-friendly MoldMender Micro Welder delivers simple and cost-effective localized repair in-house with precision and versatility, enhancing mold and die durability and reducing disassembly and downtime.

Read MoreWhat is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

Read MoreSurface Finish: Understanding Mold Surface Lingo

The correlation between the units of measure used to define mold surfaces is a commonly raised question. This article will lay these units of measure side by side in a conversion format so that companies can confidently understand with what they are dealing.

Read MoreRead Next

How to Pre-Estimate Tooling Costs

The right costing software can help to improve mold quoting and production.

Read MoreFive Things a Mold Builder Should Know about Non-Contact Blue Light 3D Scanning

Mold builders who use non-contact blue light 3D scanning reap the benefits of digitization throughout the mold manufacturing process.

Read MoreTaking Technology to New Heights

White light, non-contact scanning system adds new capabilities including real-time inspection.

Read More

.jpg;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)