Manufacturing Execution System Automates Task Scheduling for Forward-Thinking Mold Shops

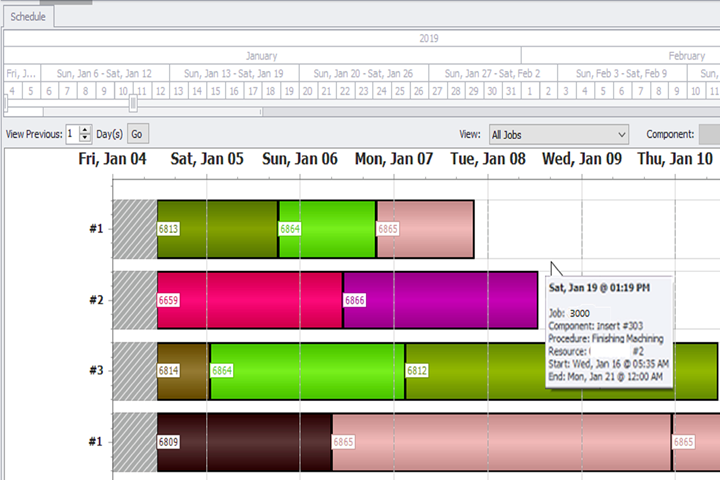

The R.E.R Software AutoPlan is a living schedule, capable of aligning hundreds of thousands of tasks with varying capabilities while reacting to the complexities of manufacturing facilities.

R.E.R. Software’s AutoPlan product was built with automation at the core. Moldmaking is a very competitive market, and automation cells are becoming the reality for forward-thinking shops. One of the largest challenges facing these shops is having available work prepared and ready for the automation cell. This is where R.E.R.’s InFocus suite and more specifically, AutoPlan, shines, according to the company.

AutoPlan is said to remove all of the struggles that are associated with manual scheduling. Employees no longer have to walk the shop floor to see what is ready, or if the material is received and prepared. A living schedule, AutoPlan is continuously shifting and reacting to real-world situations and complexities in a manufacturing facility. It is aware of the status of all parts, and plans the work in the exact order required to make sure work is queued to maintain the due dates.

AutoPlan is a state-of-the-art manufacturing execution system (MES). Compared to what Microsoft Project does with one job, R.E.R. says Autoplan does automatically with the company’s entire workload. The software understands each resource capability and knows what work can, and cannot, be performed on it. Moreover, when combined with InFocus AutoTrack, AutoPlan is in constant communication with all equipment in real time, logging hours to the correct task every time, also automatically. While AutoPlan works as a standalone complete scheduling system, when combined with the company’s machine monitoring system, AutoTrack, it is said to provide for compounded returns.

Related Content

-

Ten Things Mold Builders Should NOT Do

What you don’t do can be just as important as what you do, sometimes even more so. One thing great mold builders do is take note of what gets in the way of their success and stop doing it.

-

OEE Monitoring System Addresses Root Cause of Machine Downtime

Unique sensor and patent-pending algorithm of the Amper machine analytics system measures current draw to quickly and inexpensively inform manufacturers which machines are down and why.

-

Take Time to Save Time: 6 Steps in Mold Design to Reduce Back-End Troubleshooting

Westminster Tool shares how the one week it typically takes to perform these six steps in the design phase can save three weeks or more in an overall tool build.

_300x250 4.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)