“Most mold builders intend to design out the complexity of a customer’s part. Here at Custom Mold & Design, we are looking for work for which we can leave in the complexity and bring outsourced operations in house. We believe that the more layers customers add, the more valuable we are to the customer. Our true value is being used early on in the design process,” Lester Jones, Vice President of Custom Mold & Design of Forest Lake, Minnesota says. This philosophy has served the company well over the past 54 years.

Custom Mold & Design considers itself an engineering company. “We help people develop products, not just new molds,” Owner Ray Newkirk says. “We find creative ways to solve complex problems.” And that means its 320 people across three facilities do a lot of work for which one-thousandths of an inch makes a difference. Jones calls this “cringe work” and not because of the tight tolerances it demands, as much as it is a product portfolio that consists of life-saving things people hope they never need: ultra-precision work that changes lives, such as implants, surgical tools, programmers for pacemakers and different regulators, hospital bed components, and chemotherapy process reservoirs (for high-temperature chemo drugs). Custom Mold & Design works in highly regulated industries with products that seem different, but in reality, the requirements are very similar. Forty percent of Custom’s customer base is medical, 25 percent is defense and the rest is spread across the aerospace, electronics and consumer products industries. Plus, this sought-after complexity drives reshoring, a positive side effect in our globally competitive marketplace.

One key component of this business philosophy is machine technology, and you don’t have to be on the shop floor long to notice they are tooled up just right to support this strategy.

Beyond Accuracy and Speed

Within the past six months alone (back in October 2018), Custom Mold & Design purchased seven semi-truck loads of equipment from an Ohio auction, on top of the equipment it already has in place. This arsenal of machine technology equips this mold builder to take on tough-to-tackle molds and production parts, as well as overmolding, metal injection molding (MIM), silicone and multi-shot work. Strategically purchased machine tools and presses help produce the accuracy levels demanded by the markets Custom serves. Current machining equipment includes CNC machining centers, CNC turning centers, graphite machines, sinker and wire EDMs, grinders and additive manufacturing machines from a variety of machine tool builders.

This machine technology permits Custom to take on work others won’t, like a family of titanium mesh/PEEK spinal implants that are laser sintered, wire EDM’d, overmolded, laser marked and five-axis milled. The Custom team molds PEEK (polyetheretherketone) to the porous titanium material, so it is bonded to the inside layer which leaves the outside layer for the bone to grow into. This product is all about tight tolerances (two-tenths), as it must fuse to the lower back. Custom procures additively manufactured titanium plates that have a porous plate with a solid layer, then a layer of porous material, which the shop wire EDMs to fit the mold cavities.

Custom’s sister company Teamvantage (located four miles down the road) then injection molds the components returning them to Custom Mold & Design, which then machines the titanium mesh spinal implant parts in one of two five-axis Yasda micromachining centers. Each part is loaded onto automated pallets that run unattended. “We hit the button, and the cell runs all weekend. We come into work on Monday, and 60 pallets with four parts per pallet have compound angled holes machined in perfect locations,” Jones says). Finally, a metal insert plate is installed, the part is laser engraved, cleaned, packaged and ready for sterilization. Patient kits for the doctors comprise multiple different sizes. “A project like this requires the technology to do every process for each part,” Jones says.

Custom Mold & Design does not shy away from these complicated projects. They buy the technology they need to do the job. For example, a tight-toleranced, two-cavity LSR tool Custom designed and built for a firemen’s face mask, which has slides pulled in multiple directions. Custom bought a Yasda Vi40 five-axis machining center specifically for this job. “Most LSR tools are sampled and end up with flash, so you need to work on shutoffs to get the flash tightened up, but we can build tools so tightly fit together that we can’t fill them. They are so tight that you can’t get the air out of them. You have to go in and selectively vent it,” Jones says.

These are just two examples of how Custom Mold & Design has raised the bar in mold manufacturing with its machining technology. It all started when the shop attempted hard milling back in 2004 but failed because of the machine choice. The operators were having such a hard time with the equipment that they would rather EDM. The Yasda YBM 640V was the answer. Its accuracy and surface finish capabilities were at the level their customer’s work required. Custom Mold & Design evaluated many machines, and although they might be as accurate and as fast, the surface finish with other machine tools cannot compete with that of a Yasda.

The company now has a total of nine Yasdas, three of which are five-axis machines (Methods Machine Tools, Inc. represents Yasda across North America). “The lines of code flying through the five-axis machining centers is crazy, and the capability to hold the tolerances we do while swinging a big block of steel on the table is nuts!” Jones says. “And just down the aisle, we are cutting hardened tool steel with a 0.004-inch-diameter end mill. That’s just bigger than a human hair. When I worked on the shop floor many years ago, I couldn’t have imagined such things, and now the guys do it every day. It boggles my mind!”

At the time of my visit, Custom Mold & Design had a mold sitting on the shop floor that runs at 375-425oF with slides pulling at angles with many complex shutoffs. With silicone, if there is a half-thousandth gap, it will flash. “This mold demands a precision fit for every component. They have to be perfect to eliminate flash, and by using the right software, cutters, machine tool and skilled personnel, we can produce the accuracy and the surface finish required. If we eliminate polishing, we increase accuracy. Our five-axis Yasda does the trick every time,” Jones says.

However, when it comes to accuracy, the real challenge according to Newkirk is bringing all of its work, which is being completed across multiple facility locations, together to fit. The molds are run all over the world, so customers demand interchangeable parts that must be built to the numbers. Again, Yasda has been the answer to this demand. Even two lightly used Yasdas Newkirk purchased, with all the tooling for parts and mold manufacturing from a bankrupt company, perform at the required speed, accuracy and surface finish levels.

“Making billions of things is boring. We want work for which we can use our engineering and problem-solving capabilities. We are constantly practicing and honing our skill level, so we want customers who need us to do the hard, challenging stuff.”

Strength in Numbers

As Jones mentioned earlier, it takes more than one kind of machine to take on the types of complex projects that Custom Mold & Design does. So, they also make unique use of other machine technology across the three companies. For example, Custom Mold & Design uses its five CNC Swiss screw machines to take on all kinds of work, especially work other shops don’t want to do because of the low volume and major setup required. “We don’t use our screw machines like a screw machine shop; we use our screw machines as a tool shop,” Newkirk says. “We use the technology to make tools and tool-related prototypes. We are not trying to be a screw machine shop.”

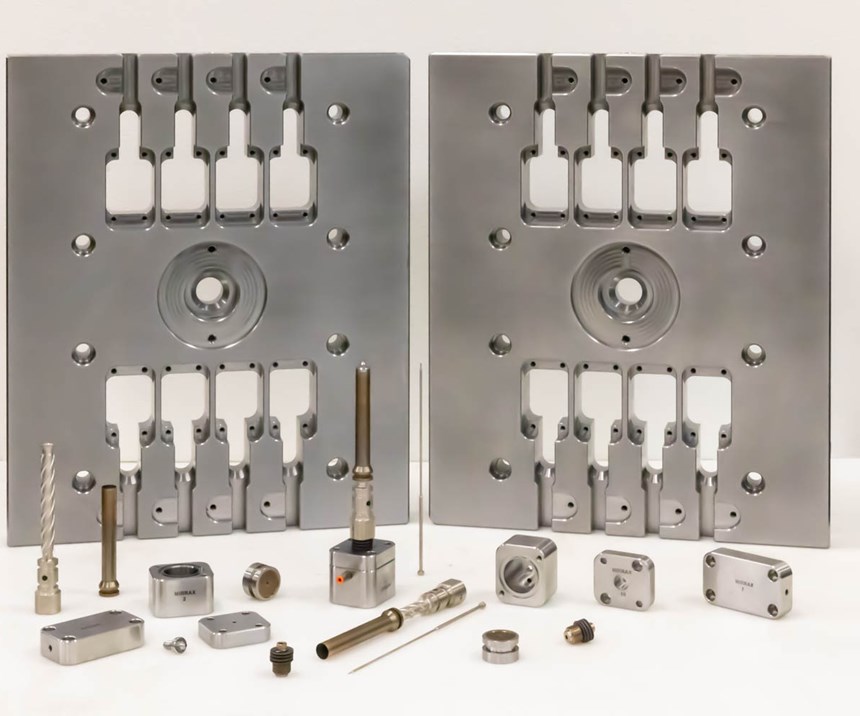

Its new Matsuura MX-850 five-axis machine sees a lot of action also, especially for unique and complex machined parts. The company purchased this machine to expand capacity for the machined component portion of the business. Custom uses two Nakamura-Tome Super NTMX multitasking machines and an NTJ-100 turret type multitasking machine to manufacture mold components, such as drop components for LSR cold decks, mold inserts and cool gate inserts along with precision machined parts. These items drop out of the machine complete.

Custom continues to add hard milling machines (Yasda and Matsuura) and other equipment today as the business and work dictates. Custom Mold & Design is looking at a building expansion this spring to accommodate these equipment additions. Now, with all of this machine technology comes automation, and for Custom Mold & Design, automation is not an afterthought. The shop has eight wire and seven sinker EDMs, some with Erowa robots and two Yasdas and a graphite mill that all have robotic capabilities.

Custom is also going beyond its subtractive roots with a recent partnership and investment in a Matsuura Lumex Avance-25 hybrid metal laser sintering/milling machine for building conformal-cooled inserts and other metal parts. “The best value for us is having the option to use laser and milling together,” Jones says. The machine builds 0.002 inch thick layers of material, 10 layers at a time and then machines. The new improvement of this fifth machine version is a suction system programmed to go around and suck up the unsintered powder in the milling area, after which it comes back and machines, providing much longer cutter life.

Teamvantage, the largest of the three companies, runs the molds and assembles the parts Custom and Paradigme Engineering build. Then there are technology transfer projects for which Teamvantage engineers a system (tool and process) for its customers. For example, a precision mold for Becton Dickinson with a hot runner system complicated by very tight valve gate spacing. Teamvantage developed an automated cell to leak test 100 percent of the parts, assemble them, record data and validate the process. “It's in its own little clean room,” Newkirk says.

Teamvantage houses 26 Sodick Plustech molding machines (60 machines in total). Newkirk believes these are the Yasdas of molding machines because, while other press designs demonstrate variation in part weights, the Sodick Plustech V-Line two-stage injection system molding machine has no check ring and provides extremely accurate shot sizes due to its use of two separate systems to process resin. It uses a screw to melt the resin, and then a plunger is used to very accurately fill the cavity.

Micro molding is another area of expertise at Teamvantage. For example, they work with micro needle arrays that are molded plastic needles used to deliver drugs through the skin, requiring the needles to be very small and sharp so as not to hurt the patient. Teamvantage has developed needle strength and sharpness. Plus, they do a lot of thin-wall parts with high-temperature resins that involve using high pressures to get material into the cavity fast. Teamvantage also conducts mold trials for other mold shops and is constantly adding equipment and capabilities to stay ahead of the competition.

“Making billions of things is boring. We want work for which we can use our engineering and problem-solving capabilities. We are constantly practicing and honing our skill level, so we want customers who need us to do the hard, challenging stuff,” Jones says.

For More Information

Custom Mold & Design

651-757-4000 / custommold.net

763-261-2000 / paradigme.net

651-464-3900 / teamvantage.com

847-439-0201 / yasda.com

877-668-4262 / methodsmachine.com

Matsuura Machinery USA

651-289-9700 / matsuurausa.com

847-490-8130 / plustech-inc.com

Related Content

What’s On the Minds of Medical Mold Builders

Conversations with medical mold builders reveal busy shops, rising automation, digital twins and evolving business strategies amid uncertainty.

Read MoreHow to Use Ultra-Precision Micro Tools, Molding and Automation to Unlock High-Volume Medical Device Miniaturization

Five key areas where a molder/mold builder applies tight-tolerance tooling and advanced molding solutions to enable high-volume production of micro-molded medical parts.

Read MoreStreamlining Medical Device Development With Modular, Risk-Reducing Tooling Strategy

Fast-Track Tooling enables early validation of medical device designs, reduces risks, accelerates time-to-market and ensures alignment with production molds.

Read MoreHow to Improve Your Current Efficiency Rate

An alternative approach to taking on more EDM-intensive work when technology and personnel investment is not an option.

Read MoreRead Next

Overcoming Pain Points in Moldmaking with AI

Shops that embrace AI as a tool, not a threat, can enhance efficiency, preserve expertise, and attract tech-savvy talent.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More.png;maxWidth=728;quality=90)

-02.jpg;maxWidth=300;quality=90)