It’s incredible that Cavalier Tool & Manufacturing is

The Cavalier Army is a 200-strong team celebrating 50 years in business. Source (all images): Cavalier Tool & Manufacturing Ltd.

hitting 50 years, and you’re turning 50 too! How does it feel to share this milestone with the company?

Brian Bendig, President, Cavalier Tool & Manufacturing: The 50th anniversary is both scary and rewarding for me. The thought that I am turning 50 years old and have been doing this for all this time is a little odd to me. Time flies — something that feels like last year was six years ago. But building a strong, recession-proof business with a great reputation? That’s the rewarding part.

Let’s go back to the beginning. Who founded Cavalier, and what got it started?

Bendig: My father, Ray Bendig, started it in 1975 with Rick Janisse and Ron Kellenberger. Dad was the CNC and engineering guy, Rick handled toolmaking and Ron took care of sales and accounting. They came from International Tools Limited (ITL), a large Windsor-based tool shop with approximately 350 employees at the time, primarily working on automotive molds.

Starting as an apprentice in the family business, Brian rose to president, reshaping Cavalier through technology adoption and culture building.

What was the first big project that put Cavalier on the map?

Bendig: It was a Heineken beer display windmill. I still have the prints.

What were the early days like, especially in those first decades?

Bendig: Startups don’t get fancy tech. They used ‘50s and ‘60s machines — old radial drills, hydraulic mills. They had the skills to make it work and eventually bought new tools. When you’re a startup company, you don’t get any of that advanced technology. They started small, then moved to our current facility in 1981, then hit the ‘82-’83 recession. For two years, none of the owners took a paycheck; they focused on just barely covering payroll to ensure employees were still paid. But they grew steadily. By the mid-1990s, significant changes had occurred.

You grew up around manufacturing. How did that shape your path to Cavalier?

Bendig: I grew up in Woodslee, next to my grandfather, a blacksmith inducted into the Agriculture Hall of Fame in 1995. He welded farm gear; my uncle Albert ran Canada’s largest welding shop, building much of the Heinz factory. I was always around metal. In high school, I won five out of six technical awards — I loved auto mechanics and fixing things, but hated drafting. I disassembled and rebuilt carburetors. At 15, I started sweeping Cavalier’s shop to earn a leather coat my dad had promised. That Saturday morning, my bedroom door opens up. He flips the light, kicks the bed and says, “Get up, you’re going to work.”

Time flies — something that feels like last year was six years ago. But building a strong, recession-proof business with a great reputation? That’s the rewarding part.

What was your early impression of the shop?

Bendig: At 15, I didn’t have a measuring stick. I’d been around my grandfather’s forge, but I hadn’t seen enough to judge. I just swept from one corner to the other.

From Ray Bendig’s founding spirit to Brian Bendig’s modern leadership, Cavalier’s success spans generations.

You didn’t stay at first, though. What brought you back?

Bendig: I left to escape my dad’s shadow — sold shelving, then cars, setting a dealership record with 24 in a month. But when Dad got sick with an autoimmune disease and needed a kidney transplant, he called me. He said, “I want you to quit your job. I know you can sell. I want you to leave the dealership and come to Cavalier to sell.”

How did you move into running the show?

Bendig: I traveled extensively, covering 50,000 km a year, visiting shops and gathering ideas. I’d challenge the team — why do it that way? Around 2010, I became general manager. Rick, one of the founders, chose to step down as president and announced, “Effective immediately, I’m promoting Brian as president.” He explained that I had been making many of the key decisions and believed I was the right leader to guide the company forward. By that time, Ron had passed in 1994, and Dad had retired after his illness and passed away 10 years later.

To my team, the Cavalier Army, I'm proud of them. To our suppliers and partners, thank you! We wouldn’t be here without you.

How did you learn the ropes?

Bendig: Planes were my classroom — reading books and articles about CNC, the spine of moldmaking. I always believed that in the mold and die business, the most important part is the CNC. I also visited shops worldwide, learning from places like Portugal, Germany and Japan. What I learned pushed me to adopt advanced technology early, such as high-speed milling.

Taking over in 2008, Brian strategically replaced obsolete equipment, empowered his team and infused a culture of collaboration.

How has Cavalier evolved under your leadership?

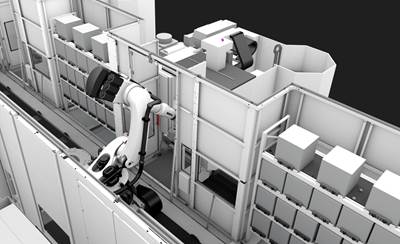

Bendig: We grew from 25 to over 200 people, running five shifts with automation. We focus on speed, building molds faster than competitors. Everyone else says, “I’ll build that in 22 weeks.” I say, “We’ll do it in 16.” We use standard designs and processes to reduce time. New gear, such as the first North American Makino V100S and an Okuma MCR-BV, that increases speed.

How do you balance technology and people?

Bendig: Both matter. We invest in machines like the first Makino V100S in North America for five-axis milling and an Okuma MCR-BV for 2D work. But we also hire young adults with computer skills. I tell tour groups, “You little propeller heads, you kids that are in your basement eating pizza, playing video games eight hours a day. You might have a skill set in engineering or programming.”

What’s your vision for Cavalier in 2030 and beyond?

Bendig: Plastics aren’t going away. We’ll navigate tariffs and changes like we did recessions and COVID. I say, sharpen your tools in slow times to cut faster later. We sell speed and value, not the cheapest price, and we thrive with smaller companies where our expertise truly shines. I’m also thinking molding might be next because customers want parts, not just molds.

What’s the fun part of moldmaking for you?

Bendig: Doing stuff that others can’t. That’s the thrill — beating the clock and delivering what others can’t match.

As you celebrate 50 years, what’s your message to your team and the industry?

Bendig: To my team, the Cavalier Army, I'm proud of them. I'm not always easy. I push for change. When things don't change fast enough, I get nervous. But that's why we're successful.

To our suppliers and partners, thank you! We wouldn’t be here without you.

To the industry, we have to promote what we do. That’s why I’m a big proponent of Manufacturing Day. Open your doors. It’s not burly men and sparks — it’s advanced work. Host open houses, share your story. Each one of us had our “first day”. What hooked us? Share that with the next generation.

Related Content

Collaborative Engineering Drives Quality Mold Solutions

Advanced engineering and tooling teams collaborate to train, design, develop and deliver high-quality, cost-effective molds efficiently, ensuring perfect parts and faster launches.

Read MoreNextGen Mold Technologies is Sticking to the Plan

I caught up with Dennis Goggin, president of NextGen Mold Technologies, to learn how much has changed for this startup mold builder since we last connected.

Read MoreGrowth Requires Mold Builder/Molder to Shift Tooling Focus to Maintenance, Repair and Replacement

The results of aligning awareness and acceptance across departments to balance new tooling and quick response needs.

Read MoreR&D Drives Innovation and Problem-Solving at Michigan Blow Mold Builder

Mid-America Machining focuses on reshaping designs, “right weight" initiatives, continuous improvement and process refinement to enhance moldmaking efficiency.

Read MoreRead Next

2015 Leadtime Leader Awards Winner: Cavalier Tool & Manufacturing - Setting the Pace Holistically

This mold manufacturer has radically transformed its business by instituting a standardized, flexible process, advanced technology and a people-centric philosophy.

Read MoreUsing Automation to Reduce COGS and Stay Globally Competitive

Decade-long, multiphase automation investments lower operating costs and maintain technology lead in an increasingly competitive global market.

Read MoreMMT Chats: Cavalier Tool & Mfg. Talks VR in Mold Design

Join MoldMaking Technology Editorial Director Christina Fuges as she gets the latest news on this mold builder's use of VR for mold design education.

Read More