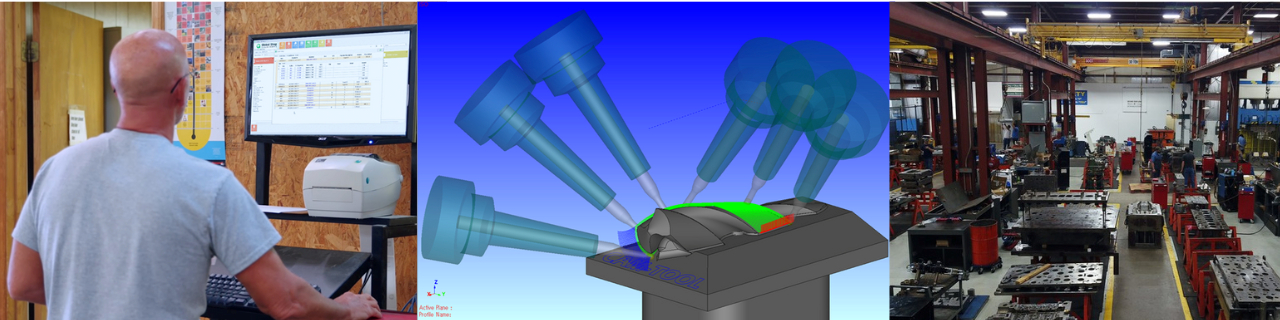

Photo Credit: (top left) Decatur Mold and Engineering, (top right) Global Shop Solutions, (bottom left) CGS North America (CAM-TOOL), (bottom right) Shutterstock

2023 seems to be flying by, we cannot believe it is already March! If February flew by for you like it did for us, you might have missed some of the great content we published. MMT’s Editorial Director, Christina Fuges, had some great MMT Chats covering toolroom efficiency and apprenticeships. We also covered ERP and of course, PTXPO. Here is the list of the top ten most popular MMT articles according to Google analytics.

10. Editorial Advisory Board 2023-2026: Meet New Board Member Isaac Trevino, Best Tool & Engineering

The 2023-2026 version of MoldMaking Technology’s EAB features a new crew of industry professionals. Here’s one of them.

Isaac Trevino, business development manager for Best Tool & Engineering in Clinton Township, Michigan, is one of MMT's new EAB members. Photo Credit: Best Tool & Engineering

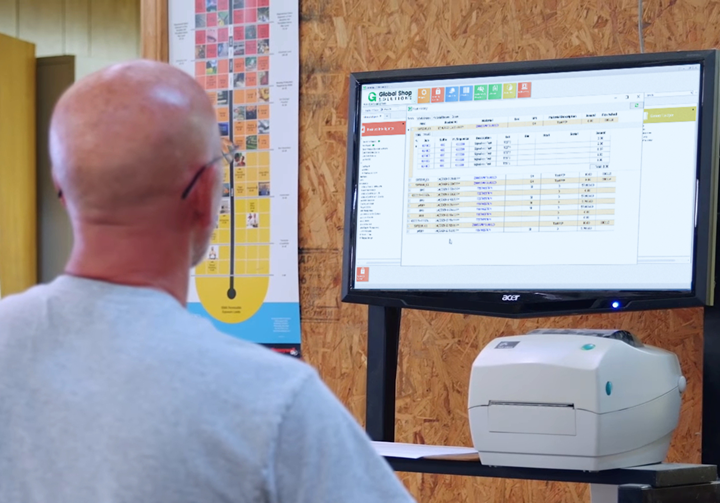

9. The ROI of ERP

Seven reasons why a mold builder needs to invest in enterprise resource planning software and technology.

Efficient, accurate scheduling helps mold builders deliver on time, manage change and meet customer expectations. Photo Credit: Global Shop Solutions

8. PTXPO Preview 2023: 3D Printing, Machining and Cutting Tools Technology and Services

The Moldmaking Pavilion powered by Amerimold is one of seven pavilions returning to PTXPO. Take a moment to familiarize yourself with those exhibitors that can fulfill your 3D printing and machining needs.

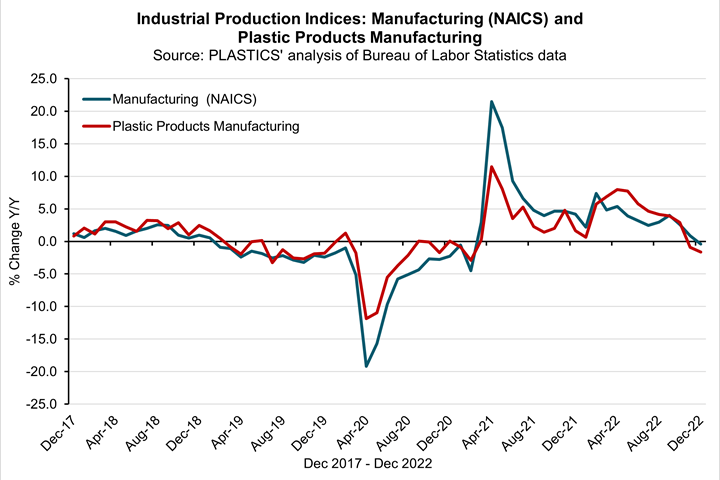

7. Internal and External Factors Continue to Impact U.S. Moldmaking

Sustainable growth remains in the forecast as economic conditions continue to progress.

Industrial Production Indices: Manufacturing total and plastic products manufacturing.

Photo Credit: PLASTICS’ analysis of Bureau of Labor Statistics data

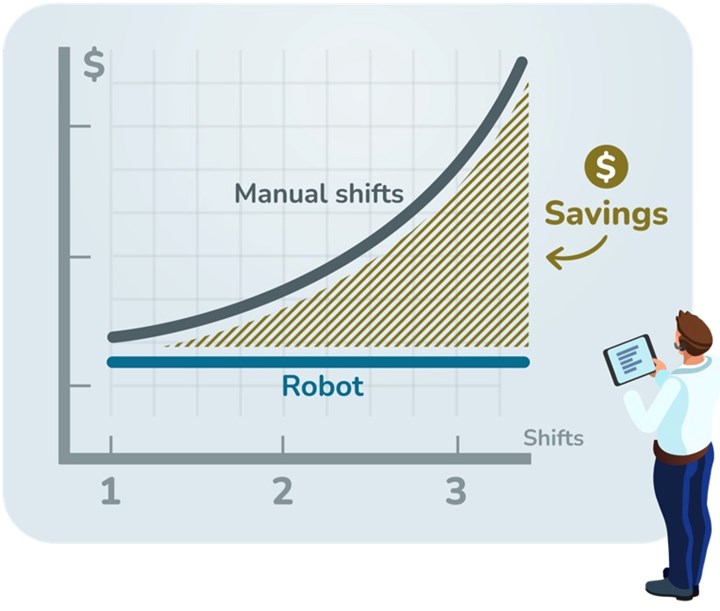

6. Five Strategies to Make Automation Affordable

Mold manufacturers can maintain their competitive edge by making smart capital investments in times of crisis.

Alternative financing options, such as leasing, can give manufacturers a positive return on automation investments from the first day. Photo Credit: HowTo Robot

5. MMT Chats: How to Improve Efficiency in 3 Key Toolroom Areas

MoldMaking Technology Editorial Director Christina Fuges chats with James Jergens, General Manager for Triangle Tool and Penn Erie Tool of The Plastek Group about three simple ways to improve efficiency: tool design, equipment and work in process. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

4. MMT Chats: Mold Design Apprentices Speak Out

Mold Design Apprentices Alex McClinton and Nolan Benedict share their individual journeys to moldmaking, impressions of a unique mold design apprenticeship and their future plans. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

3. MMT Chats: Unique Mold Design Apprenticeship Using Untapped Resources

To help fill his mold design skills gap, Jeff Mertz of Anova Innovations, is focused on high schools and underprivileged school districts, a school that has lower graduation and college entrance rates. The goal is a student-run enterprise. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

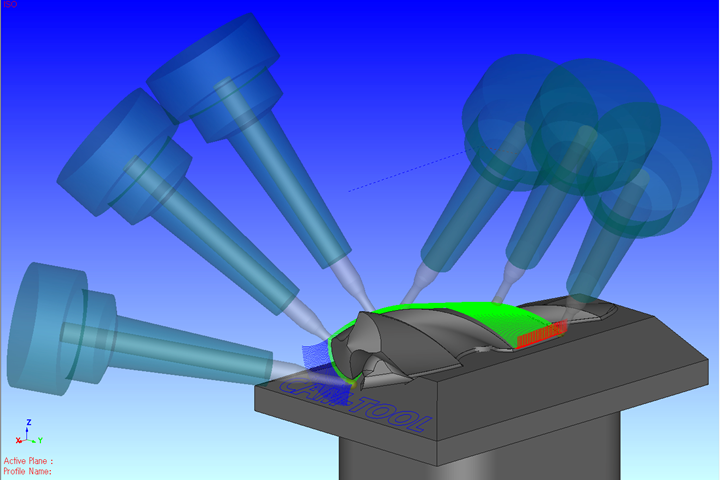

2. How to Generate the Ideal Tool Path for High-Level Accuracy and Finish

When a mold builder can’t compromise part accuracy and surface finish, CAM software with specialized programming strategies is essential.

An example of a complex five-axis toolpath generated around a drill body, showing the control accomplished by using curves to manipulate a toolpath. Photo Credit: CGS North America (CAM-TOOL)

1. Indiana Mold Builder Decatur Mold Offers a History of Grit and a Future of Innovation

Decatur Mold Tool and Engineering Inc. serves as a tooling tour guide, helping busy tooling managers reduce uncertainty, lighten workload.

Decatur Mold specializes injection mold building, quick turnaround prototype builds and emergency repairs. Photo Credit: Decatur Mold and Engineering

Related Content

Mold Innovations Power Unique Auto Lighting Elements on Hummer EVs

Diamond machining, electroforming of micro-optical inserts and modified latch-lock system help injection molds produce unique forward lighting elements.

Read MoreMoldMaking Technology's Most-Viewed Content 2022: Products

MMT shares the five top-viewed technologies, equipment and services of 2022 in each Engineer, Build, Maintain and Manage tenet based on Google Analytics.

Read MoreThe In's and Out's of Ballbar Calibration

This machine tool diagnostic device allows the detection of errors noticeable only while machine tools are in motion.

Read MoreProducts and Services for Multiple Moldmaking Needs

New year, new technology roundup! Featured here is a collection of product offerings, from profile milling cutters to industry-specific CAD/CAM software to innovative hot work tool steels.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

.jpg;maxWidth=300;quality=90)