These thread cores were gear hobbed in-house for a 32-cavity COVID-19 test tube and cap mold package. Photos Credit, all images: Quality Mold Inc.

Who is Quality Mold Inc.?

Corey Bratton, operations manager, Quality Mold Inc.: Quality Mold began as a small, family-owned moldmaking business 37 years ago in a garage with a few manual Bridgeports, grinders and EDMs. It didn’t take long for the shop to start building cap-and-closure molds for Rubbermaid and GE Lighting, which allowed us to expand our capabilities and machinery. Today, Quality Mold remains a privately held plastic injection mold manufacturing company, operating in a 16,000-square-foot facility in Erie, Pennsylvania, just a few miles from Interstates I-90 and I-79, that employs more than 30 trained professionals.

We design and build multiple style tools from prototype to production, such as servo and hydraulic unscrewing, two-shot, stack, and hydraulic and mechanical core pull tools. We mainly produce Class 101 tooling for the medical, consumer and automotive industries. Most of these molds use modern hot gating systems to reduce customer cycle time and decrease scrap.

In 2019, we doubled our manufacturing footprint while maintaining our family values and structure. This expansion gave us a dedicated mold assembly area and a place to relocate our soft mill and lathe departments to make room for additional machines. Before this expansion, we used our garage for assembly and could not access our machines via forklift to load heavier workpieces.

Quality Plastics samples Quality Mold tooling, proves out and processes molds before shipment and can run full production upon a customer’s request.

Our sister company, Quality Plastics, was launched in 1995, specializing in GE Lighting production and serving as a sample house for Quality Mold. As the industry changed, we became ISO 9001:2015 certified to accommodate customer needs. Quality Plastics has been running as a sample facility and a place for customers to run production and automation. iT currently has 15 injection molding machines ranging from 25 to 300 tons. Of these 15 machines, we have purchased four new Sumitomo presses ranging from 60 to 140 tons which allows for better process information for the end user. In addition, our knowledgeable processors have experience with a large selection of engineered and commodity resins, giving our customers dependable data.

What do you view as your chief competitive advantage?

Bratton: Our quality of work, ability to adapt to the changing industry and honesty with our customers. This takes the right people with the right experience and attitude. Approximately 70% of our shop employees completed a manufacturing apprenticeship program before finding long-term employment at our facility. Our experienced moldmakers then provide in-house training for the younger employees.

We are committed to continuous improvement, quality and growth. As a result, we restructured our management team to include a designated sales manager/quoter, operations manager and project manager, resulting in better tracking of a project across the shop floor and better planning for future jobs.

Our team’s in-depth knowledge and experience with unscrewing molds is a crucial differentiator.

Quality Mold uses its Yasda to machine mold base plates for a 32-cavity syringe mold.

Share an example of a recent change in your use of technology.

Bratton: In 2020, we purchased two new Mitsubishi wires and a mid-sized Yasda jig-boring machine. In 2021, we purchased a new Mitsubishi sinker EDM, a Roku Roku hard mill and a 10-inch chuck Hwacheon lathe (a sister to our large 12-inch chuck Hwacheon lathe).

Then last year, we purchased a large OKK mold base mill and a second Zeiss coordinate measuring machine (CMM). Over the last few years, we added five new surface grinders (Okamoto) and two CNC wet grinders (Supertec and Amada). We plan to update more machinery during the next few years.

In addition, we started using project tracking software, allowing the shopfloor employees to send an alert when components are complete. This approach gives us a live feed of the progress of any mold build or repair project throughout the shop.

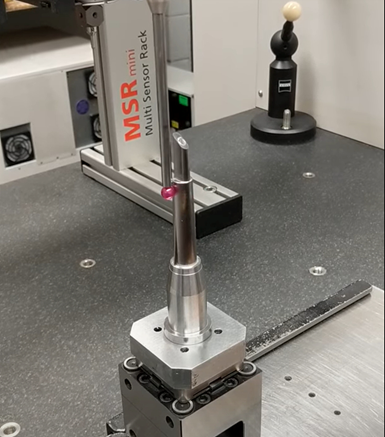

Mold inspection by hand, eye and a robotic probe is a specific investment area.

Using a Zeiss Contura G2 CMM, Quality Mold inspects all areas of the mold and gives customers reports for critical areas. Here, the system is scanning to take precise measurements of mold components.

Can you explain?

Bratton: All plastic injection molds designed and constructed by Quality Mold undergo a thorough inspection. Every piece is inspected by hand and a Zeiss Contura G2 CMM uses microscopic robotic probes to survey the inner and outer surfaces of the mold cavities. Once the mold is inspected correctly, we send it for optional sampling at the Quality Plastics facility, offering another level of assurance that a mold will function properly and produce the best quality products.

We have also recently added an additional Zeiss DuraMax on the floor so toolmakers can check parts during machining and while the G2 is inspecting critical final dimensions. We can now move more parts through inspection as they are not being interrupted for machining checks.

What is an example of the most significant recent change in your general approach to business?

Bratton: Within the last six months, we restructured our management team. We now have a dedicated operations manager who distributes incoming work and manages the jobs on the floor. In addition, we have a newly appointed quoter who works with the management team to review costs and delivery dates. We also have a new project manager who sources software and updates our standard operating procedures.

These changes have improved workflow through the shop from first contact to the product leaving the building. This new management style has also improved department communication, which has improved employee morale too.

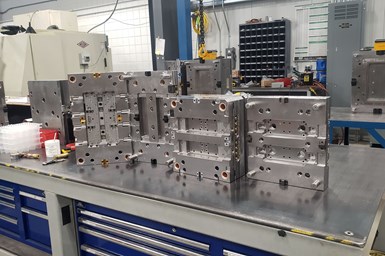

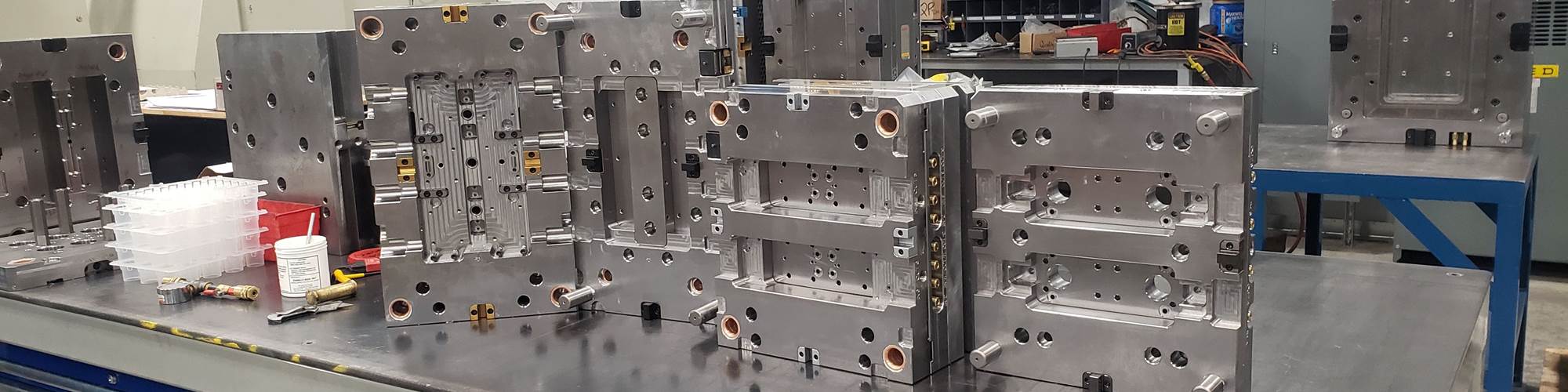

Multiple injection molds remain in various stages of assembly in Quality Mold’s new assembly department.

How will the business evolve in the next three to five years?

Bratton: We will continue to invest in technology to maintain our quality of work. We added Autodesk Moldflow software to our in-house capabilities, which analyzes the best gate location and identifies potential problems before the mold is manufactured. In addition, we plan to add a laser welder to our portfolio for minor repairs, avoiding the challenges with external schedules. We are also working with a few customers on 3D-printed metal cavities and considering some in-house technology to 3D print plastic parts that will assist customers through the design process.

We will expand our customer base and bring in more design-build-run tooling by capitalizing on our team’s knowledge in compression molding, stack molding, cube molding and rotating platen molding.

We will also increase our exposure to the industry by participating in more manufacturing and plastics trade events and focusing on marketing — mainly improving our social media presence to promote our capabilities and technology.

Quality Mold designs and builds mainly Class 101 prototype to production molds for the medical, consumer and automotive industries.

Tell us how you are addressing the skills gap in the industry.

Bratton: Quality Mold is currently well-staffed with around 30 employees, seven of whom have been with the company since its early days. Another 15 of these employees have 10-30 years of experience across all areas of injection moldmaking.

However, as with most companies, we are always looking for additional employees to grow with us. We accept applications on an ongoing basis from experienced moldmakers looking to move from a corporate-owned company workforce to a family-run environment. In addition, we regularly seek out young, promising talent for hands-on training by our experienced staff. Over 25% of our employees are under the age of 30. Most applicants are referred by current employees or through connections made on social media platforms.

Describe the most notable mold project your company was awarded.

Bratton: We were deemed an “essential” business throughout the pandemic, so we never shut down.

During this time, our team came together and worked long hours and weekends to help complete several COVID-related mold projects that required rushed delivery times.

We had three customers who needed plastic injection molds built for products and equipment for virus testing, treatment and vaccination. We also built two components into the new testing machine for COVID rapid testing and tooling for test tubes, caps, PCR tubes and plungers, all related to the COVID-19 outbreak.

Related Content

Lights-Out Metal 3D Printer Minimizes EDM Needs for Moldmakers

The Matsuura LUMEX series boasts both forming and milling capabilities in one unit, achieving highly accurate mold component production, with the ablity to integrate conformal cooling and porous venting.

Read More3D Printing Technologies for Moldmaking Applications

3D printing technologies, from conformal cooling to complex mold building, are making an impact on the moldmaking industry, one innovation at a time.

Read MoreVIDEO: How can 3D Printed Tooling Improve Injection Mold Venting?

Proper venting is one of a mold builders toughest challenges as molders struggle to keep vents free flowing in production. Learn how to apply 3D printing to mold venting and the benefits of additive venting inserts.

Read MoreA 3D Printing Retrospective

A personal review of the evolution of 3D printing in moldmaking throughout the past 25 years.

Read MoreRead Next

Indiana Mold Builder Decatur Mold Offers a History of Grit and a Future of Innovation

Decatur Mold Tool and Engineering Inc. serves as a tooling tour guide, helping busy tooling managers reduce uncertainty, lighten workload.

Read MoreMidgard Inc. Tackles Tooling Challenges and Automates Production to Keep Molds Running

This Eastern Pennsylvania molder does cavity changes daily, making its in-house toolroom critical to quickly fixing mold problems.

Read MoreNext-Generation Thinkers Redefine Moldmaking Quality and Service

Canada-based NextGen Mold Technologies is a new mold shop using excitement and empowerment to encourage better ideas every day.

Read More.jpg;maxWidth=970;quality=90)

.png;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)