Midgard Inc.’s Engineering Manager Hugh Rush and Marketing Manager Andrew Brown are focused on expanding, diversifying and automating as they look to the future. Photo Credit, all images: MoldMaking Technology

What’s in the company name?

Hugh Rush, Engineering Manager: The name is not related to the family or plastics, but it is memorable and the name that the founders chose. From what we understand, “Midgard” is from Norse mythology and means “halfway between heaven and hell where gentlemen meet.”

Share a little about the company's history.

Andrew Brown, Marketing Manager: The parking lot used to be my grandparents’ house. In 1947, when my grandfather, Elwood (Woody) Brown, retired from the Army Air Corp., the property became a tool and die shop. Then in 1955, he officially founded Midgard and pivoted toward injection molding with a couple of small machines.

U.S. Gauge was making glass lenses and Woody believed he could do it out of plastic. So he and his tool designer, Harry Hoff, designed and built a tool and took it over to Van Dorn’s facility to run the parts at night to find a solution. Eventually, he made enough money to purchase his first press, a Van Dorn. Our current breakroom was the original molding room. Over the next 67 years, we expanded the facility incrementally.

Today we have 56 employees. Before 2008, we had around 100 employees, but since then, we’ve advanced and automated some aspects of production that reduced the need for manual labor. We keep more presses running now with fewer people.

What type of work does Midgard specialize in?

Rush: We work with customers from design to processing parts, but our specialty is injection molding across many industries. We’re all over the place — from toothbrushes to missile grommets. We like to say that we do a little bit of everything, including bottle caps, flashlights, mini weather systems and nautical bullhorns. We are more into engineering-grade plastics, but we do handle some commodity resins.

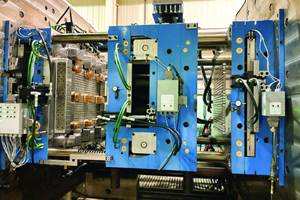

Midgard’s injection molding facilities are located in Green Lane, Pennsylvania, and Lake Wales, Florida. Each employee is continuously trained to maintain the utmost standards, with all production steps subjected to continuous quality monitoring.

We produce custom-designed and high-quality components in two modern facilities located in Pennsylvania and Florida. We mold all engineering-grade resins as well as commodity-grade materials. We go from 50 pieces to sometimes millions of parts. We offer a full range of press sizes — from 30 tons to 725 tons and shot sizes from 0.1 to 95 ounces.

With over six decades of experience in plastics engineering, we can assist with part design to better moldability and tooling recommendations. Our team is committed to tweaking part designs for manufacturing because the job can’t get done if you don’t design a part for manufacturing. It’s never going to happen. We use 3D modeling, Solid Works, AutoCAD and Mastercam coupled with the high-speed capabilities of our CAM department to shorten our mold lead times. We employ concept 3D printing to assure quality and accuracy before moving to full production. We use Moldflow software to verify fill and proper gate location and outsource advanced mold flow analysis (including warp and critical dimension stability).

Customers come to us because we’ll make it work. That’s our service mentality. We’ve even had customers leave us for price only to return because they missed our service level.

How vital is moldmaking at Midgard?

Midgard focuses on simple to complex projects that include engineering, mold design and building, molding and a full complement of secondary operations.

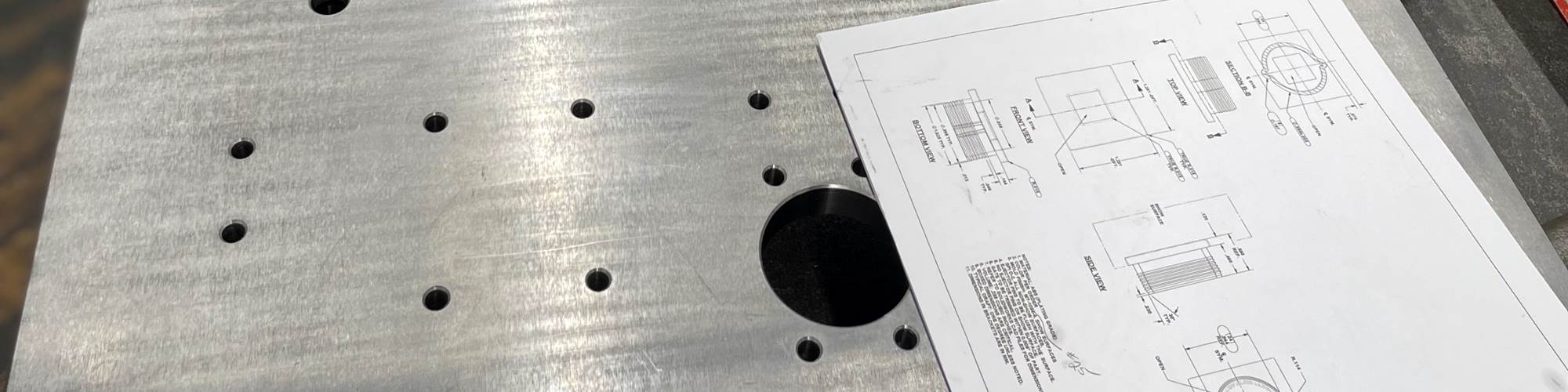

Rush: We specialize in complex, high-detail and critical-dimension moldmaking using various steel and aluminum grades for short-to-medium production runs, so having an experienced in-house toolroom is so important. Plus, our molds are like Swiss Army knives — we have one tool, but it makes 10 parts. We have drawers, bins and cabinets full of inserts for swapping out because we are doing cavity changes every day.

Most customers ask if we have our own tool shop because they like knowing that we can fix it quickly if something goes wrong with the mold. Even though we do not perform a lot of mold building in-house, we are hyper-focused on supporting production. This goal only emphasizes the need for experienced moldmakers because if a mold goes down and the customer needs product tomorrow, we must get that mold back in the press as soon as possible.

Skilled toolroom personnel, like Chris DeAngeles (right), and fast, accurate machining equipment enable Midgard to provide fast and precise tooling with swift project turnaround at competitive prices.

Our toolroom team is experienced in injection mold manufacturing using equipment such as Makino vertical machining centers, Fanuc wire EDM, high-speed EDM drills and sinker EDM. This in-house tooling capability allows us to provide quick tool modifications, easy component prototyping and virtually no downtime when repairs are necessary.

Our team is committed to tweaking part designs for manufacturing because the job can’t get done if you don’t design a part for manufacturing.

How have you applied automation?

Brown: Our use of robotics and special fixtures help to improve production efficiencies; vertical rotary tables improve production efficiency for insert molding or overmolding, and our collaborative robotics and our Industry 4.0 real-time resource management system work together to improve efficiency and consistency in our processes and product.

We invested in robots and vision systems to run some projects fully automatic. For one particular job involving a ventilator system nut, we were breaking too many $3,000 cores. The job required a servo-driven de-threader that runs off a program. We have cores attached to a servo motor that tapers the inlet, so we mounted a camera to a robot with a red LED light shining underneath as the camera takes a photo every time the mold opens.

The vision system is tricky. We’ve had to refine a lot to improve repeatability and catch all flaws. For example, even a piece of dust will catch and hold up the process, so this camera takes a picture, sends an alarm to the machine and then figures out what happened. It also looks for short shots and anything that will be hung up.

Can we get more details about your new vision/camera system?

Edwin Arroyo, Quality Manager: We are committed to quality assurance and continuous quality improvement, which involves four trained and highly skilled inspectors and technology. Our goal is to prevent problems before they arise.

Midgard retains first and last parts to assure quality from lot to lot. Its inspection department is fully equipped with the latest mechanical measuring devices and supporting software to provide for accurate and repeatable dimensional checks, such as this Keyence camera system.

We recently purchased a Keyence camera system for our quality department. It offers fully automated optical part measurement. This technology will detect abnormalities earlier in the process, so we can be much more proactive in solving part problems and making adjustments.

It detects any out-of-tolerance dimensions. You can place up to 100 parts on the machine and each part can have up to 300 dimensions and the scanner will check them within minutes. It tells you which parts are bad and which dimensions are bad.

I have been making measurements for an assembled piece for the quality team, so they can practice. I wrote a program, set up the parameters and tolerances, then programmed the machine. Then the machine takes all the measurements for you. It really speeds up the process. We have hundreds of instruments, so this machine will have the measurements done by the time you just locate the instrument. We had a simple program complete on delivery day, and first and second shift inspectors quickly learned to write programs.

Our machine is the IM-8000 Series Image Dimension Measurement System. It is capable of high-definition imaging and has triple the detection performance of conventional systems and simple operation. You just place the part on the stage and press one button. A 20-megapixel CMOS (Complementary Metal Oxide Semiconductor) sensor and a new algorithm for stable edge detection make the high-accuracy measurements on up to 300 features within seconds possible.

We are looking to train and qualify operators at various levels in the long term. For example, an “A” level operator would be qualified to work on a press or another specific type of equipment at the press, such as this camera system.

What are some other key product and equipment investments?

Rush: We have some key technology in our mold building and maintenance areas:

Midgard’s Makino F5 vertical machining center provides stiffness and rigidity for chatter-free cutting of small details and fine features when using small tools at high rpm.

Makino high-speed mills have taken us from mostly EDM for our hardened blocks to fully CNC machining. We get cavities from this mill with ready-to-go surface finishes, which has saved us quite a bit of time at the end of the build as no polishing is required.

We just purchased a new Makino with four-axis milling capabilities and technology to help reduce the time needed for setup and milling.

Our Die Sep mold separator has been a great addition to the shop as we no longer struggle to open molds. For example, our cavity changing process used to take two guys maneuvering larger molds. Using the mold separator, one guy can tip a mold half to work on cavity changes, which is more efficient and safer. In addition, it puts less physical strain on the shop employees that work on molds.

And our Cold Jet dry ice cleaner works well on cleaning molds without any physical contact, which means less wear on the mold. We run a lot of high-temperature materials, so molds are usually hot when they need cleaning during a run and this system works the best on hot surfaces.

Also, many of our molds require regular cleaning during a run because of gassing and clogged vents that result in short shots, and this system allows production personnel to clean molds in the press easily. This system provides a quick and effective way to keep things running smoothly.

You foster a culture of curiosity. What does that mean?

Brown: We encourage everyone to ask questions, and we reward curiosity with training that can lead to career advancement. For example, when we’re bringing someone young into the company, we emphasize the automation we currently have running and offer free online classes if they are interested in creating a foundation in robotics — how to use robots, how they interact with the press, etc.

Right now, we are setting up a workshop with a dummy machine so that interested employees can play around with the robot. Then they can combine the hands-on exercises with Universal Robots Academy, which offers a variety of modules.

Most customers ask if we have our own tool shop because they like knowing that if something goes wrong with the mold, we can fix it and quickly.

These robots are so approachable, and the programming goes step by step. It lines up everything like “this arm moves to this axis at this point in the cycle.” The user can also visually see the robot’s cues from the machine because everything is hardwired. Plus, instructions are all in layman’s terms so that anyone can approach the robot. There is not a lot of jargon that will be lost on someone new to robotics.

What is Midgard's marketing strategy?

Brown: We’ve recently started to improve our presence on Facebook and LinkedIn and increased our outbound marketing efforts. For example, we are looking at our organic search content (keywords and metadata) and started using a tool called SEM Rush, which has been terrific for analyzing our site and identifying areas of improvement. We’ve also added an aerial drone video of the facility to our website.

What are you focusing on in the next few years?

Rush: We’ve grown quite a bit and want to continue growing by diversifying our customer base and investing in more robots (one on every press). Production equipment is where we make our money, so we will focus on technology like robots to improve quality, offering better consistency and repeatability.

Brown: The most common thing I hear during employee exit interviews is that people are driven crazy by repeatedly performing the same task or routine — manning one particular machine, making one part or doing press-side assembly. People say it’s too monotonous. As a result, we are working toward more robots, so instead of an employee being engaged with only one job, they can engage with four different jobs. These robots will also address ergonomic issues and remove repetitive motions, yielding less fatigue.

We are always looking to expand with more machines and more business!

Related Content

Non-profit Organization Advances Diversity and Inclusion Initiatives in Manufacturing to Fill Skills Gap

Build A Dream delivers programs to inspire young women, providing confidence and filling the skills gap by collaborating with speakers, community leaders and businesses.

Read MoreDesign Strategy Tackles Big and Small Complexity Challenges for Southeastern Mold Builder

Delta Mold Inc.’s core values, engineering expertise, five-axis machines and molding capabilities help the team turn a proposal into a manufactured mold or part with custom design, finishing and assembly.

Read MoreFather/Daughter Team Takes Mold Business into the Future

Innovation, personalized service and a team’s collective mold manufacturing experience earn customer loyalty for 56 years and set the business up for future success.

Read MoreHigh-Technology, Diversified Mold Builder Has Its Eye on Improvement

Commitment, engineering expertise, flexibility, quality and customer service help Wisconsin moldmaker Triangle Tool LLC discover ways to grow and build molds faster.

Read MoreRead Next

Strategically Located Mold Builder Offers Precise Tooling and Molding

This small family-owned U.S./Mexico mold builder moved to the next level of precision with next-generation technology investment.

Read MoreMold Builder Uses Counter-Intuitive Approach for Mold Challenges

Matrix Tool Inc. answers customers’ hard questions with creative solutions for cavity spacing, tool sizing, runner layout and melt delivery that reveal the benefits of running in a smaller press size at lower cavitation but higher yield.

Read MoreTop Grade Molds Is All About Innovation and Collaboration

Top Grade Molds develops technology solutions with a heavy emphasis on R&D, recyclable material trends and collaboration.

Read More

.jpg;maxWidth=300;quality=90)

_300x250 3.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)