Photo Credit, clockwise from top left: 3D Systems, Hexagon, DMG MORI, AddUp

Ever-evolving technological markets continue to positively influence and impact the manufacturing industry. As additive manufacturing (AM) has risen in popularity, mold builders, for example, have seen a difference in what it can provide, from more intricate conformal cooling channels, to mold repair and production of complex components. To help readers keep up with the different products and services that impact moldmaking, MMT is here with another monthly technology roundup, providing readers with a rundown of relevant technology on the market.

This month’s focus is on AM products, processes and equipment. To check out more tech roundups from months prior, browse the “New Tech” section of the MoldMaking Technology website or look up “technology roundup” in the homepage’s Search bar. To learn more about a specific product featured below, click the link in the respective product’s title.

To read more content about 3D printing in moldmaking, visit the Additive Manufacturing zone page.

Additive Manufacturing

3D Systems’ large-format Atlas pellet extrusion 3D printers utilize affordable and high-performance thermoplastic pellet feedstocks for 3D printing medium- to large-sized tooling and molds for thermoforming and vacuum forming applications. Printing directly with thermoplastic pellets offers several advantages as an additive manufacturing (AM) method, especially when it comes to reducing part costs and increasing print speeds, according to the company.

Photo Credit: Hybrid Manufacturing Technologies

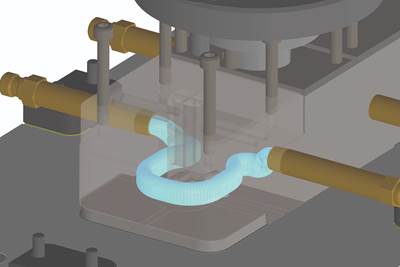

Hybrid Manufacturing Technologies develops technological solutions that combine additive deposition, subtractive and inspection technologies, marrying the freedoms of additive manufacturing (AM) with the precision of CNC machining so that laser welding and finishing of molds be can achieved in the same setup. Introduction of a new internal cladding head called the Ambit Flex 22i makes these capabilities possible. Available as a retrofit for existing CNC machines or for direct integration into new machines, the cladding head system provides users improved access for the additive deposition head to access difficult-to-reach areas of the mold that need metal added.

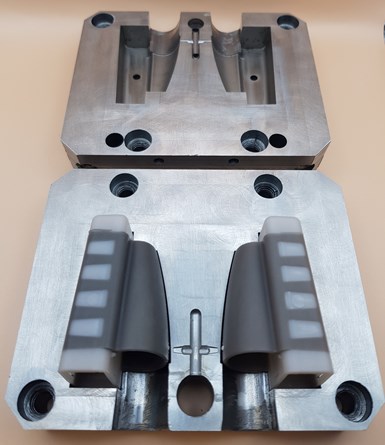

3D-printed mold slide for plastic injection molding. Photo Credit: AddUp Inc.

The FormUp 350 from AddUp is a multi-laser metal AM system, with a 350 × 350 mm build surface, ideal for tooling applications. AddUp’s proprietary roller technology delivers reduced supports and optimal surface finish, providing solutions to manufacturers looking to maximize quality, productivity and ROI. According to the company, it is also capable of meeting mechanical and geometric properties (up to 0.1 mm dimensional accuracy) and material density, and can be used for all types of metal powders, even reactive ones. A laser accuracy of 35µm is achieved.

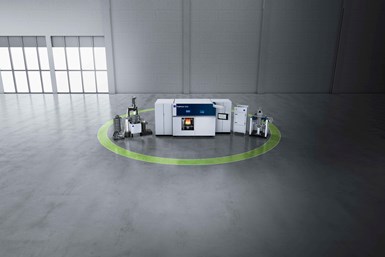

Photo Credit: DMG MORI USA

DMG MORI’s Lasertec 65 DED hybrid machine, which combines additive manufacturing (AM) with milling capabilities, provides many opportunities for mold and die repair, as well as the manufacture of new molds. Due to the system’s hybrid capabilities, DMG MORI notes that conformal cooling without any straight drilling and sealing points can be achieved. The powder material is switched in each layer to coat the copper core with tool steel. The result is a die-cast mold with the same tool life as the original part and significantly improved tool performance and quality.

Mold and mold base for gas cap applications with cooling channels shaped to be close to the part in the snaking part (tilted within the block). These cooling channels cannot be drilled, making additive manufacturing essential. Photo Credit: Oak Ridge National Laboratory

Open Mind Technologies, a developer of CAD/CAM software solutions worldwide, offers hyperMILL Additive Manufacturing which has a wide range of capabilities for additive and hybrid processes, including the ability to create additive tool paths from all available toolpath strategies. This functionality is said to be exceptionally productive for directed energy deposition (DED) processes for additive/hybrid manufacturing in a multi-axis machining or robot delivery system setup.

Photo Credit: Edro Engineering and Specialty Steels

Edro Engineering and Specialty Steels, an exclusive distributor of Bohler tool steels, highlights Bohler M789 AMPO, a newly developed maraging stainless steel powder designed for additive manufacturing (AM) applications. Bohler M789 AMPO combines the mechanical properties of maraging 300 steel with the corrosion resistance of 17-4 PH stainless steel.

The Meltio M450 is a turnkey directed energy deposition (DED) solution that integrates wire dispensing technology on a three-axis Cartesian system in a closed enclosure. Reliable and inexpensive, the company says it is the machine suitable for additive metal manufacturing of medium parts and molds.

Addifab has plugged 3D printing speed and design freedom directly into tool designer workflow, to enable a rewriting of the pilot tooling playbook. Soluble, 3D-printed injection mold cores and cavities is one of the essential innovations behind the novel Addifab freeform injection molding (FIM). According to the company, these cores and cavities are based on a new class of proprietary 3D printing resins that combine high strength and thermal stability.

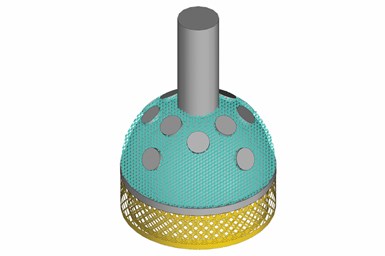

ESPRIT CAM software introduced by Hexagon’s Manufacturing Intelligence division now offers users the digital tools needed to prepare 3D-printed components for manufacturing using powder bed fusion (PBF) technologies. Because hybrid manufacturing entails performing both additive and subtractive processes, Hexagon notes, integrating build preparation tools within CAM software streamlines workflows per part and offers efficiency improvements when scaling up additive manufacturing (AM) volumes.

The Trumpf TruPrint 5000, a highly productive, automated metal 3D printing machine, is said to create new possibilities for the tool and die making industry as a result of its preheating capabilities. Previously, toolmakers could not 3D print carbon tool steel, as the material often cracked when returning to room temperature after laser processing. Now, Trumpf says, the TruPrint 5000 3D printer can be preheated to 500ºC (932ºF), which reduces the temperature drop following laser melting and significantly improves material and surface quality of carbon steels.

.jpg;maxWidth=970;quality=90)

.png;maxWidth=300;quality=90)

_300x250 4.png;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)

_970x250 3.png;maxWidth=970;quality=90)