Maraging Stainless Steel Powder Engineered for Additive Manufacturing Applications

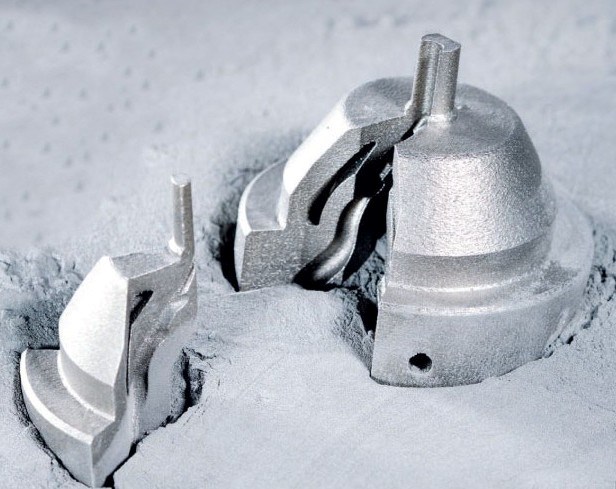

Bohler M789 AMPO, introduced by Edro Engineering, is well suited for conformal cooling inserts, or applications where high hardness and corrosion resistance is required.

Photo Credit: Edro Engineering and Specialty Steels LLC

Edro Engineering and Specialty Steels, an exclusive distributor of Bohler tool steels, highlights Bohler M789 AMPO, a newly developed maraging stainless steel powder designed for additive manufacturing (AM) applications.

Bohler M789 AMPO combines the mechanical properties of maraging 300 steel with the corrosion resistance of 17-4 PH stainless steel. Edro says the patented grade can be easily printed without preheating and can achieve a high hardness of 52 HRC with easy heat treatment. Bohler M789 AMPO also has excellent polishability which makes it the ideal choice for conformal cooling inserts in plastic injection molding and in any other application where high hardness and corrosion resistance is required.

For more information please visit Edro.com.

Related Content

-

Products and Services for Multiple Moldmaking Needs

New year, new technology roundup! Featured here is a collection of product offerings, from profile milling cutters to industry-specific CAD/CAM software to innovative hot work tool steels.

-

Technology Roundup: Additive Manufacturing, Mold Materials

Upgrade your manufacturing process or tool steel choices with new/improved additive manufacturing and mold material innovations from AddUp Inc., Mantle, Next Chapter Manufacturing, Edro and more.

-

From Injection Mold Venting to Runnerless Micro Molds: MMT's Top-Viewed June Content

The MoldMaking Technology team has compiled a list of the top-viewed June content based on analytics. This month, we covered an array of topics including injection mold venting, business strategies and runnerless micro molds. Take a look at what you might have missed!

.jpg;maxWidth=300;quality=90)