ESSENTIAL READING

VIEW ALLHow to Produce More Accurate Molds and Reduce Rework

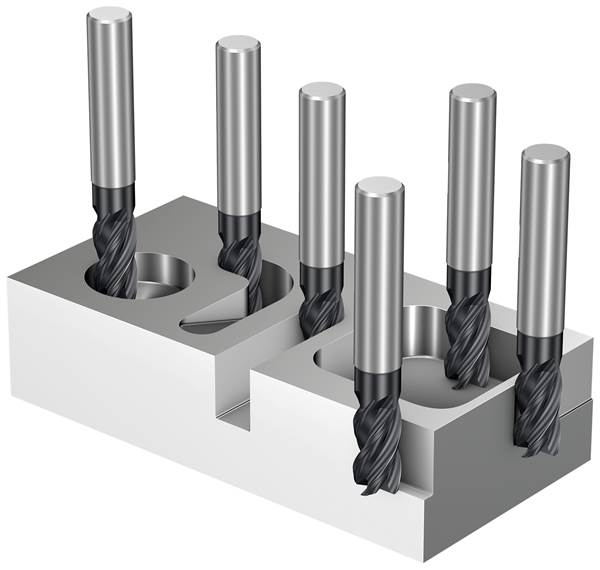

Patented micro-milling process for manufacturing steel plate flat and parallel helps mold builders shorten mold build times and increase accuracy.

Read MoreLaser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

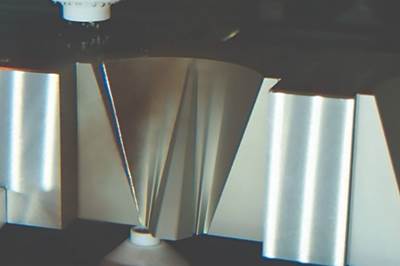

Read MoreSoft Wired: Cutting High Taper Angles with Wire EDM

Examine the wire’s properties to determine the right one for achieving the best cut.

Read MoreHow to Use Diffusion Bonding to Optimize a Mold’s Thermal Performance

Joining dissimilar metals has tremendous potential for conformal cooling, but to successfully use diffusion bonding, a mold builder must understand the complexities of the interface and its effect on the chemical and thermo-mechanical properties of the bond.

Read MoreHow to Eliminate Streaks and Weld Problems with Laser Technology

Laser technology overcomes streaking and welding challenges for new mold textures and texture repair.

Read MoreHow to Lower Cycle Times With the Right Tool Steel

Combining excellent mechanical properties, high wear resistance and high thermal conductivity in a specialty tool steel yields cycle time reduction.

Read MoreLatest Mold Materials News And Updates

Xact Metal, Uddeholm Partner to Offer Corrax Tool Steel Powder

Moldmakers and molders will have access to a mold steel capable of an A1 surface finish post-polishing, supporting the industry’s expansion into metal 3D printing.

Read MoreCorrosion-Resistant Mold Steel Designed For Polishability

NPE2024: Uddeholm showcases its Tyrax ESR mold steel that combines toughness, corrosion and wear resistance.

Read MoreTight-Tolerance, 100% Recyclable Steel Plate Processing

Steel 21 strives to make mold builders more efficient with flat, parallel and more sustainable steel plate grades for plastic injection and compression molds.

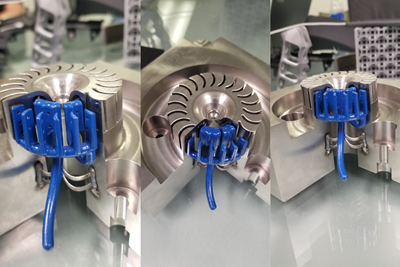

Read MoreSintered, Porous Mold Steel Eliminates Gas Buildup

Molder’s World highlights its acclaimed Vortex self-venting mold steel, which uses a system of microscopic, interconnected pores to optimize molding processes.

Read MoreEllwood Specialty Steel Becomes Ellwood Specialty Metals

Integrated producer of tool steel adds Ellwood Aluminum cast house into the Ellwood family of companies to serve both metal needs.

Read MoreHow is an Aluminum Mold Energy-Efficient?

Nine ways aluminum molds save energy and production costs.

Read MoreFeatured Posts

MoldMaking Technology's Hottest Tips of 2023

The staff at MoldMaking Technology prides ourselves on bringing you the most helpful, relevant tips in the industry. Here are the top five most-viewed tips of 2023 based on Google Analytics.

Read MoreFive Benefits of Aluminum Tooling

Aluminum molds are worth a second look as a viable means to swiftly and cost-effectively get products to market.

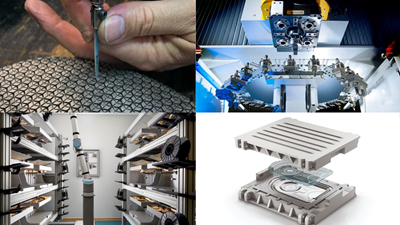

Read MoreMoldmaking-Related Technology Highlights

This month’s tech roundup highlights mold materials and other miscellaneous technologies for moldmaking needs.

Read MoreHow to Select the Right Tool Steel for Mold Cavities

With cavity steel or alloy selection, there are many variables that can dictate the best option for moldmaking.

Read MoreTechnology and Sourcing Guide 2023: Mold Materials

Proper selection of the appropriate mold material is critical to manufacturing a high-quality mold. Tool steel, aluminum, copper and alloys are some of the materials used.

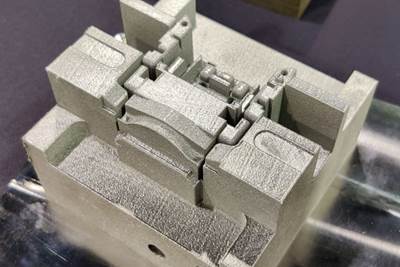

Read MoreLarge Hybrid Steel Insert Solves Deformation, Dimensionality, Cycle Time Problems

DMLS printers using metal additive powders selected by Linear AMS to produce high-quality, accurate, consistent 3D-printed mold components with certification and traceability.

Read MoreFAQ: Mold Materials

What are the benefits of alloying tool steel?

Steels with a chromium content of at least 12% are generally considered corrosion-resistant. Martensitic tool steels have a high chromium content of 16% and a carbon content between 0.33%-0.38% that provides quenching and tempering during which only tempering carbides appear in the microstructure, leaving behind enough chromium to ensure corrosion resistance.

The resistance to corrosion is based on the formation of surface layers, protecting the metal from further reaction with oxygen. The most effective element is chromium. In combination with oxygen, it forms an oxide layer (chemical configuration: Cr2O3) on the surface, which shows a dense and amorphous structure as the chromium content increases. The formation of this Cr2O3 surface layer of approximately one nanometer promotes passivation, a process that protects the material against surface corrosion and ensures the functionality of the mold.

Alloying with molybdenum improves resistance to pitting corrosion, as it contributes to stabilizing the passivating Cr2O3 layer. In addition, molybdenum builds into the structure of the layer and strengthens it by preventing the removal of oxygen from the respective layer. Using stainless steels alloyed with molybdenum can also avoid corrosive attacks during mold cleaning, preventing hazardous products from entering the production process.

(Source: The Benefits of Alloying Tool Steel)

How can moldmakers optimize the quality of recycled plastic for molds?

The successful use of recycled materials in injection molding depends on how the original parts are recycled and re-pelletized. The two most important factors for producing a quality pellet of recycled plastic with consistent material properties are:

- Re-melting. Proper re-melting of the recycled material occurs under very low shear rates in the extruder and at the lower end of the melt temperature. The objective is to gently re-melt the original material, which ensures maintenance of the material properties.

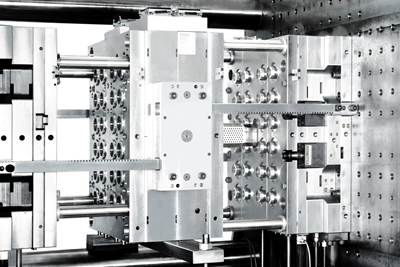

- Melt filtration. The proper filtration process will remove any contaminants in the melt like cellulose, metal or wood pieces. State of the art melt filtration is fully automated and does not require manual operation steps. The melt is filtered continuously at low pressure and can remove particles as small as 70 microns in diameter.

Today’s recycling systems can help produce consistent quality plastic pellets that moldmakers can use in a wide variety of injection-molded parts.

(Source: Putting Recycled Plastics to Work)

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)

_300x250 4.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)