Xact Metal, Uddeholm Partner to Offer Corrax Tool Steel Powder

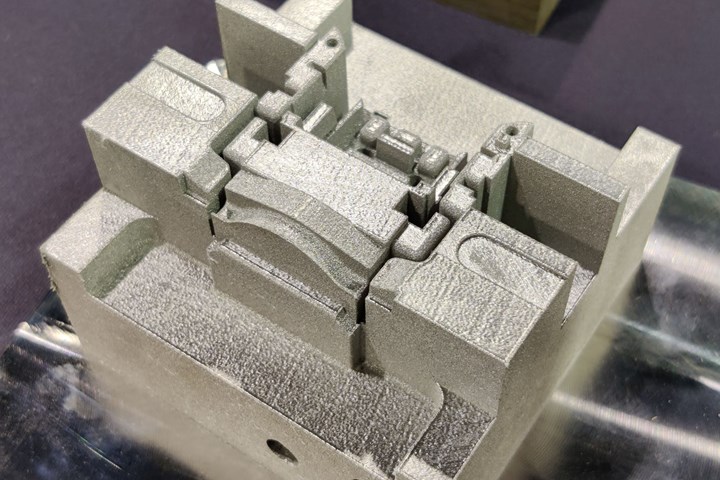

Moldmakers and molders will have access to a mold steel capable of an A1 surface finish post-polishing, supporting the industry’s expansion into metal 3D printing.

With an aim to expand access to affordable metal 3D printing for small-to-medium size companies and decentralize additive manufacturing (AM), Xact Metal announces its partnership with Uddeholm, a voestalpine company, to supply Corrax tool steel for AM, in support of the company’s expansion into the tooling and molding space.

Xact Metal’s goal to break down barriers into powder bed fusion (PBF) technology by providing high-performing metal 3D printers at a low cost, coupled with the introduction of Corrax for AM by Uddeholm, grants Xact Metal customers access to a corrosion-resistant, cobalt-free tool and mold steel capable of an A1 surface finish post-polishing.

“We are proud of our partnership with Uddeholm,” says Juan Mario Gomez, Xact Metal CEO, “which grants us the ability to offer their Corrax metal powder. This intersection between our affordable, high-performing 3D printing technology and Uddeholm’s material expertise is the point where the adoption of AM can begin serving the tooling and molding industry. Uddeholm’s rich history and practical knowledge in the steel industry brings a legacy of excellence and innovation to our collaboration.”

Traditionally, molders and moldmakers have faced limitations in creating optimal internal structures for molds due to the constraints of traditional manufacturing methods. This solution aims to support the adoption of AM in the tooling and molding industries.

According to Kevin Rochford, vice president of sales from Uddeholm, “This partnership brings in a new era of possibilities for the mold and tooling industry, where complexity meets efficiency, and tradition meets innovation. With our long history in the steel industry, this is a natural step forward for Uddeholm.”

In addition to the technological advancements, the environmental benefit of Corrax powder is noteworthy. Uddeholm’s sustainable production practices prioritize using fossil-free electricity to achieve a fossil-free powder manufacturing process.

Xact Metal and Uddeholm will unveil this collaboration at NPE 2024, where attendees will have the opportunity to learn more about Corrax tool steel powder and its impact on the tooling and molding industries.

Related Content

-

VIDEO: How Molds Make Life Happen

Hasco America Inc.'s Engineering Manager, Brenda Clark, brings her lifelong expertise to our MoldMaking Technology audience by shedding light on new innovations, what skills are needed to be successful in the industry and how Molds Make Life Happen.

-

MMT Chats: California Mold Builder Discusses the Difficulties with Silicone Molding and the Power of the Magic 8 Ball

MoldMaking Technology Editorial Director Christina Fuges sits down with M.R. Mold President and Owner, Rick Finnie, to discuss how he began his moldmaking career, M.R. Mold's LSR Education, and the struggles of working with silicone. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

-

A 3D Printing Retrospective

A personal review of the evolution of 3D printing in moldmaking throughout the past 25 years.

.jpg;maxWidth=300;quality=90)

_300x250 3.png;maxWidth=300;quality=90)