At MoldMaking Technology, our team takes great pride in our commitment to delivering an array of invaluable insights and practical advice tailored specifically for our audience within the industry. We bring this insight to our audience via our “Tips” column, a one-page article that is published monthly in MoldMaking Technology magazine as well as on our website that shares expertise and “lessons learned” with fellow mold builders, using real-world examples and supporting data.

Here are our top five most-viewed tips of 2023 based on Google Analytics.

5. How to Address the Mold Engineering Skills Gap

Four ways to equip mold engineers with the necessary knowledge to tackle the skilled workforce crisis.

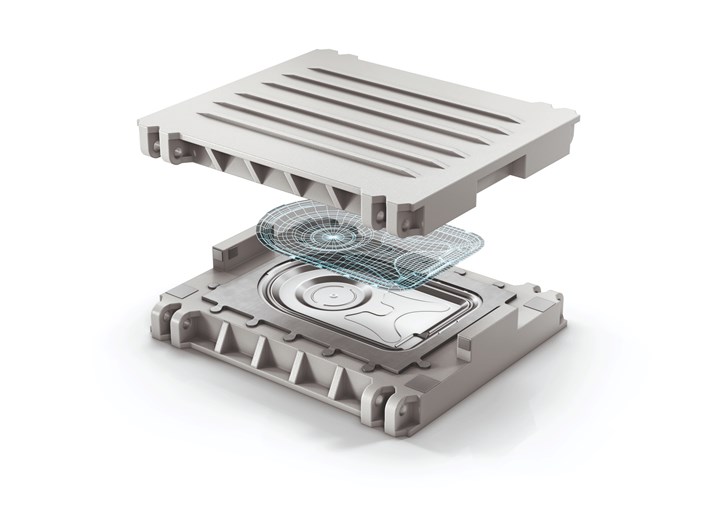

4. CNC or 3D Printing: 5 Factors to Consider

Accuracy, time, cost, nimbleness and application considerations help to determine if a shop should use CNC machining or 3D printing.

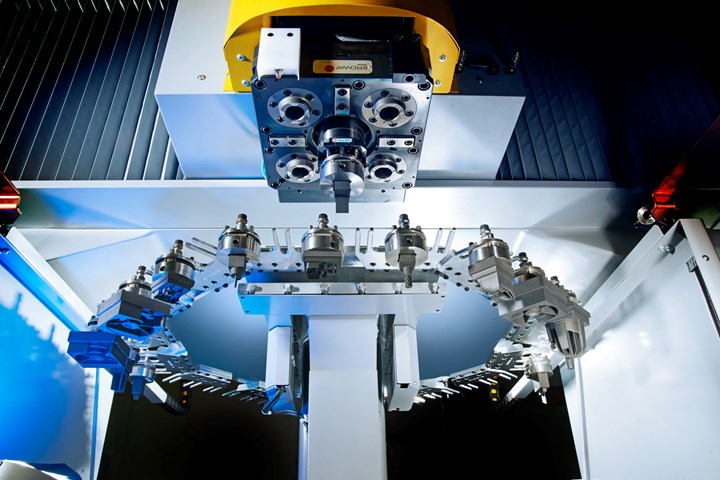

Speed, machine design, software, artificial intelligence and automation help maximize sinker EDM productivity.

2. Three Ways to Accurately Machine Hardened Mold Materials

Three cutting tool design considerations to improve process reliability and cost efficiency when deep-hole drilling molds.

1. How to Polish Ribs for Proper Part Release

Using the right tools and abrasives is essential to polish a mold to the required final finish.

Photo Credit: D.W. Sales

Check out our "Tips" page for more insights from moldmaking professionals

Related Content

-

Predictive Manufacturing Moves Mold Builder into Advanced Medical Component Manufacturing

From a hot rod hobby, medical molds and shop performance to technology extremes, key relationships and a growth strategy, it’s obvious details matter at Eden Tool.

-

2021 30 Under 30 Honors Program: Mentoring in the Next-Generation of Moldmaking Professionals

Young professionals are vital to the moldmaking industry, and it is important to acknowledge those making strides in shaping the industry's future. MoldMaking Technology recognizes the industry's young talent through its 30 Under 30 Honors Program.

-

Exploring ISO 9000 - Part 16 Control of Quality Records

A Series of International Standards for Quality Management and Quality Assurance. We begin 2022 with a review of Clause 4.16 Control of Quality Records.

.png;maxWidth=300;quality=90)