Tips

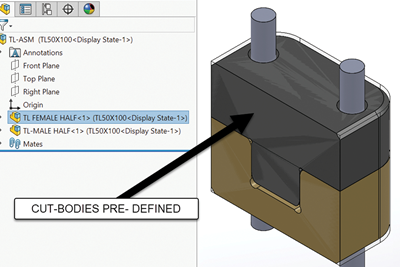

How to Manage a CAD Library

Learn five ways to organize your mold design information.

How is an Aluminum Mold Energy-Efficient?

Nine ways aluminum molds save energy and production costs.

Read More5 Steps to Get Started With Digitalization

Knowledge, a strong partner, an internal champion and an active regular participation in highly visible data will help smaller mold shops with digitalization.

Read MoreFive Benefits of Aluminum Tooling

Aluminum molds are worth a second look as a viable means to swiftly and cost-effectively get products to market.

Read MoreA Simple Guide to Spindle Repair

Understand the causes of spindle failure and the steps for proper repair.

Read MoreHow to Overcome Common Deep-Hole Drilling Challenges

Producing deep holes effectively and efficiently is a challenging application that requires cutting tool solutions that offer predictable cutter life, accurate surface finish and repeatability.

Read MoreHow to Address the Mold Engineering Skills Gap

Four ways to equip mold engineers with the necessary knowledge to tackle the skilled workforce crisis.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

CNC or 3D Printing: 5 Factors to Consider

Accuracy, time, cost, nimbleness and application considerations help to determine if a shop should use CNC machining or 3D printing.

Read More5 Sinker EDM Advancements

Speed, machine design, software, artificial intelligence and automation help maximize sinker EDM productivity.

Read MoreHow to Produce More Accurate Molds and Reduce Rework

Patented micro-milling process for manufacturing steel plate flat and parallel helps mold builders shorten mold build times and increase accuracy.

Read MoreThe ROI of ERP

Seven reasons why a mold builder needs to invest in enterprise resource planning software and technology.

Read MoreHow to Polish Ribs for Proper Part Release

Using the right tools and abrasives is essential to polish a mold to the required final finish.

Read MoreThree Ways to Accurately Machine Hardened Mold Materials

Three cutting tool design considerations to improve process reliability and cost efficiency when deep-hole drilling molds.

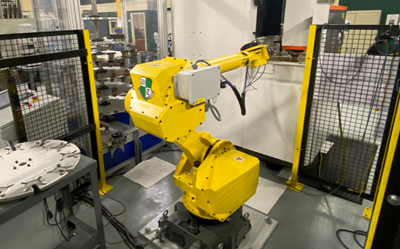

Read MoreHow to Build the Right Automation System

Seven considerations when developing an automation solution for your customers.

How to Eliminate Streaks and Weld Problems with Laser Technology

Laser technology overcomes streaking and welding challenges for new mold textures and texture repair.

Read MoreFive Ways a Hot Runner Is Key to Processing Reinforced Materials

A trusted hot runner supplier should work closely with mold builders and molders to manage the expectations (and realities) of supporting the specification, tool design, installation and service of a hot runner system.

Read MoreFour Uses for Tactile Probing and Laser Scanning in Moldmaking

Laser trackers with their probing and scanning capabilities are embedded in almost every stage of the moldmaking process.

Read MoreTwo Reasons to Form Additive Tooling Partnerships

Partnering with experienced 3D printing resources is essential to remaining competitive in today’s ever-evolving moldmaking industry.

Read MoreTen Things Mold Builders Should NOT Do

What you don’t do can be just as important as what you do, sometimes even more so. One thing great mold builders do is take note of what gets in the way of their success and stop doing it.

Read MoreHow To Get Buy-In from Your Team for ISO 9001

Here are four tips for getting your team on board once you’ve decided to become ISO 9001 certified.

Read More3 Technologies to Help Fill the Skills Gap

Moldmakers can address the labor challenge with robotic systems, simulation products and metal 3D printers.

How to Protect Soft Base Materials

Choose a suitable mold coating to take the abuse and save your base material.

Read MoreWhen to Use Solid Carbide Thread Mills or Indexable Thread Mills

Pointers for choosing solid carbide thread mills versus indexable thread mills.

Read MoreCutter Considerations for Hybrid Additive Manufacturing

Four tips for applying the right cutting tools in hybrid additive manufacturing.

Read MoreHow to Overcome Complex Mold Texturing Problems

Key benefits when considering laser technology for mold texturing and repair.

Read MoreSix CNC Control Features for Moldmakers

A CNC control should have features to automatically smooth the axis movements or allow the operator to set tolerance limits manually.

Read MoreFive Things a Mold Builder Should Know about Non-Contact Blue Light 3D Scanning

Mold builders who use non-contact blue light 3D scanning reap the benefits of digitization throughout the mold manufacturing process.

Read More

.png;maxWidth=300;quality=90)

_300x250 1.png;maxWidth=300;quality=90)