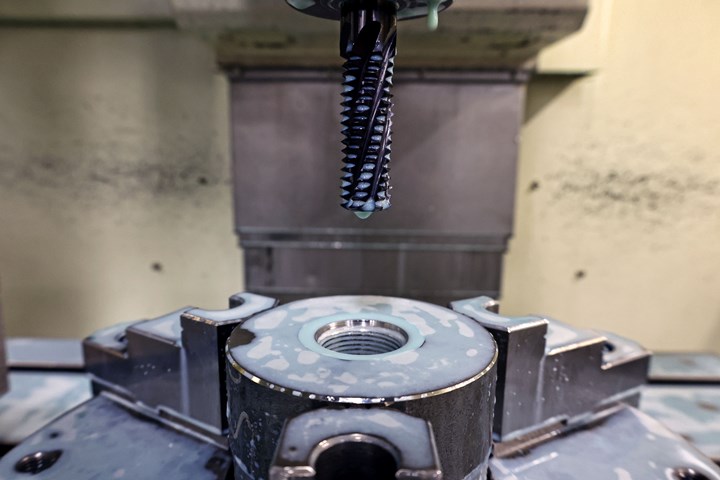

The quality, repeatability and flexibility requirements of an application dictate what type of thread mill to use. Photo Credit, all images: Allied Machine & Engineering

When choosing to thread mill, mold builders must decide between a solid carbide or an indexable thread mill. The choice boils down to the application’s needs in terms of quality, repeatability and flexibility.

Solid Carbide Thread Mills

Quality and performance are critical advantages of solid carbide thread mills. Solid carbide thread mills run and cut faster every time. Having constant surface footage between two different diameters will result in a different rpm. Due to their smaller cutter diameter, solid carbide thread mills will run at a higher rpm. Combined with more flutes, this yields a faster penetration rate (in/min or mm/min) and improved cycle time.

These tools usually outperform indexable thread mills in terms of quality because threads are being ground simultaneously. This improves the consistency of threads. In addition, with a smaller cutter diameter, there is less contact with the workpiece, resulting in less heat generation and deflection.

Indexable Thread Mills

Most users are attracted to indexable thread mills because they can change out thread forms frequently. For example, you can take one body and change out inserts, and the machine is quickly up and running with different forms or pitches. Ultimately, this makes indexable thread mills better for low-production batches and job shop-type work with a lot of changeover and variation in the manufacturing.

This again comes back to the flexibility of the tooling. You have a one-time purchase of the body and then switch over the inserts as needed.

All in all, a thread mill is simply milling a thread form and a pitch and can usually be used for both left- and right-hand threads, internal or external, multiple start threads and various tolerances.

Related Content

-

Forces and Calculations Are Key to Sizing Core Pull Hydraulic Cylinders

To select the correct cylinder, consider both set and pull stroke positions and then calculate forces.

-

Fundamentals of Designing the Optimal Cooling System

The right mold components can help improve mold cooling and thereby produce higher-quality parts.

-

Moldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

.jpg;maxWidth=300;quality=90)