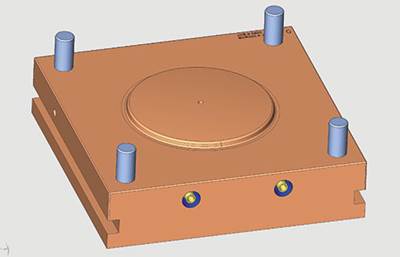

No matter what mold material you choose, always consider part design, resin, part quantity, part geometry, mold builder, molder and industry-standard mold maintenance. Photo Credit: MoldMaking Technology

Aluminum as a mold material can support complex designs, tight tolerances, high aesthetic finishes, unfilled/filled resins and production volumes without compromising quality. The phrase “production quantities” is highly subjective and often used to imply that steel tooling is the only choice. The fact is that most projects’ production quantities can be accomplished easily by aluminum tooling.

Aluminum tooling is a low-cost alternative to steel tooling for lower production quantities up to 1 million shots. Case hardening can produce even higher quantities beyond 1 million. A multicavity tool can bring the production capacity to several million for certain plastic resins.

Today’s aluminum options are better than steel alloys for many mold projects, but you must do your homework. Review the following five reasons to consider aluminum tooling:

-

Design Validation

Education during the design phase when working with an aluminum prototype tool speeds up the final production tool build and part manufacturing. Using aluminum, you can consider complex designs and hard-to-fill resins to validate the final design concept.

-

Mold Cost Savings

Aluminum tooling will always be cheaper than steel tooling. While aluminum is pound-for-pound more expensive than steel, aluminum weighs less and is often less expensive. The major cost savings on an aluminum mold is realized through faster machining efficiencies and longer-lasting cutters because aluminum cuts faster and easier than steel and burns and polishes faster when EDM is necessary.

Aluminum also offers dimensional stability where heat deformation affects critical design tolerances, yielding greater success with complex designs.

-

Part Savings

Aluminum’s greater thermal conductivity makes processing easier and more consistent for each production run, which allows technicians a bigger process window for the best setup to validate the part for production. Faster process cycle times also increase profits and improve available capacity.

Because aluminum molds heat up and cool down faster than steel molds, faster mold setups can be achieved with less scrap for startup and shutdown. Lastly, lower injection pressure can often fill aluminum molds, yielding less machine and mold wear and electrical costs.

-

Part Quality

Aluminum’s natural thermal conductivity also reduces hot and cool spots in a mold, translating into a more stable part. The resin flow through an aluminum mold is normally faster and more consistent, producing a higher-quality part with less scrap.

To validate a new part design before it’s launched into production, consider aluminum because it enables technicians a larger process window even with very intricate and challenging parts. Aluminum also offers dimensional stability where heat deformation affects critical design tolerances, yielding greater success with complex designs.

-

Speed-to-Market

Too often, designs from OEMs take several weeks or months, with first-off part deliveries already behind schedule. Aluminum molds are built faster than steel molds, process more easily and bring a project to market quicker thanks to the material’s improved tensile strength, machinability, low weight, thermal conductivity, uniformed distribution of mechanical properties, electrical conductivity, dimensional stability and high wear resistance.

Related Content

Aluminum Machining Efficiency Improved With Milling Inserts

The TungAluMill line has been enhanced with 10 new XVCT-AM inserts, featuring an interface design that augments machining at high speed rates.

Read MoreCast Plate Aluminum Alloy is Suitable for Production Mold and Dies

Alimex Precision in Aluminum introduces its 7000 series ACP7 mold material, featuring high mechanical properties, material stability and good machinability.

Read MoreHow to Protect Soft Base Materials

Choose a suitable mold coating to take the abuse and save your base material.

Read MoreRoughing, Finishing Aluminum-Specific End Mill Line Expansion

Extended range of Sandvik Coromant’s CoroMill Dura versatile solid end mills engages stable cutting, small burr, good surfaces and minimal vibration.

Read MoreRead Next

Lessons Learned with Aluminum Tooling

Developing a team business plan and making changes to design, operation and maintenance procedures help increase the chances for a successful aluminum mold project.

Read MoreLet’s Be Clear About Aluminum

Within the injection molding industry, a negative perception of aluminum for anything but prototype plastic parts persists, despite aluminum tooling being able to produce and run almost any resin that steel can, as well as produce millions of shots with unfilled resin with uniform results.

Read MoreExpanding Aluminum’s Potential

Hard-coating provides a number of benefits that make aluminum tooling an attractive alternative to steel.

Read More

.png;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)