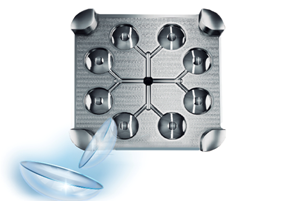

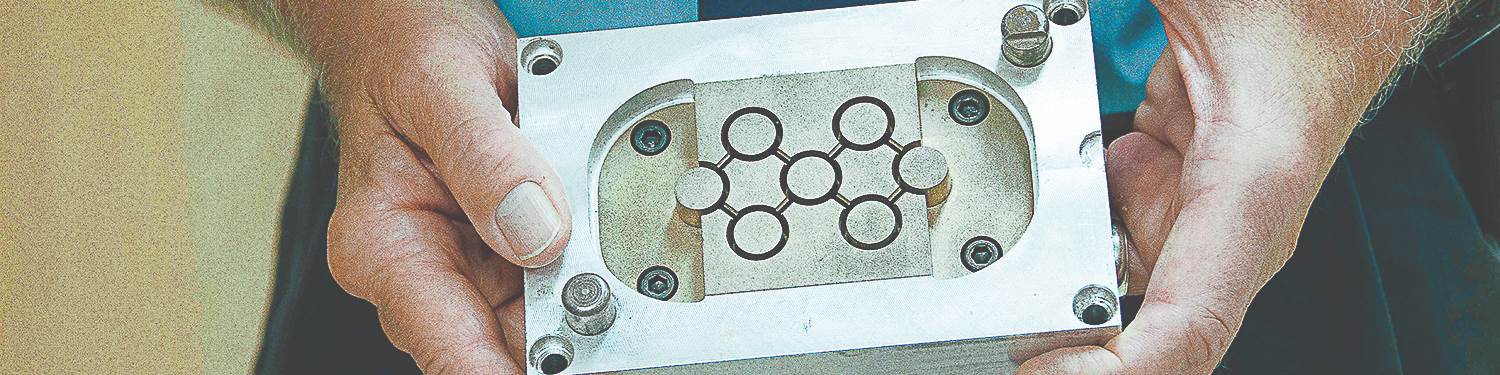

Here, aluminum is used for the mold base because of its superior thermal conductivity, but tool steel is used for the cavity inserts to maximize wear resistance. Photo Credit: Harbec

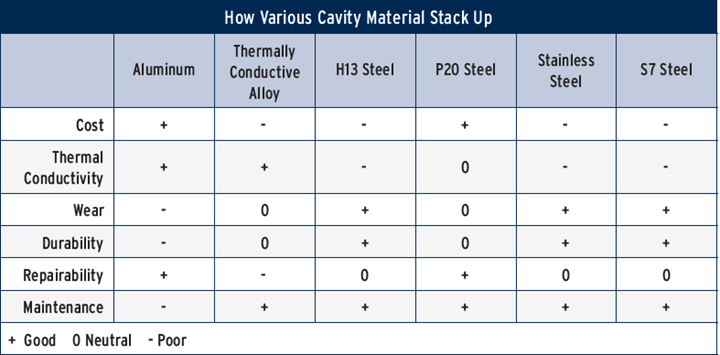

With cavity steel or alloy selection, there are many variables that can dictate the best option for molds. Things that need consideration are the material you’ll be molding, cycle time expectations, part criteria, expected volume, tooling costs and maintenance. The goal here is not to suggest, recommend or give preference to any specific steel or alloy, but to offer some guidance that should be taken into account when making the selection. I’m not an expert on all of the steel types used around the world, so there will be some not mentioned — I’m only writing from my personal experience.

Maintenance is the variable I focus on most in the steel selection process. Most toolmakers that build, maintain and repair production tooling have definite opinions on what they like and don’t like in tool steels. I’ve heard so many varying viewpoints over the years, but I have tried to keep an open mind by taking the big picture into account. So, at times, I’d be willing to accept added maintenance on the tooling if the payback was faster cycles or lower tool costs. But price should never be the main factor. As I often say, it’s cheaper but costs more.

There are pros and cons to each and every option, so it’s important to know all of the angles to understand the long-term cost versus just the upfront tooling costs. If you need a steel that is wear-resistant, you are looking at a hardened tool steel. This will increase your tooling costs upfront but will reduce your maintenance costs in the long term. But here’s the twist: Hardened steels are less thermally conductive, which can impact cooling time if you don’t put extra focus on the tool design to accommodate this drawback. If you go with a standard tool steel that will not be hardened, your cost will be lower upfront but your long-term maintenance cost will be greater.

Price should never be the main factor. As I often say, it’s cheaper but costs more.

You can also apply a coating or surface treatment to reduce wear, which will still be cheaper than hardened steel but will put you at risk if the tool is damaged. Repairing coatings and surface hardening takes lots of time and money, especially for a part with visual requirements. But the thermal conductivity will be 10-15% greater than with a hardened tool steel. Then there are options in aluminum and alloys with much greater thermal conductivity that can have a big payback in cycle time. Again — pros and cons for each option.

What Are You Molding?

The first thing I take into consideration is the material being molded. With abrasive, glass-filled materials, my focus would be on addressing concerns over wear and erosion unless the expected volume is extremely low. But with the most common glass-filled materials, cooling is more critical than with other materials, and the best steels to address wear have lower thermal conductivity. Carbide inserts are the exception; they have excellent wear properties along with great thermal conductivity, but the costs and lead times to replace these need to be considered.

With corrosive materials such as polyvinyl chloride (PVC), stainless steel is a common choice. Using cheaper options will require critical procedures to prevent corrosion. On parts that are expected to have a very high surface finish, tool steels that have lens-grade specs should be considered. For molding materials that do not contain abrasives like glass fibers or corrosive ingredients, P20 steel is the most common choice. But with smaller tools for high-volume production, hardened tool steels are always a good option to prolong tool life with reduced maintenance. On the other hand, aluminum can be an excellent choice for lower-volume tools to reduce cycle times — from a maintenance viewpoint, however, aluminum is not my friend.

Aluminum & Conductive Alloys

Many years back there was a lot of talk and studies about aluminum and its positive impacts on mold build cost and cycle times, both of which can be significant. But there is always a negative that can offset the positive if all aspects are not considered. What’s more, there are many versions of aluminum, and each has very different properties of toughness and thermal conductivity, so never assume that “aluminum is aluminum.” Do your research.

Aluminum is often used for prototype tooling to keep the costs down; the production tooling is then built with a more robust steel. Just keep in mind that the molding results will not be the same, and in some cases can be significantly different, depending on the part geometry and size. The main reason is the cooling factor, as aluminum has much greater thermal conductivity. I would use caution when using aluminum on high-volume parts that have visual specs or on tools that have many lifters and slides. Aluminum is soft and requires extra design attention to make sure it is robust enough, and given extra care in the press to reduce cavity damage.

Alloys such as MoldMax, Moldstar or Ampco can have a big impact on cycle time because of their excellent thermal conductivity. They also come in different hardnesses to accommodate the material being molded. But as you go up the hardness scale with these alloys, their thermal conductivity decreases. These materials are much more robust than aluminum but are also expensive. When used to mold glass-filled materials, these alloys should be coated to prevent erosion, which is an extra cost (along with added maintenance). I will typically use these materials when cavity details are too small or intricate to add waterlines, but I always choose forged rather than cast alloys for cavity details because they have more resilience and will not crack or break as easily. The cast versions are better for wear surfaces or components.

The old-school rule of needing 10 points of HRC spread for components and cavities is not a fact when you move higher on the HRC scale.

The most common, middle-of-the-road tool steel is P20 or similar, which has 28-30 HRC. This steel also comes in a high-hard version (38-40 HRC), and in lens grade when high surface finish requirements are needed. P20 is the first choice in most cases when using plastics without abrasive additives, but as I mentioned earlier, unless it’s for very low-volume use, you will need to protect the steel against erosion with a coating or surface hardening. This has drawbacks, with which I am very familiar.

For very tight-tolerance and high-volume parts, S7 is a common choice. It’s a very durable, impact-resistant tool steel that can be hardened up to 56 HRC. This steel is also much more stable through the heat-treating process, shrinking or expanding less than H13 or stainless steel.

In most cases, cavities are hardened to 50-52 HRC. S7 can also be used for slides or lifters and hardened to 54-56 HRC. At this hardness, S7 has excellent wear properties working against the S7 cavities at 50-52 HRC. I’ve seen tools set up like this running every day all week with intricate lifters and never have an issue with wear or galling.

The old-school rule of needing 10 points of HRC spread for components and cavities is not a fact when you move higher on the HRC scale. On the other hand, running 10 points of spread on the low end is almost a guarantee to create galling issues. I can’t count how many times I have had to deal with galled tools when running P20 cavities at 28-30 HRC and components at 40 HRC. The most common error is ordering pre-hardened H13 lifters at 40 HRC and thinking they are good to go. Wrong. All you need to do is have them nitrided after fit and timed and you’re all set for wear and tear.

Stainless steel is another material option, commonly used not only for PVC but in medical tooling to provide highly polished cavities. The high end for hardness on stainless steel is 50-52 HRC.

H13 is typically the go-to choice for a tool steel to address wear when running abrasive materials. In most cases, cavities are not hardened above 50 HRC — the typical range is 44-48 — to reduce the chances of stress cracks. I have had a tool with H13 inserts running 33% glass-filled nylon for 1 million cycles without any wear issues. But I would not recommend this unless you take very careful consideration in the tool design.

With any tool steel that is going to be hardened, you need to focus on some very important issues. I’m fairly confident anyone reading this who has been in the industry has seen cracked cavities or details that have broken off. Typically there are two things that come to mind as contributors to this problem: Either the HRC is on the high end with bad steel structure in the design; or, more commonly, there is a sharp edge in the tool. That’s why I always try to make sure all pockets for slides and lifters do not have sharp internal corners in the cavity details. Most CAD models will not have a radius on all edges. So when you are cutting or EDM’ing the details, take this into consideration and leave a radius on all internal corners whenever possible.

Updated and republished from Plastics Technology.

Related Content

Three Considerations for Mold Steel Selection

Although a big challenge is selecting the right steel for the right job, steel selection has never been better in regards to quality, price and delivery speed. Here is a simple checklist when selecting your next mold steel.

Read MoreCorrosion-Resistant, High-Hardness Mold Steel for Optimal Surface Finishes

Uddeholm’s premium Tyrax ESR can reduce polishing time by 40-50% and is suitable for long run production molds and high-performance plastics.

Read MoreProject Reveals Added Benefits of New P20 Grade Steel in Machinability, Cycle Time and No Stress Relief

MoldMaking Technology's Christina Fuges talks with General Motors' Shane Appel about a project testing a new P20 steel grade's dimensional stability.

Read MoreModified Composition Enhances Stainless Steel Capabilities

Edro introduces Böhler’s M333 Isoplast stainless steel which has been manufactured via a new melting technology for best-in-class polishability, conductivity, toughness and corrosion resistance.

Read MoreRead Next

Strategic Mold-Material Selection

In determining the right mold material, consider part finish, production volume, part material, cycle time and mold details like molding resin.

Read MoreTake a Second Look at Production Aluminum Tooling

One moldmaker has put aluminum tooling to the test and advises a second look for your high-volume automotive applications because it can address your quality, cycle time and cost challenges.

Read MoreAddressing Aluminum Tooling Objections

Mold builder shares the technical and financial advantages it experiences using aluminum tooling.

Read More_970x90 3.png;maxWidth=970;quality=90)

.jpg;maxWidth=300;quality=90)

_300x250 1.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)