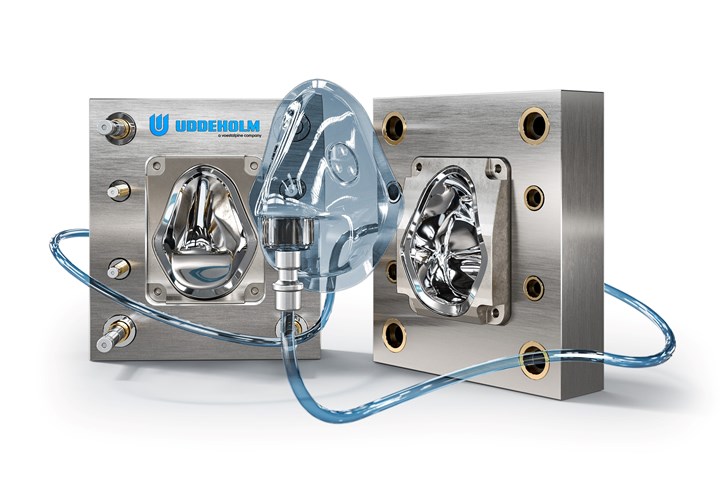

Corrosion-Resistant, High-Hardness Mold Steel for Optimal Surface Finishes

Uddeholm’s premium Tyrax ESR can reduce polishing time by 40-50% and is suitable for long run production molds and high-performance plastics.

Photo Credit: Uddeholm

Uddeholm’s Tyrax ESR is a premium corrosion-resistant and high-hardness (up to 58 HRC) mold steel. It offers excellent polishability, the company says, making it the obvious choice for applications where surface finish is of the highest importance. Moreover, a high-gloss surface finish can be achieved in three polishing steps compared to five steps for AISI 420 ESR, reducing overall polishing time by 40-50%. Uddeholm Tyrax ESR is reported to be a suitable upgrade from AISI 420 ESR, AISI S7 and AISI 440C.

Tyrax ESR is ideal for molding high-performance plastics often filled with glass fiber reinforcements and corrosive, flame-retardant additives. The material is also suitable for long run production molds in the following application areas: lens and lighting molds, medicals molds, injection plastic molding, vinyl extrusion and plasticizing screws.

High ductility and toughness, as well as good dimensional stability when heat treated are additional features that round out this product.

Related Content

-

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

-

Advantages and Disadvantages of Copper and Graphite Electrodes

Both copper and graphite provide approximately the same end result, so it is important for a shop to consider the advantages and disadvantages of each material in order to discover what would work best in their shop floor environment.

-

6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

_970x90 4.png;maxWidth=970;quality=90)

.jpg;maxWidth=300;quality=90)

_300x250 1.png;maxWidth=300;quality=90)

_970x250 4.png;maxWidth=970;quality=90)