6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

Where drilling would draw too much power on low-power machines, this high-feed mill offers the option of instead creating holes by helical ramping. Photo credit, all images: Seco Tools

High-feed milling focuses on removing as much material as possible in the shortest amount of time. It’s a process that’s been around for a while and can open doors to more lucrative business opportunities. Unfortunately, some manufacturers have moved away from the process due to what they consider reliability concerns. And it’s true — if not applied properly, high-feed milling can create some unfavorable results.

For those willing to take the leap, the benefits of high-feed milling can significantly outweigh the potential challenges. The process offers amazing productivity, nearly triple the metal removal rate of conventional methods, and increases tool life. However, there are several things to know in order to make high-feed milling work successfully for you.

Machine Tools

Rigid, highly capable machine tools are a must because the cutters run at high feeds, which require the machine and the control to keep up with these demands. New equipment is a lot more advantageous when dealing with high-feed milling technology. It’s possible to apply new high-feed mills on older machines, but the process works best with large cutters because the feeds and speeds are not as accelerated.

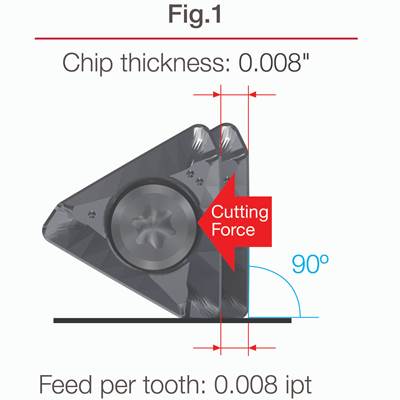

High-feed cutters that use trigon-style inserts, providing the lowest possible lead angle over round or square inserts to direct cutting forces in the axial direction, which is more stable and easier on the machine.

Inserts

Trigon-style inserts provide the lowest possible lead angle over round or square inserts. Low lead angles produce a much thinner chip, which in turn, requires higher feed rates to maintain proper chip thickness for the insert geometry. The lower lead angle also directs the cutting forces in the axial direction, pushing up into the spindle, which is more stable and easier on the machine. Higher lead angles create thicker chips requiring less adjustment in feed rate. They also produce more radial force causing vibration and stress on the spindle bearings.

Insert Grade

Make sure you have the right insert grade for your job because you don’t want your tool to fail prematurely, especially if you’re performing a lights-out operation. Choosing the correct insert grade for the type of material you are machining can increase tool predictability, resulting in fewer tool changes, less rejects and less reworking.

High-feed mills are well suited for plunge milling because they are free cutting and provide efficient chip evacuation.

Machining Application

Not every machining method is created equal. While high-feed mills with long overhangs are great, for high-speed options for milling processes, you need to remember you can’t run them as fast as you would tools with shorter overhangs without adding specialized vibration dampening toolholders or reducing cutting speed. When a tool with long overhang operates faster than it should, you can experience increased vibrations, causing insert chipping and premature insert failure.

Programming

Optimize the cutter path through proper programming, so you don’t put any unrealistic demands on the cutting tool. For example, when you are in a mold and come to a corner, changing directions without using a smooth transition is very hard on a tool because it creates a large angle of engagement. A good rule of thumb is to program an arc that is 50% larger than the cutter diameter. If using a 2.0" cutter, program a 3" diameter arc. Programming an arc in pocket corners reduces the angle of engagement and avoids overloading the cutter. Machine tools can also have problems in this area because several calculations are involved in generating an arc. If the machine tool can’t properly calculate the arc, the tool path can become erratic.

Engaged Tools

Keep your high-feed mills as engaged as possible across the full diameter or less than half the insert width. One of the reasons these mills work so well is because their cutting forces are directed at the machine spindle in the axial direction to create balance. If you use the same cutter and only engage it 50 or 60% of the diameter, you will experience push and increased vibrations because the cut is unbalanced.

Related Content

Advantages and Disadvantages of Copper and Graphite Electrodes

Both copper and graphite provide approximately the same end result, so it is important for a shop to consider the advantages and disadvantages of each material in order to discover what would work best in their shop floor environment.

Read MoreMoldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

Read MoreMachining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

Read MoreThe Benefits of Hand Scraping

Accuracy and flatness are two benefits of hand scraping that help improve machine loop stiffness, workpiece surface finish and component geometry.

Read MoreRead Next

Considerations for a High-Feed Milling Strategy

High-feed milling is becoming the chosen methodology for removing as much material as possible in the shortest amount of time, as more shops equip themselves with high-speed CNC machining capability and sophisticated CAM programs.

Read MoreHow to Achieve Accelerated Milling

High-feed milling reduces cycle time and extends cutting tool life.

Read MoreFinding the Right High-Feed Indexable Milling Tool

The value of versatility and reliability in your high-feed machining solution.

Read More

.jpg;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)