Conformal Cooling

Digital Edition of September's AM Supplement Now Available

This month's issue includes two features. One on repairing damaged mold inserts using direct metal laser sintering and the other on a tool and die and CNC machining job shop with an unusual employee development philosophy that employs additive manufacturing.

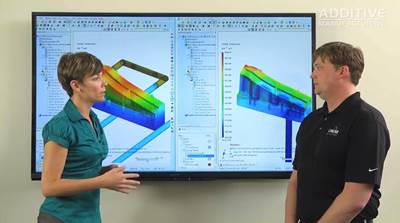

Read MoreMMT Visits Linear Mold to See Additive Mfg in Action

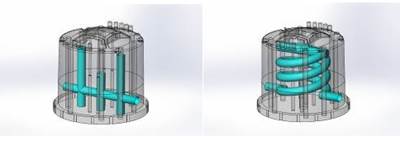

Linear Mold & Engineering opened its doors to us to talk about how they’re using additive manufacturingI to grow conformal cooling channels inside mold inserts and to make production parts for the aerospace and medical industries.

Read MoreComplementing Laser Sintering with EDM

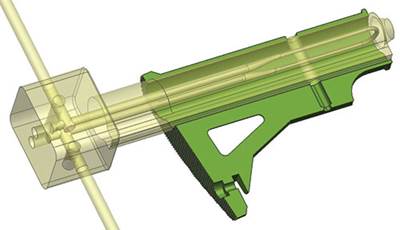

Laser sintering unlocks the potential to “grow” conformal-cooled inserts from the ground up. Wire EDM ensures production proceeds at a pace that keeps up with demand.

Read MoreThe Intersection of Laser Sintering and EDM

For this moldmaker, wire EDM helps streamline production of inserts that are “grown” with cooling lines already inside.

Read MoreMetal Laser Sintering Hybrid Milling

Metal laser sintering hybrid milling combines metal powder 3D laser sintering with high speed milling finishing into one machining system.

WatchLaser Sintering and Milling Working Together

A hybrid manufacturing process offers mold builders an alternative method for making cores and cavities with time and cost savings and increased consistency.

Read MoreThe Marriage of Moldmaking and DMLS

Three factors influenced this molder's decision to use direct metal laser sintering: a decrease in waste, faster mold production and design flexibility.

Read MoreCarving out Savings at the Front End

Positive-geometry cutting tools help this shop double-down on a key time-saving strategy by reducing machining time on aluminum MUD frame inserts.

WatchLaser Focused on Moldmakers

A new partnership brings to North America a metal laser sintering hybrid milling machine that can fabricate molds and dies with very complex geometries in one piece with high accuracy, shortening lead time and reducing manufacturing costs.

Read MoreMaking the Right Mold Material Selection for Thermal Management of Molds and Inserts

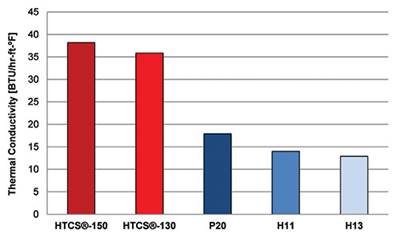

The engineering of a mold greatly determines the performance of the plastic injection molding process, because it directly influences cycle time and process productivity. Here we review why productive thermal management of a mold is essential in determining the cost-effectiveness of the molding process.

Read More.png;maxWidth=970;quality=90)

.jpg;maxWidth=400;quality=70)