MoldMaking Technology Noteworthy News, May. 24, 2021

Reverse Engineering Software Removes Workflow Complexity; External Latch Lock Reliably Controls Mold Plate Sequencing; Tabletop Industrial Robot Enhances Versatile Processing and Handling, and more.

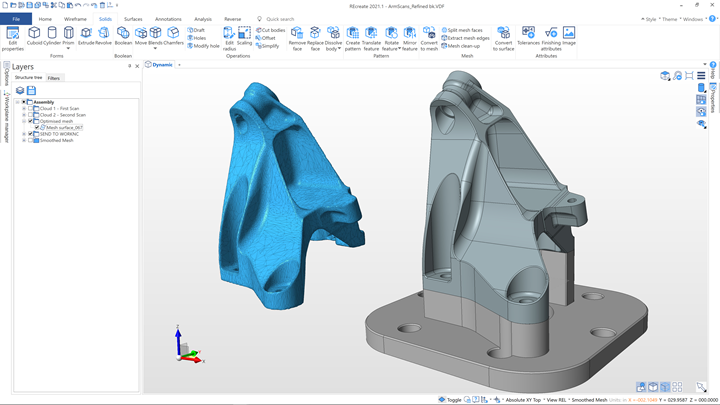

Reverse Engineering Software Removes Workflow Complexity

Hexagon simplified reverse engineering processes provides a single working environment from scan to manufacturable CAD model.

Photo Credit: Hexagon

Hexagon’s Manufacturing Intelligence division has unveiled REcreate, a powerful and flexible new software solution designed to make it easier and faster to reverse engineer parts from metrology scan to manufacturable model via more streamlined digital workflows.

Designed to remove complexity, REcreate is said to provide a single working environment from scan to manufacturable CAD model. Users can prepare CAD models and drawings from any point cloud data. The software’s fully featured CAD tool suite enables users to create complete and manufacturable CAD models as well as 2D engineering drawings. REcreate’s analysis tools also allows manufacturing professionals to interrogate those 3D models and validate whether they are manufacturable before exporting as CAD or STL for computer aided manufacturing (CAM) or additive manufacturing (AM) processes.

While designed to be interoperable and slot into a customer’s existing processes, Hexagon says the solution offers additional benefits to customers that use other Hexagon technologies in their workflow. Sites that use Hexagon’s portable arms for inspection can reduce training needs by allowing any operator to read inspection data directly from the device to reverse engineer. REcreate is also rigorously tested with Hexagon’s production software tools that are used to plan, optimize and program machining processes.

External Latch Lock Reliably Controls Mold Plate Sequencing

The DME EZ-LATCH patent-pending lock design provides a long-lasting, more reliable easy-to-install lock for plate sequencing.

Photo Credit: DME Company

DME has released a new external latch lock, the EZ-LATCH, which reportedly provides customers long-lasting, more reliable functionality for plate sequencing.

External latch locks are commonly used in a range of different mold designs requiring plate control, including molds with three-plate sequencing, two-stage ejection, early return systems and a moving (core) and stationary side (cavity) ejection application. DME notes that, while springs or friction devices are normally in place to trigger the locking mechanism, they are prone to failure over time, and often require custom manufacturing to meet the specific application needs.

Alternately, the patent-pending DME EZ-LATCH strengthens the external latch lock system for a safer, more reliable method of controlling plates. Further, with its novel design and easy installation, DME says that, depending on the application, the system can be an alternative to more expensive hydraulic cylinders used for sequencing plates.

Unlike traditional external locks which need to be vertically mounted, DME reports that the EZ-LATCH Lock can be installed horizontally, enabling its use on plates as thin as 7/8”. Further, the DME EZ-LATCH lock needs no machining modifications and requires only the selection of the appropriate body and latch bar lengths.

The system comes in multiple lengths to sequence the plates and deliver perfect timing. EZ-LATCH is available in many latch bar lengths covering the widest range of stroke requirements. A long latch bar version providing longer delayed ejection is also available. DME notes that standard sizes accommodate most, if not all mold base sizes and applications; however, DME also provides special sizes available upon request by contacting: dme_mech_eng@dme.net.

Tabletop Industrial Robot Enhances Versatile Processing and Handling

Ten new model variations of the FANUC America LR Mate 200iD/14L robot series offers a 14-kilogram payload and more flexible accommodations for limited workspaces.

Photo Credit: FANUC America

FANUC America introduced the LR Mate 200iD/14L, the tenth model variation of the LR Mate series of tabletop industrial robots. The series’ reliability, lightweight tabletop size and ability to process or handle parts weighing up to 14 kg make it popular amongst manufacturers, the company says. LR Mate robots are applicable for the automotive, e-commerce and warehousing, food and beverage, medical device and pharmaceutical industries, and is offered in ten models, which include cleanroom and wash-proof versions, each with various wrist speeds and reaches to accommodate all workspace limitations.

FANUC America says the LR Mate 200iD robots offer a “best-in-class” work envelope for both upright and invert mount installations. The LR Mate 200iD robot series also offers an ISO Class 4 cleanroom/food-grade variant for food handling and healthcare packaging applications.

These small tabletop robots can be equipped with a variety of intelligent features including robot vision and force sensing functionality for higher levels of accuracy and productivity.

A slim arm—available in three variations, standard, short and long—and a compact footprint minimizes interference to peripheral devices in tight spaces. Wrist load capacity can hold from 4-14 kg, with up to a six-axis articulation. The company notes the series’ fast joint axes speeds, which are said to maximize system throughput, as well as flexible mounting, ranging from upright, to invert or angle. Overall, all LR Mate 200iD robots can be easily integrated into machines and are said to feature the lightest mechanical unit in its class.

Integrated 24VDC power, signal and air enable easy end-of-arm-tool connection, and an integration thru-arm cable option provides iRVision, force sensing, Ethernet and auxiliary axes. Additionally, standard IP67 rating allows operation in factory environments with dust and oil mist; many variants have an optional IP69K rating for wash-proof, cleanroom or food- grade environments.

Post Processor Optimizes CNC Five-Axis Capabilities

Mastercam’s new post processor unlocks faster and more accurate “art to part” FANUC CNC capabilities.

Photo Credit: FANUC America

Automation solutions provider FANUC America and CNC Software, CAM systems provider of Mastercam, introduce a new post processor designed to optimize FANUC CNC five-axis capabilities. The new post processor reportedly enables advanced machine tool operators to reduce their cycle times while boosting part accuracy, particularly for CAD/CAM-generated five-axis simultaneous contouring part processes. Further, machine tools will be able to produce parts—modeled in the CAD system—more precisely.

According to Rick Schultz, aerospace program manager for FANUC America, for five-axis simultaneous contouring, a quality CAD/CAM system is critical. Thus, both companies developed a post processor that makes it easier for programmers to create optimal tool paths using the advanced algorithms available in the five-axis Milling Standard Package for FANUC’s 30i-B and 30i-B Plus Series controls.

Key functions in the Milling Standard Package for FANUC controls include Tool Center Point (TCP), Workpiece Setting, Error Compensation (WSEC), Easy Setting Function to support multiple acceleration and process profiles and advanced look-ahead algorithms AICC II with Smooth Tolerance Control+.

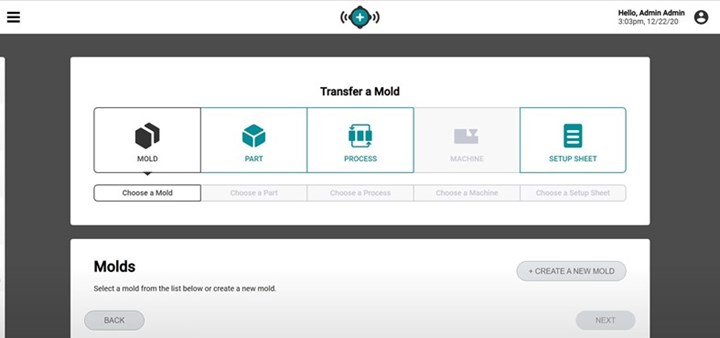

Injection Mold Networking Software Application Reduces Mold Transfer Inefficiency

The Hub for Mold Transfer offered by RJG facilitates standardized processes, improves organizational efficiency and ensures proper mold and machine matching across global facilities.

Photo Credit: RJG

RJG’s injection mold networking software, The Hub, now has a new application available: The Hub for Mold Transfer.

The Hub connects RJG’s CoPilot process monitoring systems to a single interface, enabling users to access all plant information globally, make data-driven decisions, increase visibility, decrease liability and improve operational efficiency. Alternately, RJG says the Hub for Process Analytics enables users to access real-time data from anywhere, review and export reports, view job audit reports, replay historical data and more.

Moreover, the Hub for Mold Transfer is said to permit an easy transfer of molds by automatically generating machine-specific setup sheets, recommending compatible machines and providing a database to store and share part, mold and machine documentation across the organization. According to the company, this application significantly reduces the risk of damage and poor quality by ensuring proper mold and machine matching.

The Hub for Mold Transfer also features:

- Facility asset database for machines, molds, parts and materials

- Mold match recommendations for fit and capability

- Universal process sheet database

- Machine-specific setup sheet database

- Automatically generated, machine-specific setup sheets

- Revision history.

Related Content

Solving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

Read MoreMoldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

Read MorePlastic Prototypes Using Silicone Rubber Molds

How-to, step-by-step instructions that take you from making the master pattern to making the mold and casting the plastic parts.

Read MoreIt Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

Read MoreRead Next

Are You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More

.jpg;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)