420 Stainless Steel Qualified With TrueShape 3D Printing Technology

NPE2024: Mantle highlights its additive manufacturing technology designed for precision tooling, including the availability of 420 Stainless Steel.

Mantle has announced the availability of 420 Stainless Steel for use with its TrueShape 3D printing technology for precision tooling. No hardware modifications or additional components will be required for use with the company’s P-200 printer. The 420 Stainless Steel will be available in the second half of 2024 and will require only an over-the-air software update.

The TrueShape 3D technology, which incorporates fused deposition modeling and CNC machining, enables rapid toolmaking with reduced or even, in some cases, no postprocessing. The process begins with a metal paste which is added in layers. Periodic drying and CNC steps build up the shape of the tool, which is ultimately transferred to an oven for sintering.

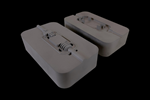

An injection mold insert printed in Mantle’s 420 Stainless Steel. Source | Mantle

According to Mantle, the pursuit of the new material was driven by customer requests. TrueShape 3D was launched with P20 steel, with the later addition of harder H13 steel. The new material will offer similar hardness to the H13, adding superior corrosion resistance.

The availability of stainless is expected to be beneficial to customers in corrosive environments, such as manufacturing locations in tropical climates. Corrosion is particularly of concern with conformal cooling channels, enabled by additive manufacturing technologies, which offer more efficient cooling than linear channels, thus enabling faster cycle times.

At NPE 2024, Mantle plans to display examples of printed steel tooling from the Trueshape 3D technology, along with the metal paste the process begins with, setting up a stark comparison: from a mixture of metal particles, adhesive and solvent that is described as having the consistency of toothpaste, to a dense, heavy, stainless-steel tool ready for industrial injection molding.

Related Content

-

6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

-

Laser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

-

Fundamentals of Designing the Optimal Cooling System

The right mold components can help improve mold cooling and thereby produce higher-quality parts.