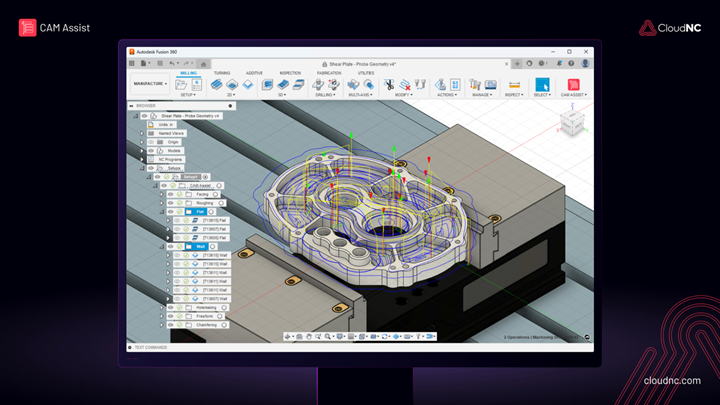

AI-Aided Software Accelerates CAM Programming Time by 80%

CAM Assist from CloudNC automatically generates professional machining strategies in seconds, enabling U.S. manufacturers to be more productive, reducing lead times and eliminating the skills gap.

CloudNC, a manufacturing technology company backed by Autodesk and Lockheed Martin, is presenting its CAM Assist solution as a plug-in for Autodesk’s Fusion 360 software platform, enabling U.S. manufacturers to precision machine components more quickly and efficiently.

CAM Assist uses AI to generate professional machining strategies for three-axis parts in seconds, versus the hours or even days it may take CNC machine programmers to manually select the correct tools, strategies and techniques when machining a new component, often determining between hundreds of thousands of potential variables and approaches. Consequently, programming a CNC machine — a common bottleneck — is reduced by up to 80%, according to side-by-side trials conducted with CAM Assist and senior CAM programmers

According to CloudNC, that gain enables manufacturers using CAM Assist to raise productivity and shorten lead times. In addition, the software frees up time for experienced programmers, while also enabling junior employees to program more complex parts and be productive faster, helping fill the widening skills gap.

CAM Assist uses advanced computational optimization and AI inference techniques to rapidly determine a professional strategy and toolset needed to manufacture a part, along with the most appropriate cutting speeds and feeds from the user’s library. Used alongside Fusion 360, users can upload a 3D model of a three-axis component and the software determines the best milling tools needed from those available, and how they will be used. From there, CAM Assist drafts the code required to instruct a CNC machine how to make it, within the user’s existing CAM platform.

While the software today performs best with three-axis components, multi-axis and freeform capability will be accessible to beta customers shortly.

CAM Assist is publicly available to download today for CAD and CAM programmers using Autodesk Fusion 3D, via the Autodesk App Store or at www.cloudnc.com.

Related Content

-

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

-

6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

-

Laser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

.png;maxWidth=300;quality=90)