IMTS Exhibitor Shares Sustainability and Hybrid Manufacturing Presentations, CAD/CAM/CAE Software Demos

At IMTS 2022, Autodesk is sharing manufacturing industry insights, presentations on sustainability and hybrid manufacturing and showcasing how technology extensions enhance Autodesk Fusion 360’s capabilities.

At IMTS 2022, Autodesk Inc. shares manufacturing industry insights, presentations on sustainability and hybrid manufacturing, in addition to showcasing how technology extensions enhance Autodesk Fusion 360’s capabilities. Presentations include:

- Main Stage outside South Hall | Tuesday, September 13, 10:30 a.m.: Autodesk VP of product development and manufacturing solutions, Stephen Hooper, will keynote on manufacturing opportunities created by working remotely, disrupted supply chains and sudden shifts in consumer demand. Hooper will cover evolving tools and technologies that help manufacturers build resilience, improve collaboration and thrive through change using automation.

- In the IMTS conference | Wednesday, September 14, 11:00 a.m. CET: “Realizing Carbon Balanced Production through Quality Control” will be presented by Richard Stubley, Autodesk technology consulting manager.

- McCormick Place, West Building | Thursday, September 15, 2:15 p.m. CET: “Accessible Hybrid Manufacturing: Autodesk Fusion 360 and Phillips Corp.,” will be presented by Brian Kristaponis, Phillips Corp.’s general manager of Hybrid Manufacturing.

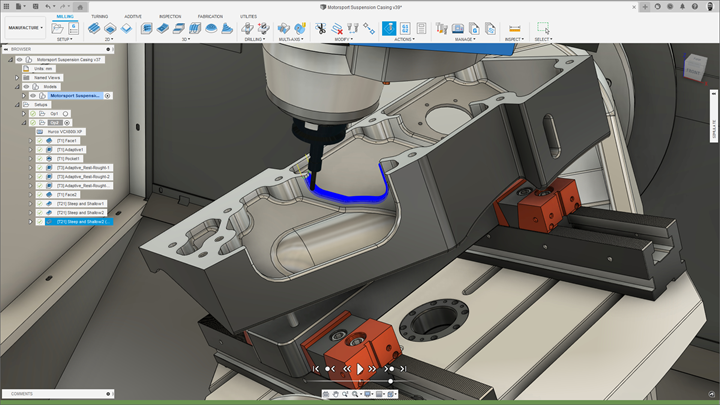

At Autodesk’s booth #133310, the company is also demoing Fusion 360 software. According to Autodesk, Fusion 360 helps mold builders plan, design and optimize their tools using a single, unified, cloud-based CAD, CAM and CAE platform. The ability to use a single platform throughout their design reportedly streamlines workflows and enables quick project collaboration and project management. The addition of Fusion 360 Extensions also introduces more advanced operations, such as programming automation, simplified toolpath modification, part inspection and even injection mold cavity filling simulation, each accessible without exiting Fusion 360 software.

Recent updates include a Machining Extension, advanced four- and five-axis simultaneous toolpaths and more accurate part inspection. Autodesk’s Certification Program offers eight role-aligned, industry-validated certifications in Fusion 360 CAD and CAM workflows.

Related Content

-

How to Solve Hot Runner Challenges When Molding with Bioresins

A review of the considerations and adaptations required to design hot runners and implement highly productive injection molding operations.

-

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

-

Perspectives on Sustainability in Mold Building: A Diverse Outlook

In conversations with individuals involved in the mold building industry, a variety of perspectives on sustainability emerged, showcasing the multifaceted nature of the term.