MMT Blog

MMT Chats: Talent Crisis Meets 2030

The manufacturing industry faces a critical talent shortage as baby boomers retire while reshoring creates new demand and technology transforms workflows.

WatchStrategic Mold Venting

Venting is one of the most crucial, but often overlooked, aspects of mold design and manufacturing.

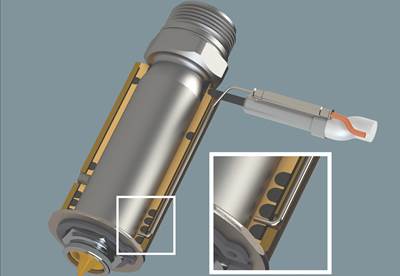

Read MoreHow to Troubleshoot "Actual" Hot Runner Controller Temperature

A first-person account of how one technology supplier did not give up until it solved the mystery of a recent part defect.

Read MorePlastic Injection Molding Starts with the Pellet

This summer, let’s get back to the basics. For this summer school basics series, Pellet to Part explores each stage of the plastic injection molding process. This week: what every moldmaker should know about raw materials, including the fundamentals of viscosity curves, Melt Flow Index, Melt Flow Rate, shear and more.

Read MoreShop Talk: Plastics and Pliers Panic

Canon Virginia, Inc. celebrates the real-world moments that unite shop floors everywhere. We hope that by sharing industry stories together, we can all laugh, learn and grow.

Read MoreShop Talk: Mishaps, Memories and Moldmaking

Where moldmaking stories become industrial folklore.

WatchMMT Chats: Mold Design Apprentices Speak Out

Mold Design Apprentices Alex McClinton and Nolan Benedict share their individual journeys to moldmaking, impressions of a unique mold design apprenticeship and their future plans.

WatchStudent Executives Manage Business, Academia in High School Vocational Program

Bend Manufacturing, a business led by high school seniors that operates out of The Portage School of Leaders in South Bend, Indiana, is witnessing its real-time return on investment: its students.

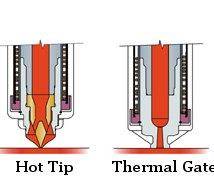

Read MoreWhy Choose a Valve-Gated Hot Runner?

Moldmakers need to be aware of how different gating technology can affect their customers when designing a hot runner system into a mold.

Read MoreStreamlining Medical Device Development With Modular, Risk-Reducing Tooling Strategy

Fast-Track Tooling enables early validation of medical device designs, reduces risks, accelerates time-to-market and ensures alignment with production molds.

Read MorePowerful Portal Milling Machine Has Big Impact on Michigan Compression Moldmaker

Significant 30% increase in production due to a spacious workspace, advanced cutting capabilities and a new generation CNC control system.

Read MoreResilient by Design: Moldmakers Respond to Tariff Tensions With Strength and Strategy

Amid tariff uncertainties, moldmakers must stay flexible, control what they can, plan for multiple scenarios and maintain team alignment.

Read More