MMT Blog

MMT Chats: Virtual Reality Transforms Plastics Training

Innovative technology bridges skills gap through immersive learning experiences.

WatchAutomation, Welding, Software and Venting

MMT’s Editorial Advisory Board member Corey Fox, Operations manager for Accede Mold & Tool, shares his top MoldMaking Technology articles over the past year and how this content has been valuable to the business.

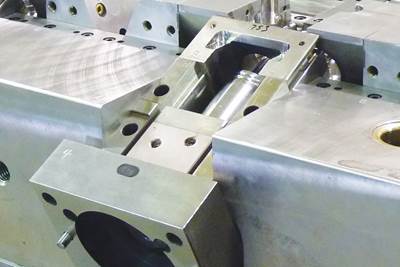

Read MoreHow to Solve Core Pull Flash and Part Issues

Many mold problems can be solved by simply providing enough preload force on the core to prevent movement.

Read MoreIn Case You Missed It: Top May Content

If you didn’t have time to keep up, no worries. We’ve rounded up the top articles from May so you can catch up on what your peers were reading, sharing, and talking about.

WatchISO 9001 Standard Revision Nears 2026

ISO 9001:2015 update targets September 2026, addressing digitalization, AI and sustainability; transition period likely to follow for certified organizations.

Read MoreHow to Assess and Control Surface Texture Quality

Surface texture measurement offers better methods for describing plastic surfaces.

Read MoreMMT Chats: The Family of Business – From the Farm and into the Future

MoldMaking Technology Editorial Director Christina Fuges interviews the Eberle brothers of 2024 Leadtime Leader Award Winner Dynamic Tool Corp. about their moldmaking journey and the family dynamic of the business.

WatchWhat You Should Know About Injection Mold Safety Straps

Every mold should have one in order to be safe and OSHA compliant.

Read MoreMachining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

Read MoreSensors, Sustainability and Skilled Labor

Q&A with Bob VanCoillie, MoldMaking Technology EAB member and senior manager of Kenvue’s mold management center of excellence.

Read MoreProblem-Solving Powers MPP's Growth

Long-time Michigan mold builder expands its capabilities, incorporating molding and embracing automation, while maintaining its collaborative problem-solving approach and apprenticeship program.

Read MoreReal-Time Mold Monitoring Boosts Molding Efficiency and Cost Savings

FloControl software integrates with existing mold design tools, offering real-time tracking and optimization from design to production, enhancing efficiency and reducing costs for ProPlastics.

Read More