MMT Blog

Defining and Understanding Project Scope

Establishing new product development project scope requires clear goals, resource allocation, champions for technologies and flexibility for trial and error.

Read MoreMMT Chats: Molds, Molding, Marketing and Membership

MoldMaking Technology Editorial Director Christina Fuges chats with Eric Hecker, Sales and Project Engineer for Eifel about his focus on sales and marketing, the move into molding, technology and training trends and his mission to help increase membership in Mold Technologies Division of SPE.

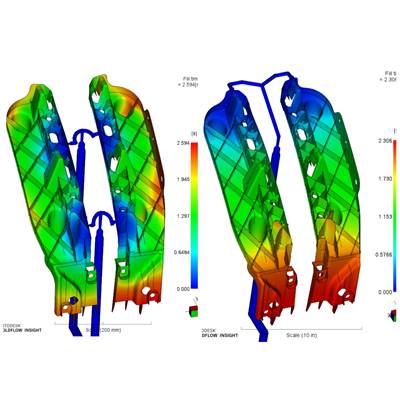

WatchWarpage Waylaid Via Simulation

Designed to form a component that would hold headlights in place, the mold was intended to produce a front-end automobile bracket. Instead of parts however, the tool’s real output was problems.

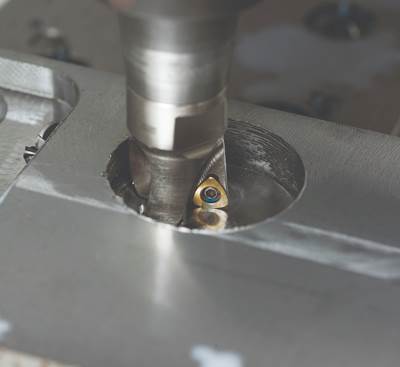

Read More6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

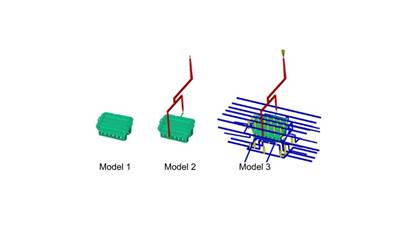

Read MoreHow to Achieve Simulation Success, Part 1: Model Accuracy and Mesh Decisions

Molding simulation software is a powerful tool, but what you get out of it depends very much on your initial inputs. Follow these tips to create the most successful simulation possible.

Read MoreHow 3D Printing Supports Toolmaking Workforce at This Multiscale Molder

At more than a century old, General Pattern has seen multiple evolutions in its business — the latest of which is the embrace of additive manufacturing technologies for mold tooling and beyond.

Read MoreMMT Chats: Helping Small Manufacturers Embrace AI

IT Expert Mina Girges shares simple ways to implement AI by starting small, fostering innovation, integrating securely and scaling strategically to enhance efficiency.

WatchMoldmaking Index Continues Strong 2025 with 52.4 in March

Six consecutive months of improving results push moldmaking market further into expansion.

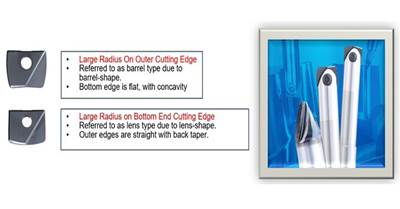

Read MoreWhy Mold Builders Should Consider Barrel Cutters and Lens Tools If They Haven’t Before

Reduce machining cycle times and improve surface finishes of cavity and core work with barrel cutters and lens tools.

Read MoreHow to Expand the Use of Aluminum Injection Molds

Six factors to consider to broaden the application of aluminum molds.

Read MoreDeep-Cavity Cooling Made Easy

G.A. Roeders uses an advanced cooling system employing gun drilling to deliver high-pressure water to quickly and evenly cool areas deep within a mold cavity.

Read More5 Trends in 3D Printed Injection Mold Tooling

3D printing has moved beyond conformal cooling, and is now being applied to injection molds more broadly. Observations on additively manufactured mold tooling from the Plastics Technology Expo — PTXPO 2025.

Watch