All photo credit: OSG USA Inc.

When mold shops made the jump from traditional machining to high-speed machining, they greatly reduced finishing cycle times. The high-speed machining centers offered more rigidity, higher rpm spindles (10K to 15K), better accuracy and faster controls. These same improvements have been made to cutting tools, which can also reduce cycle times and lengthen cutter life.

Mold builders aiming to reduce machining cycle times and improve surface finishes for mold work should consider barrel cutters and lens tools. Here we’ll explain their features and functions, niche applications and benefits—backed up with test cut data to illustrate the value of these cutting tools to mold builders.

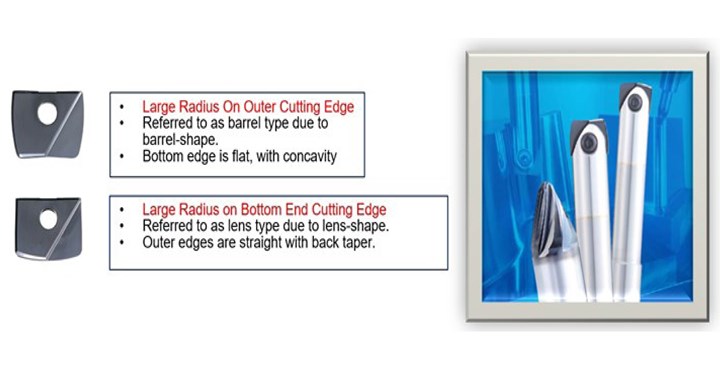

Figures 1 and 2.

If workpieces have larger free-flowing surfaces for which a shop typically uses a ball end mill or an end mill with a corner radius for finishing, it may be time to check out barrel cutters and lens tools. These cutting tools were developed for machining aerospace parts with large free-flowing surfaces (see Figures 1 and 2) and not very small, intricate parts. Medium to large cavities and cores, plastic injection and compression molds, forge dies, die-cast dies and some stamping dies are ideal applications for these cutting tools.

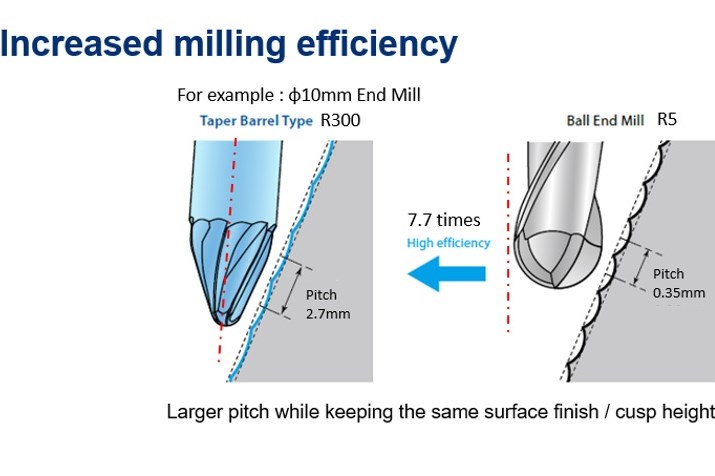

Figure 3.

When using barrel cutters and lens tools for finishing operations, step-overs and step-downs are very large compared to ball end mills or bull nose cutters. Most machining time is spent using ball end mills or bull nose tools to finish surfaces that require small depths of cut and step-overs (0.003 to 0.01 inch). However, barrel and lens tools can offer 0.08 inch for depth of cut and step-over. Also, surface finishes are much better due to fewer cusps compared to ball end mills and bull nose tools (see Figure 3).

Doing the math will reveal a dramatic reduction in finishing cycle times by half and more.

Related Content

-

Ejector Pin Selection Guide

A review of materials, treatments and coatings to help determine the proper pins for optimized plastic part ejection.

-

Maintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

-

Why Choose a Valve-Gated Hot Runner?

Moldmakers need to be aware of how different gating technology can affect their customers when designing a hot runner system into a mold.

(4).png;maxWidth=300;quality=90)