As the editorial director of MoldMaking Technology, my primary focus is to stay on top of important industry trends and technologies (like you), and present that information across MMT’s many platforms—a printed article, a social media post, a webinar or a video.

Let’s talk about the latter—videos. I’ve heard that effective educational videos can allow content to stay with you longer and stir up questions. All of this can lead to greater understanding, improved skills, increased collaboration and better problem-solving.

So instead of writing a feature for a few recent hot topics, I caught a few experts on camera to speak directly to you. Here is a glimpse at the questions to which I sought answers. We will be releasing these quick virtual lessons in the months to come on moldmakingtechnology.com.

1. What makes a CNC suitable for moldmaking?

- What do you need to look for in a control to maximize machining capability and deliver precise, well-finished molds?

- Can you share a specific moldmaking application to demonstrate the use of the proper control to solve vibration issues?

2. Why are human resources and marketing key to solving the workforce challenge?

- Can you explain the 2030 concept?

- How has COVID-19 impacted 2030 in North America?

- How do HR and marketing now play a critical role in preparing for 2030?

- What is the number one call to action for mold builders to get ready for 2030?

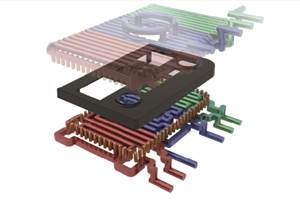

3. How do we bring conformal cooling to scale?

- How do predictive modeling, design and additive manufacturing impact conformal cooling?

- How are predictive engineering models applied to this process?

- Can you explain the algorithm and what it reveals about hot spots and conformal cooling design?

- What problems does it solve?

4. How has our training model changed?

- What is moldmaking versus mold manufacturing?

- Who is a mold designer versus a mold engineer?

- What are seven essential skills and knowledge areas to incorporate into a cross-training program for future mold builders?

- Virtual training is another change brought on by COVID-19; what are some critical components to quality virtual training?

5. How do you apply 3D printing to mold venting?

- What are the issues with traditionally sintered steels?

- How does additive venting work?

- What are the benefits of additive venting inserts?

6. What is visual search?

- What are the three types of visual search?

- Where can a mold builder apply visual search within their current processes?

- What are the key benefits of visual search to a mold builder?

7. How do you improve overall equipment effectiveness (OEE) monitoring?

- What data and analytics challenges do mold builders face?

- What are the key attributes a mold builder wants in an OEE tracking and machine monitoring system?

- How are machine monitoring and analytics tools different?

- What can the data reveal?

- What are the key benefits?

8. How can data help you make better decisions?

- How would you describe the current supply chain disruption?

- What specific data points do you monitor to stay ahead of what is happening in supply chain management?

- What factors do you see impacting the sustainability of the mold manufacturing market?

- What data do you recommend mold manufacturers keep an eye on as we move into 2022?

Do you have a question you’d like the industry to answer? Reach out to me at cfuges@gardnerweb.com.

Related Content

Pennsylvania Mold Builder Doubles Footprint, Maintains Quality and Company Values

Quality Mold Inc. doubles its manufacturing footprint but maintains its private company values and structure, delivering quality and fast turnaround from mold design and build through sampling.

Read MoreHow to Use Simulation to Achieve a High-Gloss Surface Finish

Combining simulation, conformal cooling, and a rapid heat and cooling process can predict and produce the required surface finish for high-gloss plastic parts.

Read MoreA 3D Printing Retrospective

A personal review of the evolution of 3D printing in moldmaking throughout the past 25 years.

Read More3D Printing Technologies for Moldmaking Applications

3D printing technologies, from conformal cooling to complex mold building, are making an impact on the moldmaking industry, one innovation at a time.

Read MoreRead Next

Snapshot of Why Westminster Tool is MMT's 2021 Leadtime Leader Winner

Here is a quick look at some of the reasons this small advanced manufacturer took the title this year.

Read MoreDoes Your Digital Presence Truly Reflect Who You Are?

MoldMaking Technology is all about “What’s New and What Works in Mold Manufacturing.” What is your business all about, and does your digital presence match?

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More

.jpg;maxWidth=300;quality=90)