Photo Credit: (top left) Capture 3D, (top right) DMG MORI USA Inc., (bottom left) Shining 3D and (bottom right) Sandvik Coromant.

Below, MoldMaking Technology covers a selection of innovative technologies and services, including thermal simulation tools, vibration-dampening boring bars, digital inspection tools and more.

To view the full product post, click the linked titles, or find them in the “New Tech” section of the website. Additionally, check out more maintenance, repair and surface treatment tools our latest technology roundup.

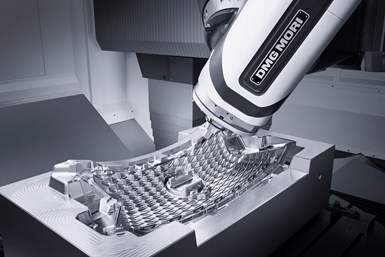

Plastic injection grill mold manufactured on a DMU 210 P. Photo Credit: DMG MORI USA Inc.

The plastic injection grill mold shown in the image to the right is produced on a DMG MORI DMU 210 P in a two-stage roughing and finishing process. Machining the 42CrMo4 steel component takes a total of 508 hours.

Due to the five-axis technology, 50% of the previous EDM process and 50% of the manual polishing work could reportedly be eliminated, and an overall accuracy of ±394 µin to ±984 µin could be achieved.

Photo Credit: Photo Credit: GF Machining Solutions, Fraisa and Braser Swisslube

Partners GF Machining Solutions, Fraisa and Blaser Swisslube have teamed up to develop a new graphite machining solution for moldmakers. GR3, said to be the answer for wet-machining graphite, supports the entire machining process—from electrodes right through to the finished molds—with a single setup.

The process, which uses an oil film to reduce the degree of contact between the graphite and the tool surface, increases the service life of the tool. The solution also helps moldmakers eliminate costly multi-machine operations, achieve 0.005 tolerances and better part finishes, provides a healthier work environment and optimize cycle times. It is also capable machining graphite, copper and steel on a single machine and without manual intervention.

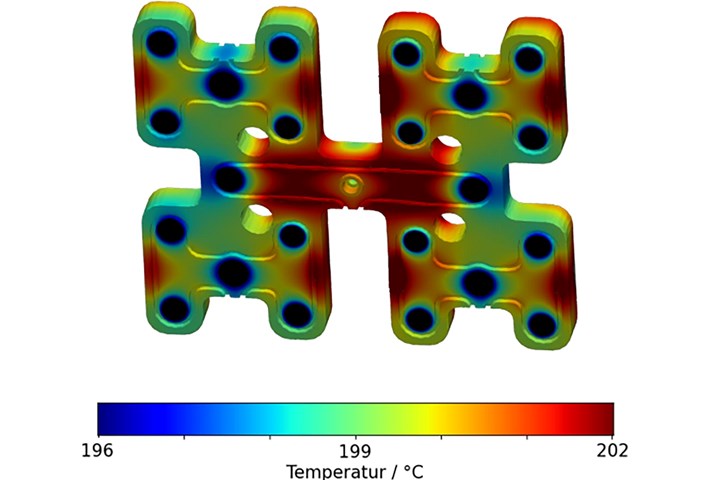

Hasco Hot Runner, a business unit of Hasco, has integrated a new simulation tool into its design process that reportedly enables an automatic and fast analysis. This avoids any loss of time in the creation of 3D data, and the customer receives the design data at the usual speed.

In combination with the already standard filling simulations and the experienced staff, Hasco Hot Runner says it offers its customers the best possible security for the individual challenges in hot runner technology.

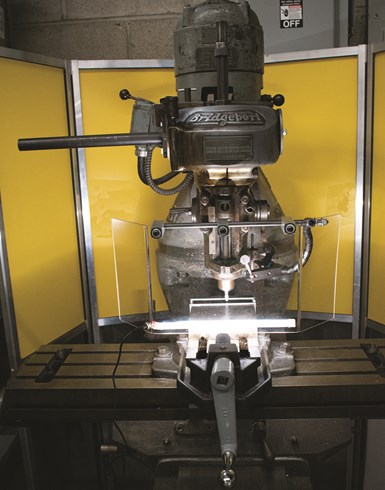

Photo Credit: Flexbar Machine Corp.

Flexbar Machine Corp.’s Visorguard-LED machine safety guards feature built-in LED lighting, providing machine operators with bright illumination of the working field. The safety guard’s continuous LED strip lighting is integrated as part of the safety shield to provide 6,000 kW of natural white light with a 170-degree beam angle. According to the company, the shield’s auto-diffuse lighting produces no LED light hot spots.

Walter USA has expanded its Accure∙tec anti-vibration boring bar line with the addition of the A3001 boring bar in combination with A2201 intermediate offset adaptor for larger diameter bores. It provides for fast, productive counterboring and internal profiling of parts in industries such as aerospace, oil and gas and general metalworking.

The standard A2201 is an offset adaptor for reduced radial forces, greater stability and provides more space between the boring bar and the bore wall for improved chip removal with very deep bores. With the A3001 and the A2201, Walter has increased boring bar diameters to 2.5-4" and 60-100 mm. Unlike conventional steel or solid carbide boring bars that are often ineffective at length/diameter ratios beyond 6xDc, Walter’s Accure∙tec A3001, with its patented vibration dampening system, is said to excel at length/diameter ratios beyond 6xD up to 10xD.

Photo Credit: Vision Engineering

Vision Engineering announces the launch of VE Cam, a simple-to-use compact digital inspection microscope for a wide range of applications. It made its North American debut at APEX Expo in January 2022.

The VE Cam is a complete, standalone system for circuit board examination, PCB debug activities or for discovering imperfections, and to trace problems in a wide range of industrial applications. It is ideal for applications from goods-in quality inspection to shop floor inspection of turned parts, and suitable for manufacturing electronics, plastics, ceramics, mechanical engineering and additive manufacturing (AM).

Photo Credit: Methods Machine Tools Inc.

Methods Machine Tools is now distributing Nakamura-Tome’s SC-100X2 twin-turret multitasking machine, which utilizes two tools on either side of the upper turret for superimposed machining. Methods spokespeople say this makes it well-suited for Swiss-style parts greater than 25 mm in diameter.

Operators can also use the upper and lower turret simultaneously, giving the SC-100X2 the flexibility of a true twin spindle machine. The machine’s design also contributes to a faster cycle time while maintaining precision and accuracy in line with other Nakamura-Tome machines.

Capture 3D presents the T-Scan hawk, a portable laser scanner that rapidly collects precision 3D data. The handheld 3D scanner offers GOM Inspect 3D inspection software, integrated photogrammetry, multiple laser sources and three application-focused scanning modes, providing the flexibility needed to accomplish various diverse tasks, including the scanning of a range of small to large molds.

As a lightweight, mobile, handheld 3D scanner, the T-Scan hawk is small enough to travel with and bring directly to the object it will scan, a benefit for mold builders when the mold is too large to move, or the object is fragile.

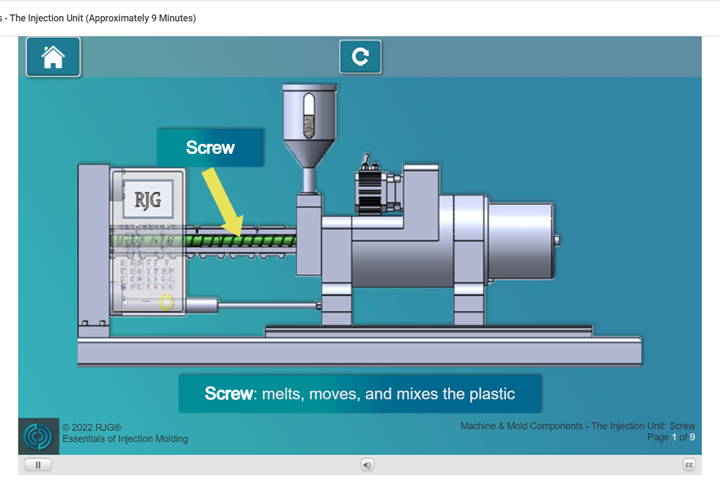

RJG Inc. announces the release of its new online “Essentials of Injection Molding” eLearning course, an introductory course in the RJG Training Academy and is offered in an interactive, self-paced platform. The online platform enables students to benefit from RJG’s training without travel costs or the need to spend time away from work. Interactive activities and problem-solving utilizes various learning styles in order to ensure maximum knowledge retention and provide tools that can immediately be put to use.

Photo Credit: Sandvik Coromant

Global metal cutting company, Sandvik Coromant, has launched an upgraded CoroDrill 860 cutting tool assortment to offer moldmaking customers improved productivity in drilling ISO P steels while significantly improving tool life.

The advanced -PM geometry is particularly ideal for medium hardness die steel in the mid-45 RC range (250-450 BHN). Sandvik notes that moldmakers would benefit using the 860-PM for higher volume production applications without the need to change out the tool as often, thereby reducing cost per component being drilled.

Digital manufacturing solutions provider, Shining 3D launches the novel high-precision stereolithography 3D printer, AccuFab-L4K 3D, and a high-resolution color 3D scanner, Transcan C 3D, with the goal of increasing 3D digital applications accessibility.

AccuFab L4K is a high-resolution 3D printer designed to improve prototyping efficiency and shorten the product development lifecycle. With 4K resolution and a large print volume, AccuFab-L4K is said to deliver ideal printing results and feasibility. The printer features extreme accuracy, reliable performance and multiple material options.

Photo Credit: HCL Technologies

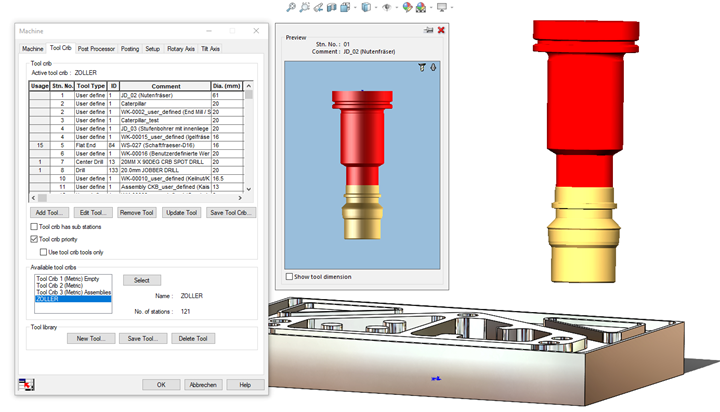

HCL Technologies (HCL), a global technology company, announces the implementation of Zoller TMS Tool Management Solutions Interface in HCL CAMWorks software. The Zoller Interface is said to supply customers with advanced tool database management options, an overview of available tools and eliminate the need to maintain multiple tool databases.

With the Zoller Interface in CAMWorks, tool data is standardized and the exchange of data between the two software systems is automated. Customers only need to enter the information for their cutting tools in once into the central Zoller tool database, HCL says, and the tools are imported automatically into CAMWorks.

_300x250 1.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)