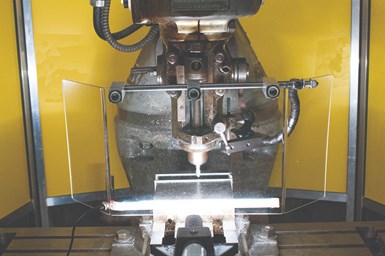

Machine Safety Shields Illuminate Working Fields

Flexbar Machine Corp.’s Visorguard-LED strip lighting is integrated as part of the safety shield to provide 6,000 kilowatts of natural white light with a 170-degree beam angle.

Photo Credit: Flexbar Machine Corp.

Flexbar Machine Corp.’s Visorguard-LED machine safety guards feature built-in LED lighting, providing machine operators with bright illumination of the working field. The safety guard’s continuous LED strip lighting is integrated as part of the safety shield to provide 6,000 kW of natural white light with a 170-degree beam angle. According to the company, the shield’s auto-diffuse lighting produces no LED light hot spots.

The company says the system is water- and coolant-proof, and installs in minutes on CNC mills, conventional mills, drill presses and more. The adjustable arm enables setting the shield at the correct height and angle for each setup, then locks rigid. The wing-shaped shield flips up to load a part and flips down for machining. A spring-loaded shaft enables the shield to stay put with no spring back.

The built-in LED lighting is powered through a choice of two system options. The first is a compact 12-V rechargeable battery pack (with an on/off switch) that is said to provide at least four hours of lighting per charge. The company says it can be easily attached to a side wing of the shield with included Velcro strips. A 12-V charger is also included. Another power option is a 12-V direct wire wall transformer with an eight-foot cable and on/off switch. All guards are said to meet or exceed OSHA requirements.

Related Content

-

How To Get Buy-In from Your Team for ISO 9001

Here are four tips for getting your team on board once you’ve decided to become ISO 9001 certified.

-

Treatment and Disposal of Used Metalworking Fluids

With greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are “consumable” and have a finite life.

-

VIDEO: What You Need to Know about the R&D Tax Credit Today

A team member from Strike Tax Advisory reviews the tax changes that are impacting the R&D credits for mold builders.

_300x250 4.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)