We started 2023 off strong with tips on hardening mold materials, mold design strategies and of course some great interviews with NextGen Mold Technologies and Zero Tolerance. Based on Google Analytics, we have pulled the top ten most-viewed pieces from last month. From what we gathered, there is something for everyone.

10. MMT Chats: 4 Keys to a Successful Mold-Building Operation: Innovation, Transparency, Accessibility and Relationship

MoldMaking Technology Editorial Director Christina Fuges chats with Steve Michon, co-owner of Zero Tolerance in Clinton Township, Michigan, about the excitement of solving problems, the benefits of showing gratitude, the real struggle with delegation and the importance of staying on top of technology. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

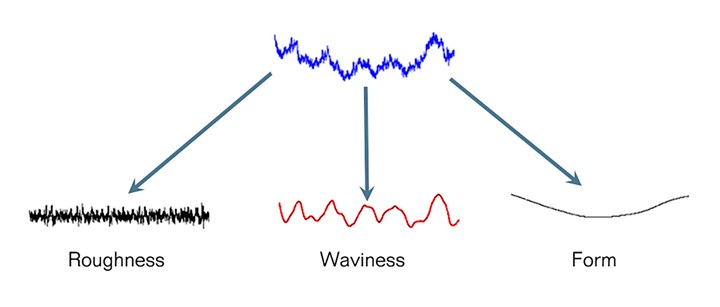

9. What Does Surface Roughness Mean in Moldmaking?

To improve mold performance, reduce wear and produce high-quality molded parts, mold builders must understand surface texture and how to properly measure, analyze and control it.

Surface texture is separated into roughness, waviness and form.

Photo Credit: Digital Metrology Solutions

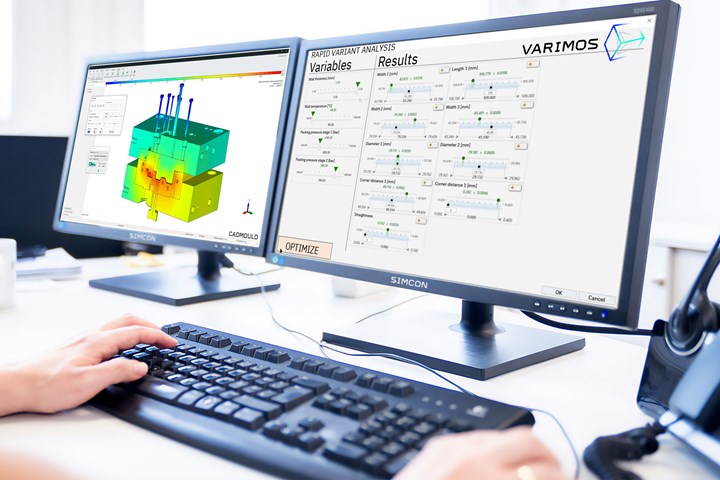

8. Simulation is a Process, Not Just Software

To reap the benefits of simulation, you must view it as a process requiring you to change the way you work in part and mold design.

7. What's New with MoldMaking Technology in 2023?

Although MMT remains focused on its engineer, build, maintain and manage tagline, we are adding some new elements to freshen up the content, engage the reader and point out essential educational articles.

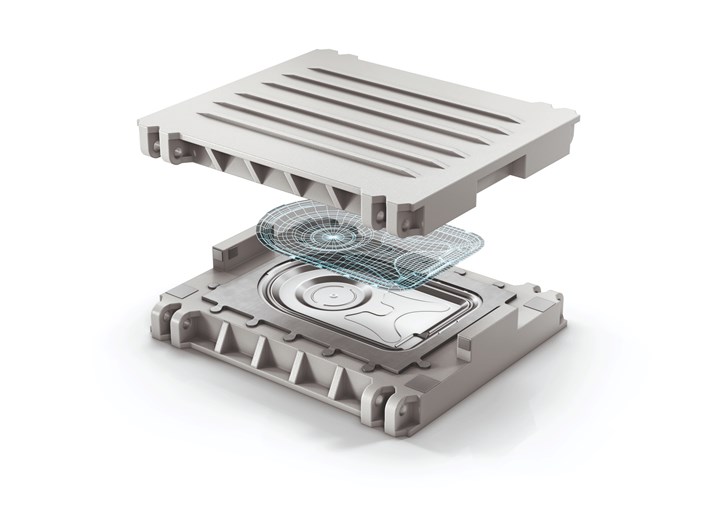

6. How Hybrid Tooling Accelerates Product Development, Sustainability for PepsiCo

From our sister brand, Additive Manufacturing: The consumer products giant used to wait weeks and spend thousands on each iteration of a prototype blow mold. Now, new blow molds are available in days and cost just a few hundred dollars.

5. How to Polish Ribs for Proper Part Release

Using the right tools and abrasives is essential to polish a mold to the required final finish.

4. MMT Chats: 5 in 5 with Zero Tolerance

MoldMaking Technology Editorial Director Christina Fuges gets leading mold builders to reveal 5 best practices for improving efficiencies in culture, technology, process, measuring success and staying competitive ... in 5 minutes. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

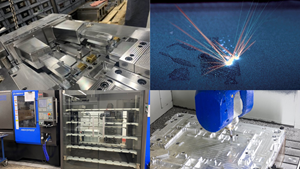

3. Three Ways to Accurately Machine Hardened Mold Materials

Three cutting tool design considerations to improve process reliability and cost efficiency when deep-hole drilling molds.

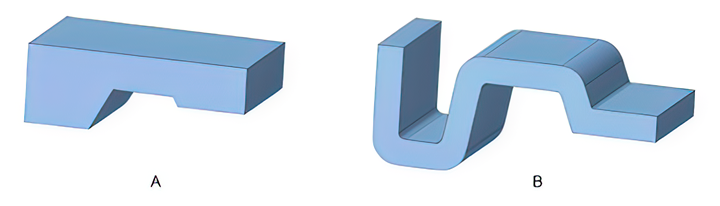

2. How to Manage Wall Thickness Changes in Your Mold Design

To ensure even filling and cooling, consider wall section transitions, corners and fillets, ribs and bosses, lip and rim designs and CAE flow simulation software.

1. Next-Generation Thinkers Redefine Moldmaking Quality and Service

Canada-based NextGen Mold Technologies is a new mold shop using excitement and empowerment to encourage better ideas every day.

Related Content

3D Printing Speeds Prototyping and Shifts Talent to Production Tooling

A digital approach to prototyping using 3D-printed tooling accelerates product development and frees up mold builders for production tooling work.

Read MoreMold Materials, 3D Printing Technologies for Next-Gen Moldmaking

As moldmaking advances, so too do the materials and processes involved in their efficient production, including these latest mold materials and 3D printing technologies.

Read MoreHow to Design a Mold with Additive Tooling

Designing molds with additive tooling implementation in mind requires blending traditional mold standards with innovative new ideas of what is possible to push the limits of mold performance.

Read MoreMoldMaking Technology's Most-Viewed Case Studies of 2023

MoldMaking Technology’s case studies present a shop’s problem, solution and results in thorough detail. Take a look at our top five most-viewed case studies based on Google Analytics.

Read MoreRead Next

Five Strategies to Make Automation Affordable

Mold manufacturers can maintain their competitive edge by making smart capital investments in times of crisis.

Read MoreMore Than Moldmaking at PTXPO 2023

The Moldmaking Pavilion returns to the Plastics Technology Expo (PTXPO) March 28-30, 2023, at the Donald E. Stephens Convention Center in Rosemont, Illinois, but there’s more to discover than moldmaking.

Read MoreMMT Chats: Mold Design Apprentices Speak Out

Mold Design Apprentices Alex McClinton and Nolan Benedict share their individual journeys to moldmaking, impressions of a unique mold design apprenticeship and their future plans.

Read More