Latest Mold Analysis Software Meets Injection Molding Needs

Coretech Systems’ Moldex3D 2023 strengthens simulation performance, provides user-friendly interfaces and cloud services, streamlines workflow and strives to connect the virtual to the real.

CoreTech Systems responds to the transformational needs of plastic injection molding through Moldex3D 2023, its latest version of the molding analysis software. The new generation focuses on four main concepts: reliability, efficiency, augmentation and liberation.

Moldex3D 2023 continues to improve simulation performance. The Moldex3D Forming Technology R&D Center has conducted real injection experiments using nearly 400 different materials to optimize parameters in the material library, enhance reliability and make the results of molding analysis closer to reality.

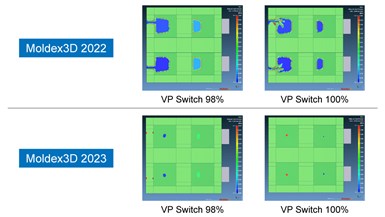

In terms of molding analysis, Moldex3D 2023 upgrades venting analysis, including compressibility and air temperature calculation. It accurately simulates the temperature and pressure changes of air in the mold cavity during the filling process, enabling users to plan and compare various venting designs, avoiding defects such as short shots and burn marks.

For cooling channel, users can directly set parameters to automatically build baffle and cooling channel mesh, supporting the establishment and simulation of manifold, which can add cooling tube outside the mold to consider the actual influence of the mold temperature controller in simulation.

Moldex3D 2023 also supports parallel computing on multi-core processors, multiple processors and clusters.

Moldex3D Cloud-Connect reportedly helps users deploying the latest version of Moldex3D on AWS, Azure and Google within just 40 minutes, and can adjust the calculation scale according to demand, making work easier. In addition, Cloud-Connect also supports automatic on/off functions, ensuring enterprises can save up to 72% of costs during the period of timed plans. Introduction of the Moldiverse cloud platform, where users can access services such as MHC, iMolding and University, commits Moldex3D to providing a precise, reliable molding analysis experience.

Moldex3D 2023 also strives to meet customers demands for virtual and real integration. The Moldex3D iSLM allows enterprises to establish a big data database, effectively manage work assignments and project schedules and create their own quality indicators to quickly determine product quality. This year, users can search models by uploading CAD files, saving time and efforts on searching and comparing files throughout the database. In addition, Moldex3D integrates with injection molding machines from FANUC and Sumitomo.

Additional features and support aim to solve complex manufacturing challenges, related to the MCM dual-shot optical simulation function, two viewing output options, the support of file formats from LS-DYNA or Abaqus and support in assisting customers in converting simulation data into product insights more quickly and easily. Moldex 3D also has an API feature to automatically execute high-repetition processes and molding parameter settings during experimentation and verification (find more details about these features here).

Related Content

-

Power Sliding Clamps Enable Faster Mold Changes

Distributed in North America by Globeius Inc., the MouldPro Power Sliding Clamps can accommodate a range of different mold backplate sizes and thicknesses.

-

MMT Chats: Molds, Molding, Marketing and Membership

MoldMaking Technology Editorial Director Christina Fuges chats with Eric Hecker, Sales and Project Engineer for Eifel about his focus on sales and marketing, the move into molding, technology and training trends and his mission to help increase membership in Mold Technologies Division of SPE. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

-

Molds, Hot Runner Systems, Digital Technologies Highlight Sustainable Production

The Molding Solutions network at K Show displays Männer, Foboha, Synventive, Thermoplay, Priamus, Gammaflux and other external partners and their new or proven technologies for molding and moldmaking.

.png;maxWidth=300;quality=90)